Okuma Multus B550-W CNC Lathe, 2016 – Big Bore, Installed 2018, Renishaw Probing

$689,900.00

This product is no longer available. For additional information, please fill out the form below.

Control: Osp-P300s-H Cnc Control

Max Machining Diameter: 32.68″

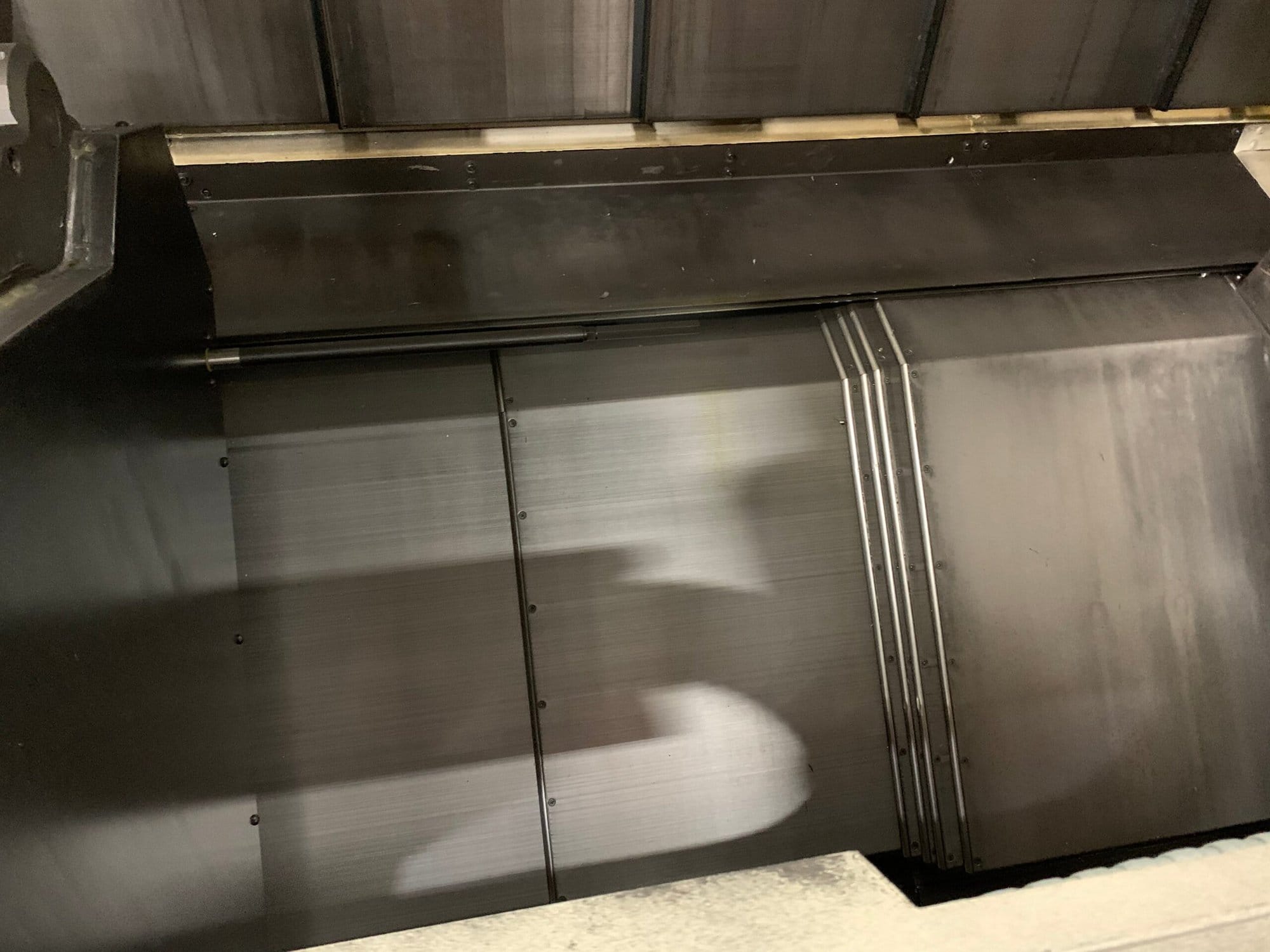

Max Center Distance: 118.11″ (3000mm)

X-Axis Travel: 36.42″

Z-Axis Travel: 126.57″

Y-Axis Travel: 20.47″

W-Axis Travel (sub Spindle): 122.05″

B-Axis Head Swivel: -30° / +210°

B-Axis Tilt Resolution: 0.001° Resolution

Full C-Axis Programmable Main And Sub Spindle

Live Milling Spindle Speeds: 40-10,000 Rpm

Tool Changer Capacity: 80 Stations

Milling Tool Holder: Capto-C8

Live Milling Drive: 50/40/30 Hp

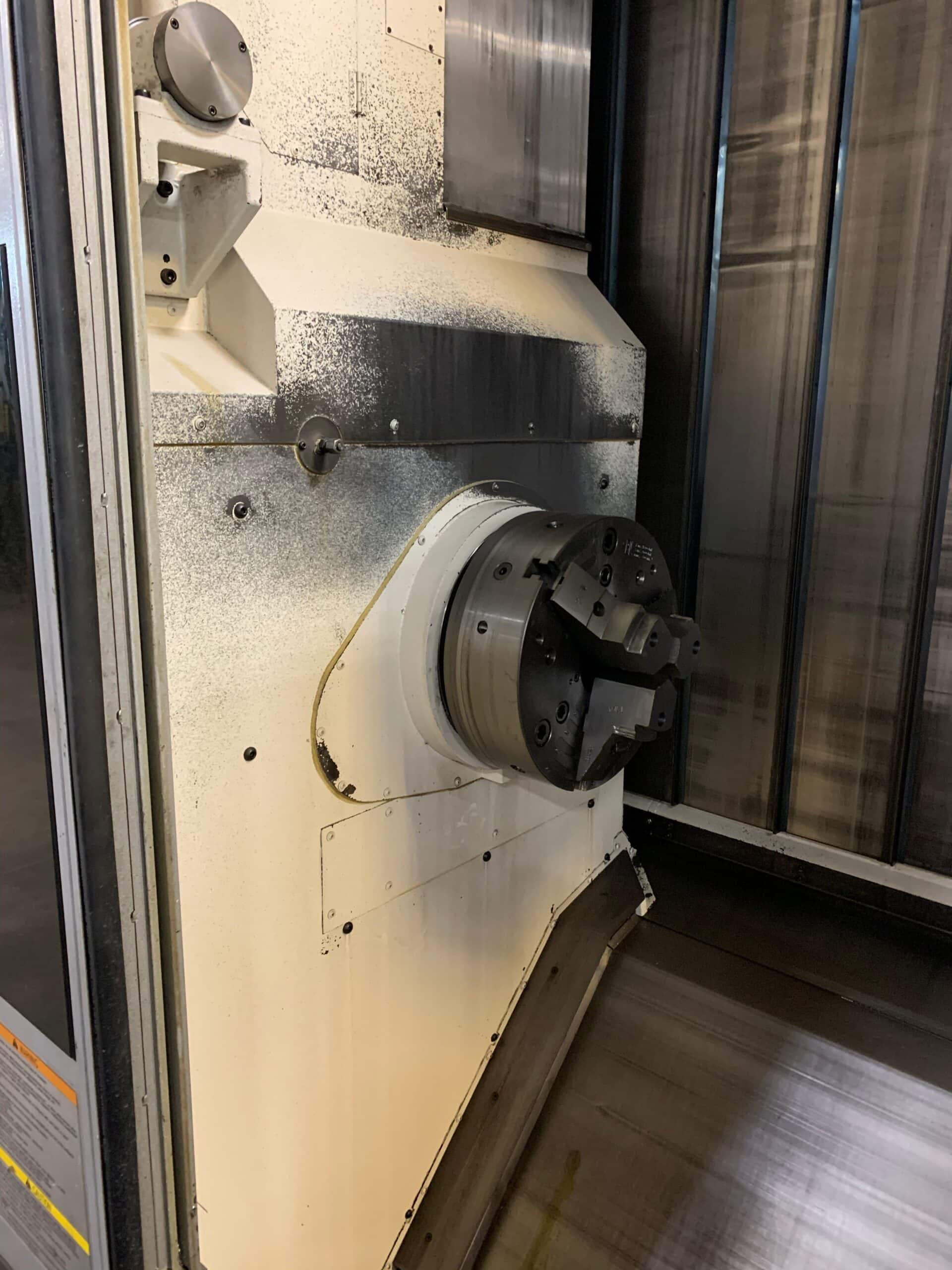

Workholding (left & Right Spindles): Schunk Rota Thw 400-120 15″ 3-Jaw Chucks With 4.72″ Spindle Hole

Turning Spindle Speeds: 24-2400 Rpm

Turning Spindle Nose: Jis A2-11

Turning Spindle Drive: 50/40 Hp

Turning Spindle Bar Capacity Left Spindle Only: Kitagawa F2511h 4.625″ Inner Diameter

Left And Right Spindle Inner Diamter: 5.12″ Spindle Id

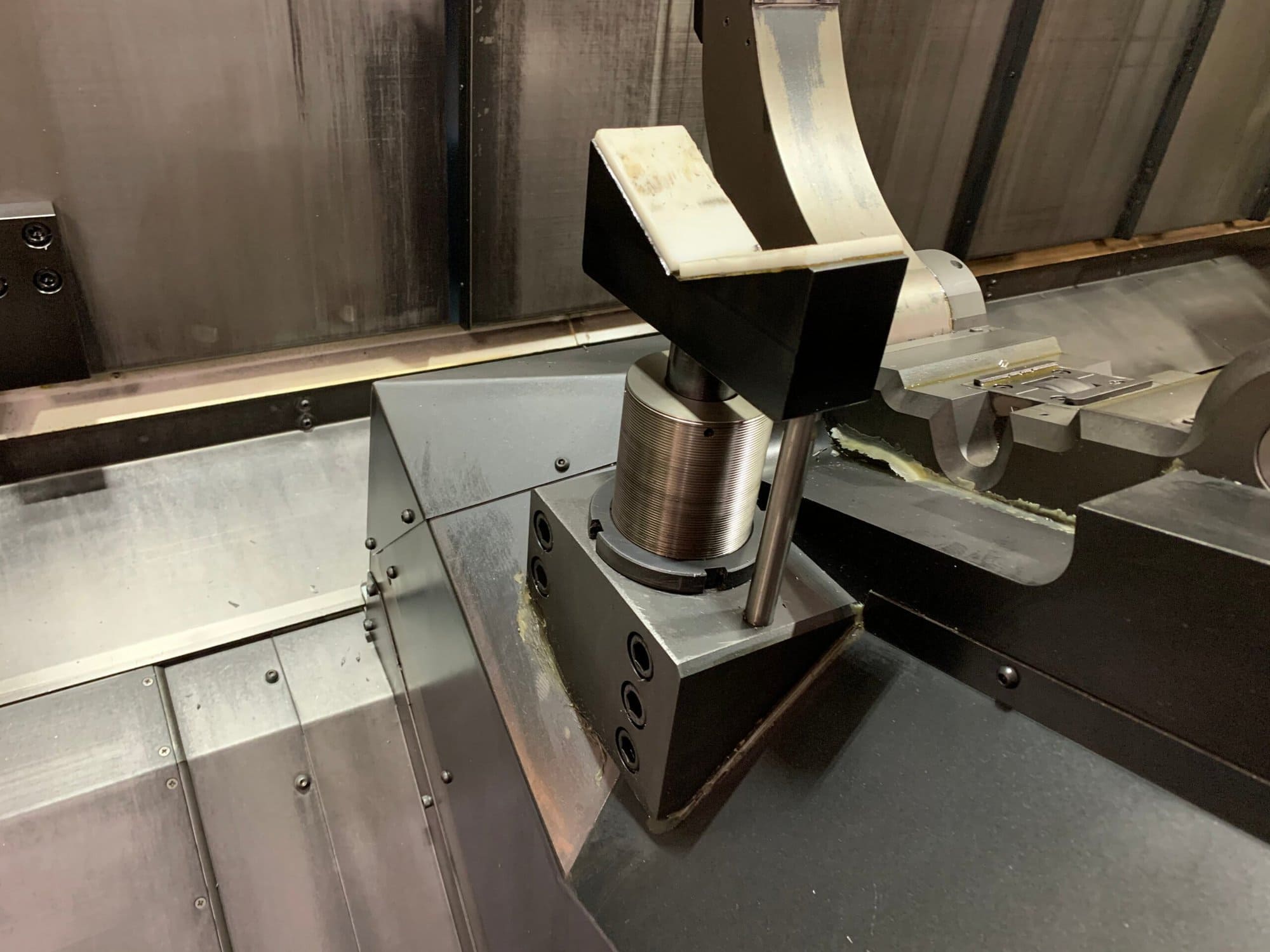

Programmable Steady Rest: Lns Model Slux-Z-5.1 3.35″ To 13.78″ Capacity

Rapid Traverse Rates: (x, Y, Z) – 1574.8 Ipm (w ) – 590.5 Ipm (c) 200 Rev/min (b) 30 Rev/min

Equipped With:

Okuma Osp-P300s-H Cnc Control

3000mm Between Centers Option

Dual Big Bore

50hp

2400rpm Left And Right Spindles With Full C-Axis And Sub Micron Control,

Dual Schunk Rota Thw (15″) 400-120 3-Jaw Chucks

10,000 Rpm

50hp Capto-C8 B-Axis Milling Head With 80 Station Tool Changer Option

Renishaw Auto Gauging Rmp 60 Parts Probing Kit

Automatic Tool Touchsetter

Smw Slux-Z-5.1 Programmable Steady Rest

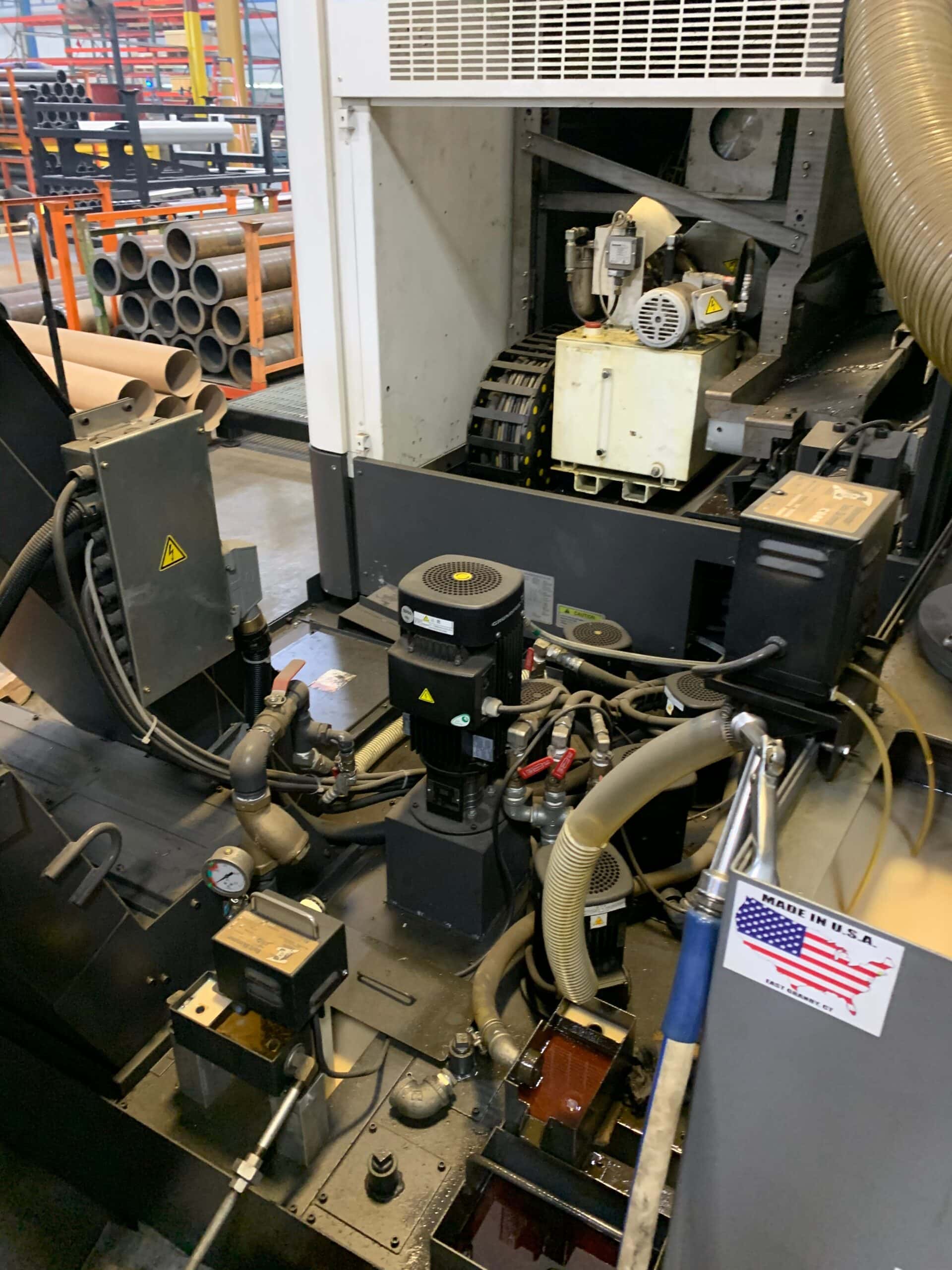

Mp Systems Vr8 1000 Psi High Pressure Coolant System

Mp1200 Mist Collector

Drum Filter Chip Conveyor System

Multiple Daikin Inverter Chillers

Control Options:

Gear Cutting Software Package

Okuma Osp-Suite

Tas-C Thermo Active Construction Stabilization

Tas-S Thermo Active Spindle Stabilization

Slope Machining B-Axis Function

Okuma Collision Avoidance System

Torque Skip Load Sensing Function

Pitch Error Compensation X+z Axis

Machine Manuals