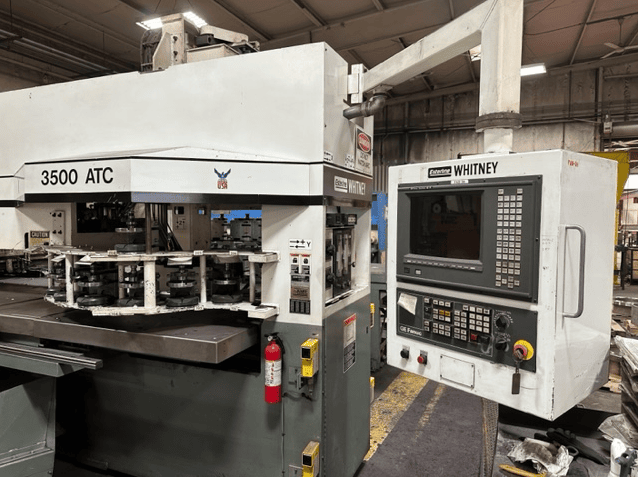

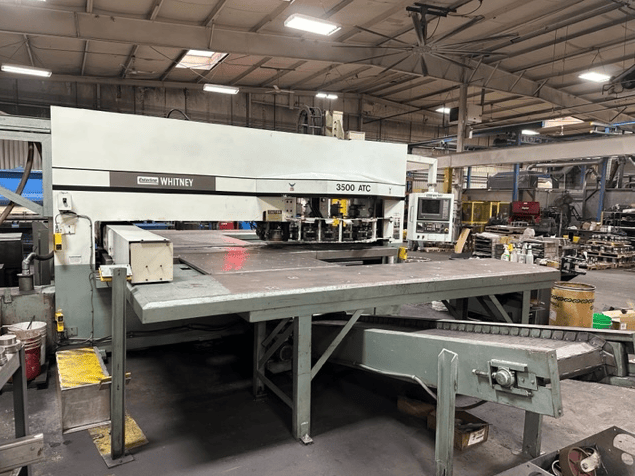

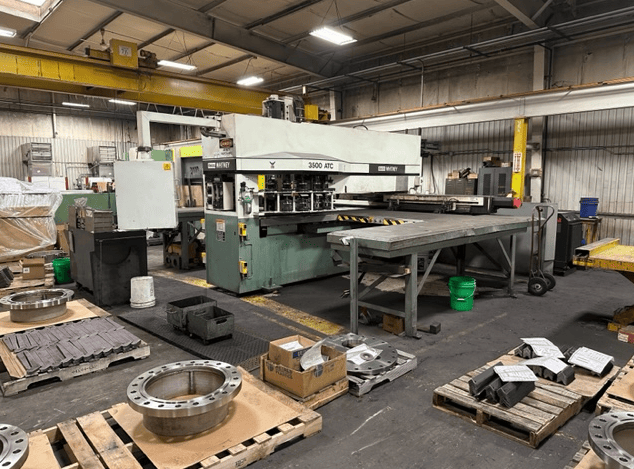

50″x 90″, 40 Ton Whitney Model 3500 ATC Punch/Plasma Fabricating Center, 2000 – True Cut Plasma Cutting System, with GE Fanuc 16P Control

$29,900.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: Turret Punches

Make: Whitney

Model: Model 3500

Year: 2000

Capacity: 0 Ton

Machine Location: Indiana

Stock #: 613067

WHITNEY 3500 ATC PLASMA PUNCH

PUNCHING FORCE: 40 TONS

MATERIAL THICKNESS

MIN. 0.035″

MAX. 0.500″

MAX. PUNCH DIAMETER

OR EQUIVALENT SHAPE 5.000″

PUNCHING CAPACITY

0.250″ MATERIAL= 5.000″

0.375″ MATERIAL= 2.750″

0.500″ MATERIAL= 1.000″

HIT RATE AND ACCURACY (IN 10 GAGE MATERIAL)

ON 1″ CENTERS: 165 HPM

POSITIONING AREA:

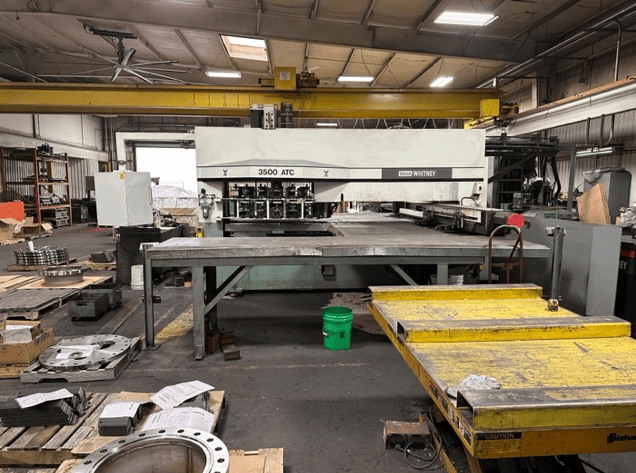

X-AXIS: 90″

Y-AXIS: 50″

POSITIONING SPEED:

PER AXIS: 1,200 IN/MIN

POSITIONING ACCURACY:

POSITIONING AREA: +- 0.005″

MAX PIECE PART

1200 IPM= 650 LBS.

MAX. BLANK SIZE:

W/ NO AUXILLARY TABLES 50″X72″

WITH (2) AUXILLARY TABLES 50″X120″

MAX. HEIGHT

TOOL CHANGER 130″

PRESS FRAME AND POWER ISLAND 97″

EQUIPPED WITH:

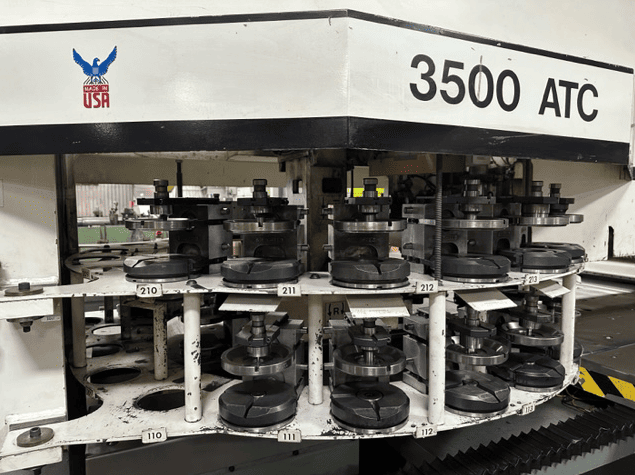

ALL TOOLING AND DIE SETS INCLUDED (75+ TOOLS)

SHIPPING WEIGHT: 45,000 LBS.

MACHINE DIMENSIONS: 300″X230″ (BASE MACHINE ONLY)

*New conveyer belt system.

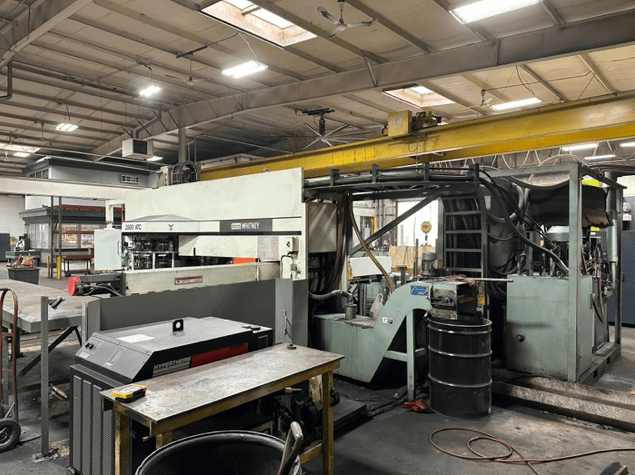

*Upgraded Hypertherm unit.

*Complete manuals included.

*Regular PM’s per prescribed schedule.

*Heavy duty auxiliary ball transfer table.

*All tooling and die sets included (75+ tools).

*Powered small parts and/or scrap conveyor.

*Powered slag conveyor (in lieu of manual cleanout tank).

*Machine currently not in regular use, but still under power

All specifications are assumed to be correct but must be confirmed by the purchasing entity.