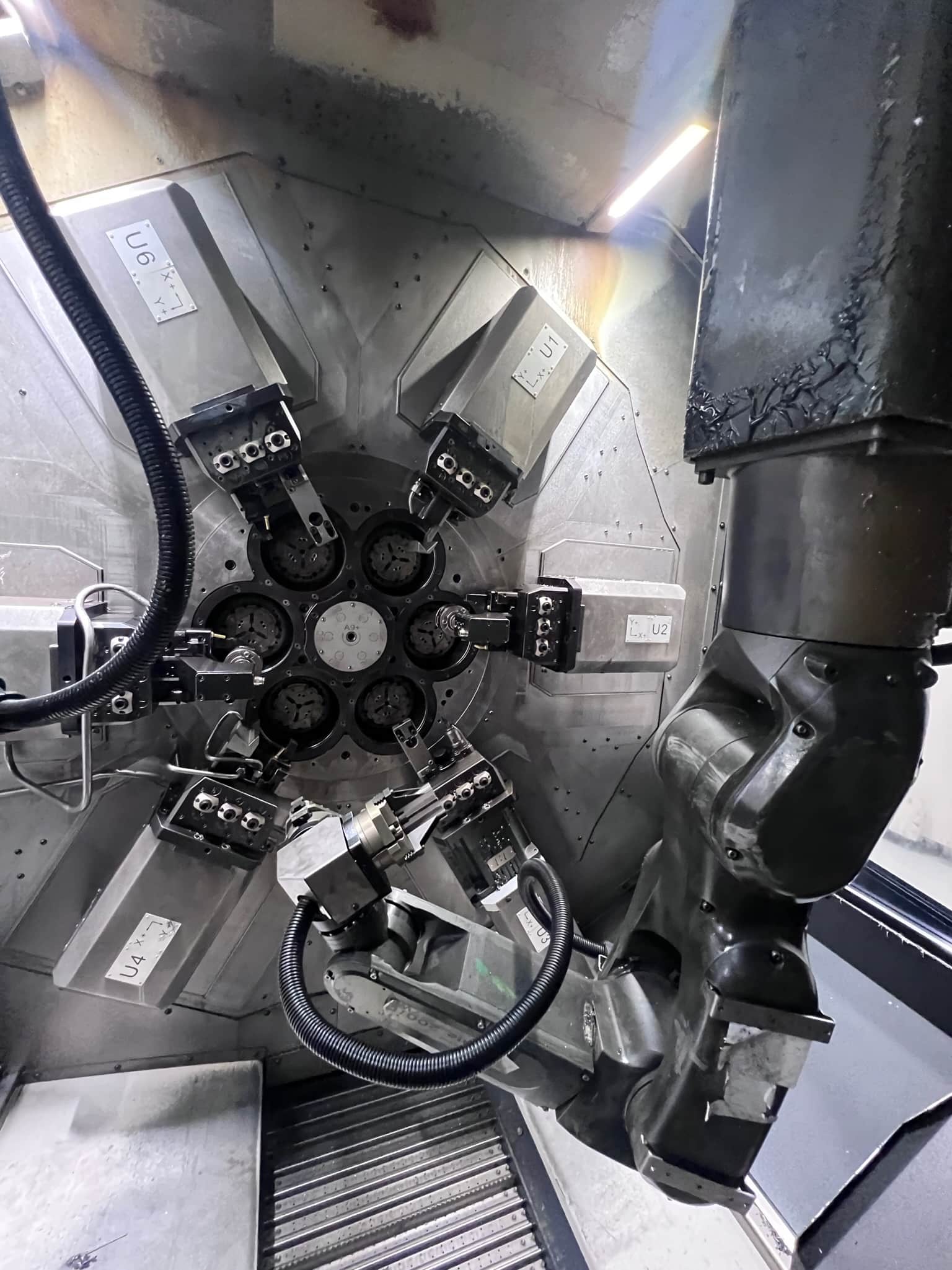

DMG Mori Multisprint 36 CNC Multi Spindle Lathe, 2019 – High Pressure Coolant, Chip Conveyor, Oil Mist Collector, (2) Fanuc Robots Included

$829,900.00

This specific product is no longer available, however we may have other similar or identical products in stock. Please utilize our search function at the top of the page to check and confirm, or fill out the form below:

Max Bar Capacity: 1.41″ (36mm)

Max Bar Feed: 3.93″

Max Bar Feed with SWISSTYPEkit (code I-B1270): 7.08″

Number of Work Spindles: 6

Spindle pitch Circle Diameter: 14.96″

Max Spindle Speed: 7500 RPM

Spindle Power: 20 HP

Bar Max Length: 0.13″

Bar Min Loading Length: 0.09″

Number of Units (Cross Slides with X – Y Axes Movements): 6

X-Axis Max Travel Pos.1-6: 1.96″

Y-Axis Max Travel Pos.1-6 mm: +/- 1.96″

Main Spindles Z-Slides

Number of Slides: 6

Z-Axis Travel: 3.93″

Z-Axis Travel Max. Travel with SWISSTYPEkit (code I-B1270): 7.08″

Machine Weight: 33,000 Lbs.

Machine Dimensions: 401.57″ x 84.65″

Equipped with:

Fanuc 30i-B Control

Chip Conveyor, Hinged Type

High Pressure Device 0,25/5/12 MPa

Oil Mist Collector for Oil/Emulsion

Tool-holder Block with no.3 Quick-Change Junctions

Motor Drive for Tool-Holders 8.000 rpm

Chiller System for Machine & High Pressure Device

(6) Collet appl. Hainbuch TOPlus 40 W/O Axial Movement

Manual Collet Replacement dev. Hainbuch TOPlus 40

(12) Clamping Collet Type Hainbuch TOPlus 40 Max d.36

Drill/Boring-holder Ø25mm pos.TH02 Main Spindles

(8) Tool-holder ext. for KM32 for Main Spindles

Drill/Boring-Holder Ø25mm pos.TH03 Main Spindles

Radial Driven Unit 3900 rpm, Ø16, ext. Cooling

G-Interface for Blank Loading Device

Transformer

DMG MORI SMARTkey – Turning Package (4 keys)

G- Set of (2) Fanuc Robots in the Working Area for the Workpieces Loading/Unloading

G-Set of (2) Axial Rolling Head FETTE Type

with (2) Sets of Rollers, Pneumatic Device

for Mechanical Reloading

G-Special Device for Part Feeding,

Assembled on the Slide, Complete

with Arm and Adaption

G-Adaptor for Presetting Outside the Machine

SK011 G-Interface for Blank Loading Device,

Including Signal and Blank Handling in the Machine

Other Available Tooling