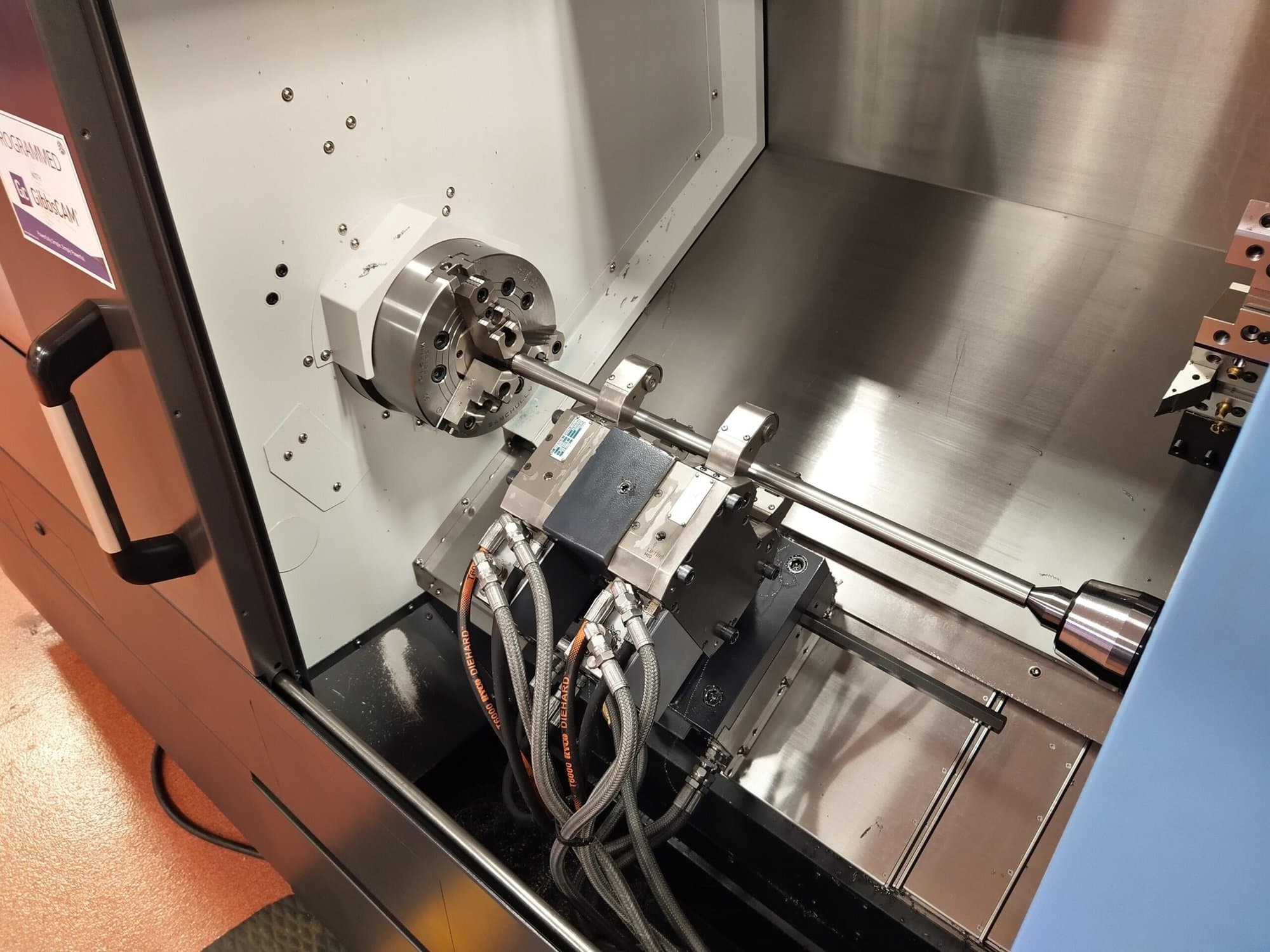

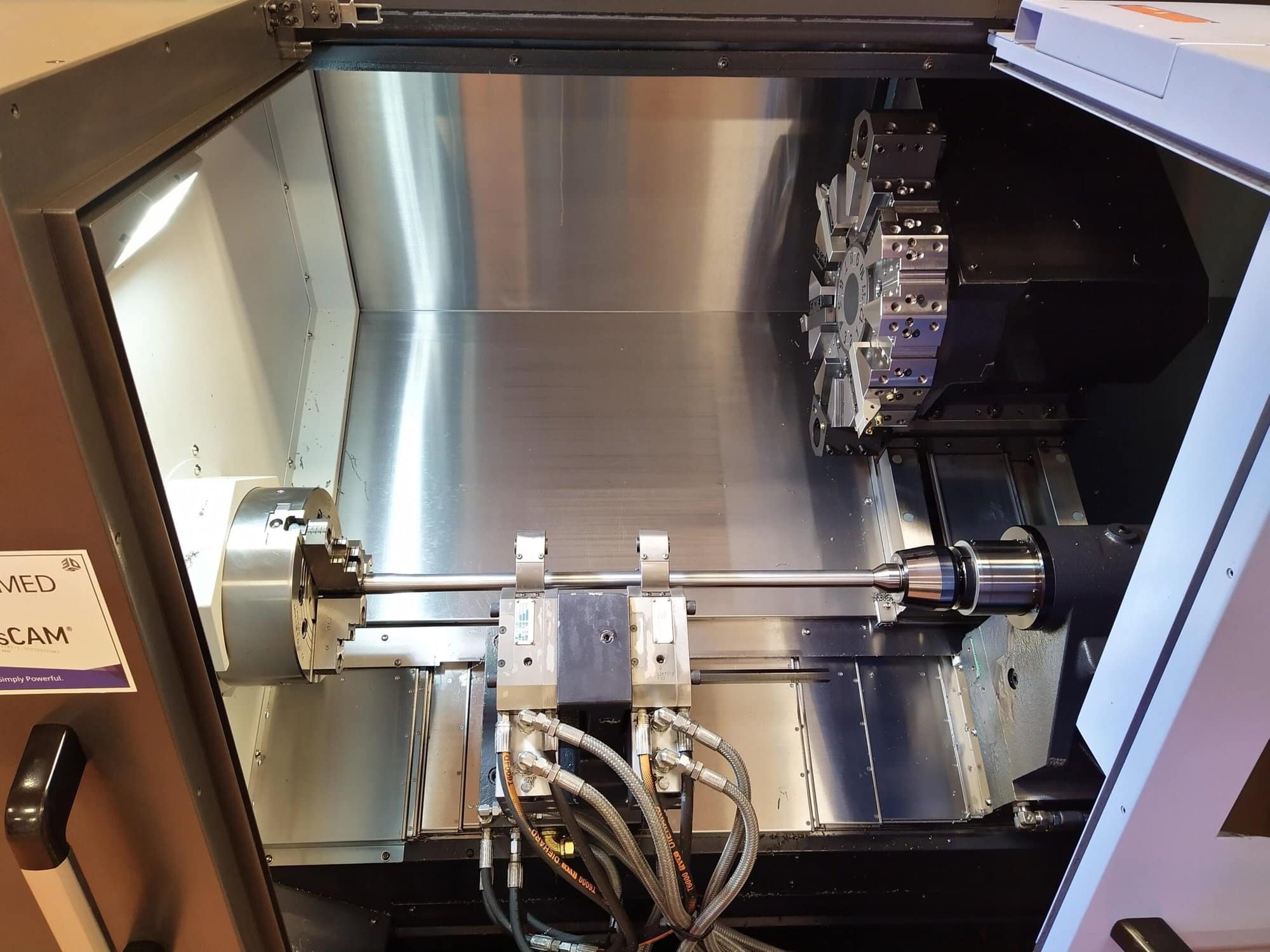

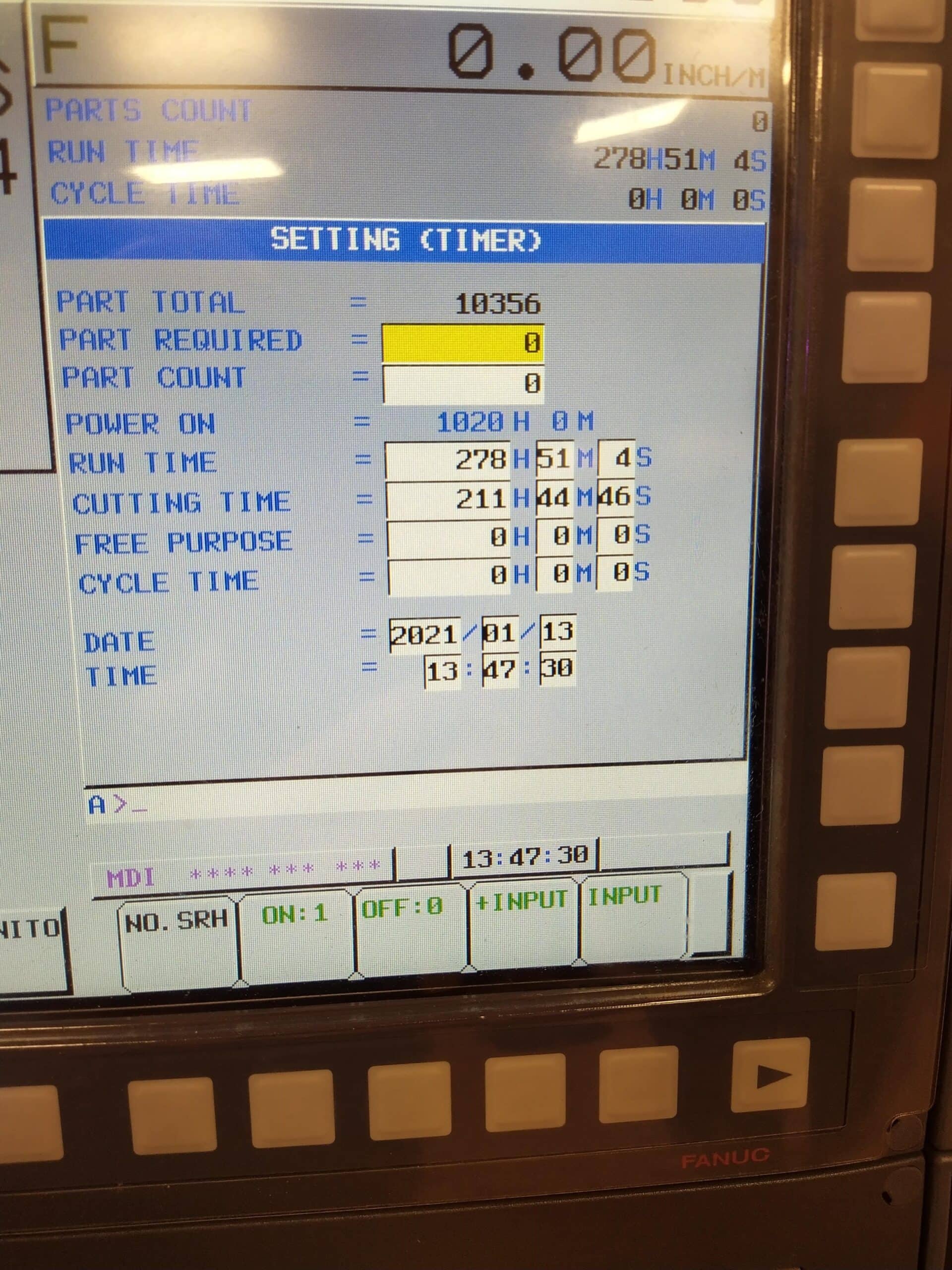

Doosan GT2600L CNC Lathe, 2018 – Programmable Tailstock, Tooling Included, Only 200 Hours!

$89,500.00

This specific product is no longer available, however we may have other similar or identical products in stock. Please utilize our search function at the top of the page to check and confirm, or fill out the form below:

CAPACITY:

Swing over bed: 630 mm (24.8″)

Swing over carriage: 460 mm (18.1″)

Maximum turning diameter: 460 mm (18.1″)

Maximum turning length: 1078 mm (42.4″)

Distance between spindle nose and tailstock center: 1,263 mm (49.7″)

SPINDLE:

Spindle speed: 3,500 rpm

Spindle nose: A2-8

Draw tube: ID82 mm (3.23″)

Standard chuck through hole: ID82 mm (3.23″)

Spindle bore diameter: 91 mm (3.58″)

AC spindle motor: (30 min. rating)22 kW (30 hp)

Maximum spindle torque: (15 min. rating)622 Nm (459 ft-lb)

Standard chuck size:254 mm (10″)

BED, SADDLE & CROSS SLIDE:

Angle of slant bed: 30 degree

X axis travel: 265 mm (10.43″)

Z axis travel: 1,100 mm (43.3″)

X axis guide way span: 255 mm (10.0″)

Z axis guide way span: 360 mm (14.2″)

X axis rapid traverse rate: 24 m/min (945 ipm)

Z axis rapid traverse rate: 30 m/min (1,181 ipm)

X axis ball screw diameter: 32 mm (1.26″)

Z axis ball screw diameter: 40 mm (1.57″)

X axis feed thrust (continuous): 6,761 N (1,520 lb)

X axis feed thrust (intermittent): 9,465 N (2,127 lb)

Z axis feed thrust (continuous): 12,414 N (2,791 lb)

Z axis feed thrust (intermittent): 17,379 N (3,907 lb)

X axis repeatability: ±0.002 mm (±0.00008″)

Z axis repeatability: ±0.003 mm (±0.00012″)

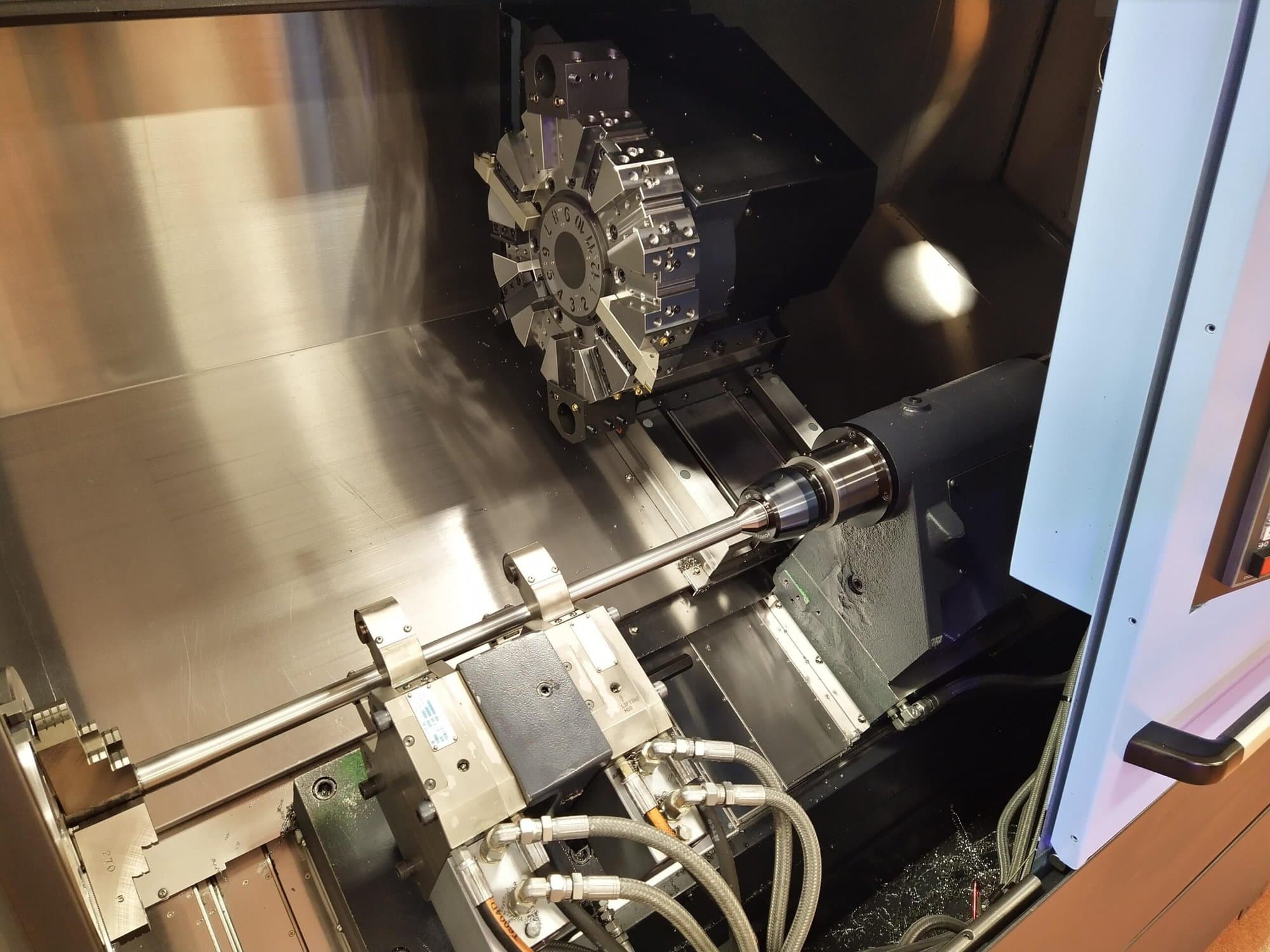

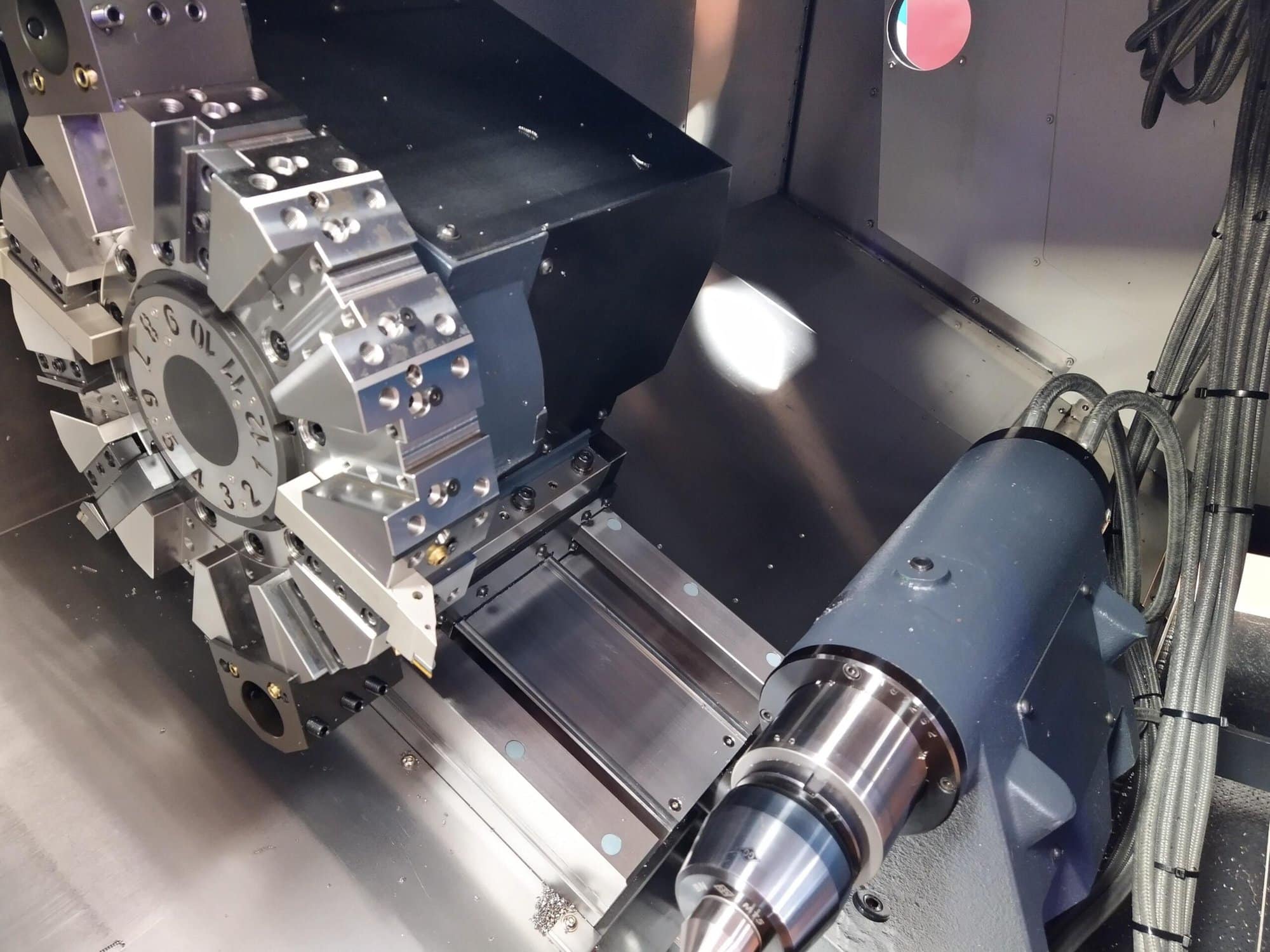

TURRET:

Number of tools: 12

Tool holder type: BMT-KEY

Turning tool shank size: (metric turret 25 mm) 1.0″

Boring bar diameter: (metric turret 50 mm) 2.0″

Turret index time: (next station swivel time)0.15 second

Tool selection: Bi-directional

Curvic coupling diameter: 203 mm (7.99″)

Turret clamping force: 53 kN (11,915 lb)

Turret index repeatability: ±0.0005 degree

TAILSTOCK:

Tailstock center: MT #5 live

Tailstock quill diameter: 100 mm (3.94″)

Tailstock quill stroke (programmable): 100 mm (3.94″)

Maximum tailstock quill thrust: 11 kN (2,473 lb)

Maximum tailstock hydraulic pressure: 40 bar (580 psi)

Tailstock guide way span: 235 mm (9.25″)

COOLANT SYSTEM:

Coolant pump pressure: 4.5 bar (65 psi)

Coolant pump motor: .75 kW (1.0 hp)

Coolant tank capacity: 268 l (71 gal)

HYDRAULIC / LUBRICATION:

Hydraulic tank capacity: 13 l (3.4 gal)

Hydraulic oil required: *Mobil DTE #24 or Shell Tellus 32

Way lubrication tank capacity: 2.0 l (0.5 gal)

Way lubrication oil required: *Mobil Vactra #2 or Shell Tonna T68

GENERAL:

Machine weight: 5,700 kg (12,570 lb)

Floor space – length x width: 3,735 mm x 1,630 mm (147″x64.2″)

Floor space – length with hinge belt chip conveyor: 4,953 mm (195″)

Machine Height: 1,720 mm (68″)

Height from floor to spindle center: 1,047 mm (41.2″)

Voltage required: 205-235V/3 ph/60 Hz

Power requirement: 39 kVA (102 Amps @ 220 Volts)

Equipped With:

• Standard chuck specification: MH-210 10″ Samchully 3-jaw chuck. 254 mm (10″) diameter with 82 mm (3.23″) bore, 4.4 mm (.173″) jaw stroke – includes one set of soft jaws

• Hydraulic chuck actuator: SD-18582 with 82 mm (3.23″) through hole

• Programmable hydraulic tailstock (body clamp, drive pin and quill) – MT #5 live center

• Rigid tapping

• 65 psi multi-stage coolant pump

• Separate coolant tank with way lube oil skimmer

• Automated metered lubrication system

• P4 class spindle bearings and P4 class angular thrust bearings

• 580 psi hydraulic unit

• Safety features: fully enclosed work area, door interlock, hydraulic pressure safety switch, spindle Interlock, program protect, chucking signal

• 3 color signal tower and work light

• Tool box with operating tools

• Leveling bolts and plates

• Operation manuals, maintenance manuals, parts list, electrical drawings and factory test report

Tooling Included:

850418-00864 Tool holder – OD Extended – (R & L) (1″ sq)

2

L32510647C Tool holder – OD Face – (R & L) (1″ sq)

2

L31510617A Tool holder – OD – Wedge clamp (1″ sq)

2

L32510637G Tool holder – ID – 2.000″ ID

6

L32590517F Sleeves – Boring bar (6 pc kit) – 2.000″ OD X (0.500, 0.625, 0.750, 1.000, 1.250 & 1.500″ ID)

1

L33590577D Sleeves – U-Drill (4 pc kit) – 2.000″ OD X (0.750, 1.000, 1.250 & 1.500″ ID)

1

L32516103 Cap – U-Drill for ID holder – coolant through the drill / boring bar