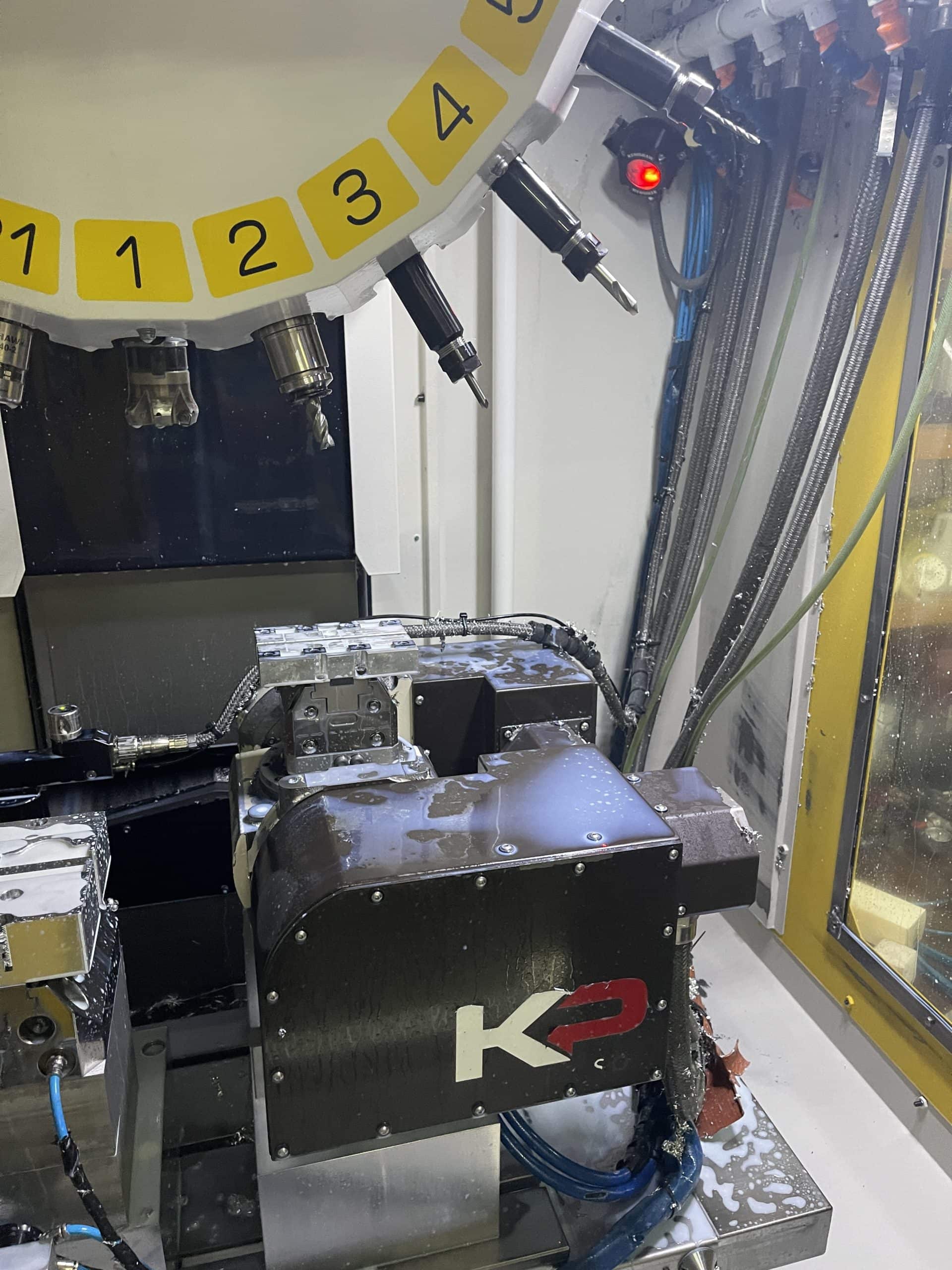

Fanuc RoboDrill 5X A-D21MiB5 CNC VMC, 2018 – Low Hours, 5th Axis, 24K Spindle

$119,900.00

This specific product is no longer available, however we may have other similar or identical products in stock. Please utilize our search function at the top of the page to check and confirm, or fill out the form below:

Manuals (1) Each: Operators, Maintenance, Parts, Operators CNC, &

Maintenance CNC

MistBuster Mist Collector

Interior Work Light – LED STYLE

21 ATC 24k RPM

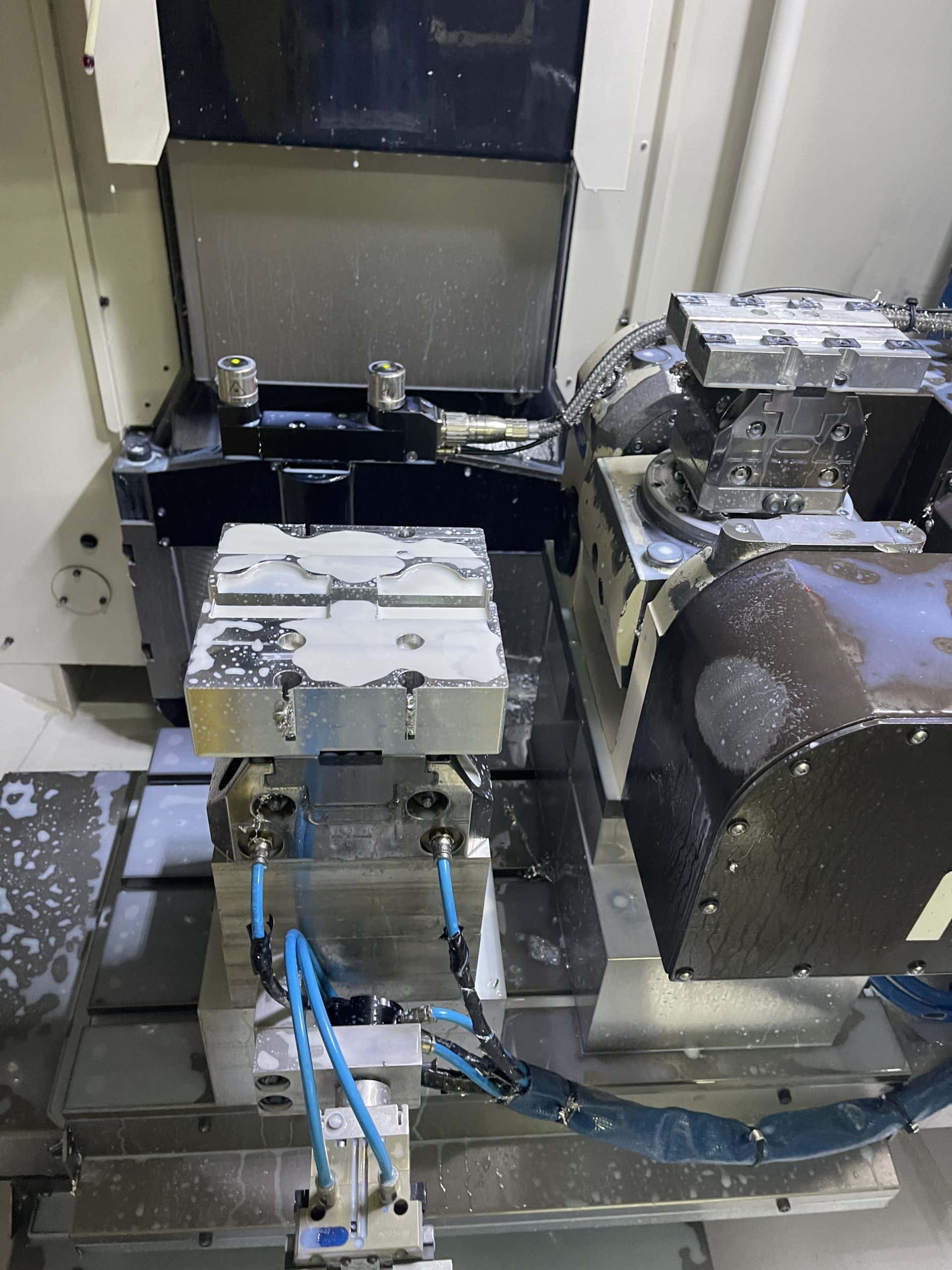

Tsudakoma TWA-130 4th and 5th Axis Rotary Table

Column Riser

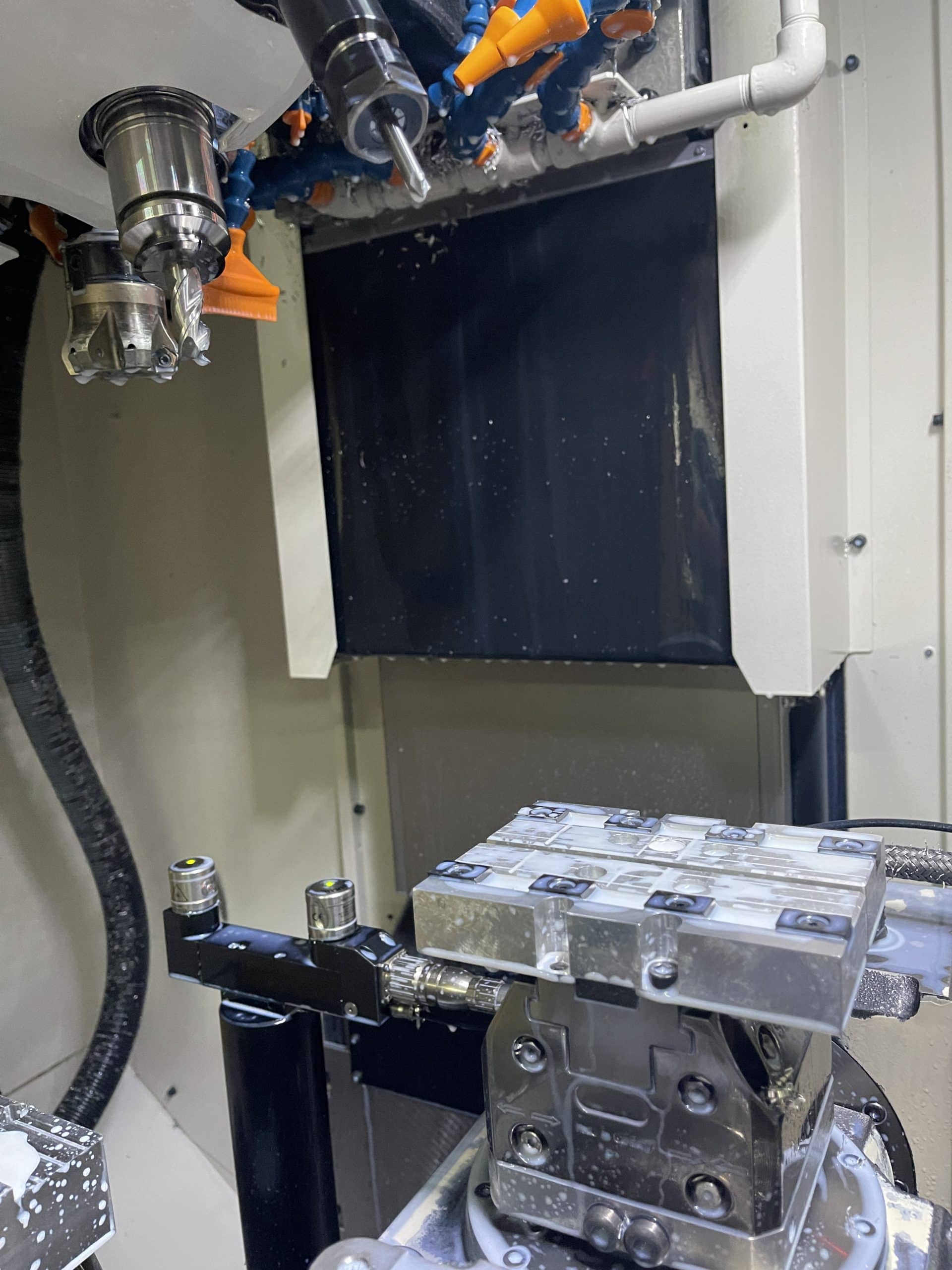

CTS High pressure coolant thru spindle 1000 PSI (adjustable)

Fanuc Robodrill High Speed package B, High speed

Jerk Control 31iB5

High Speed Process 31iB5

1000 Block Lookahead 31iB5

Rotary Table Dynamic Fix Offset 3IiB5

Tool Center Point Control 5Axis 31iB5

3D Cutter Comp 31iB5

Tilted Working Plane Command 31iB5

Ethernet Funct 31iB5

Data Server Function 31iB5 Fast Ethernet/Dataserver 4GB 31iB5

LNS-Turbo Chip conveyor LH/RH Side Discharge

MicroHinge 500, 227 liter / 60 gallon tank & Vari-Speed

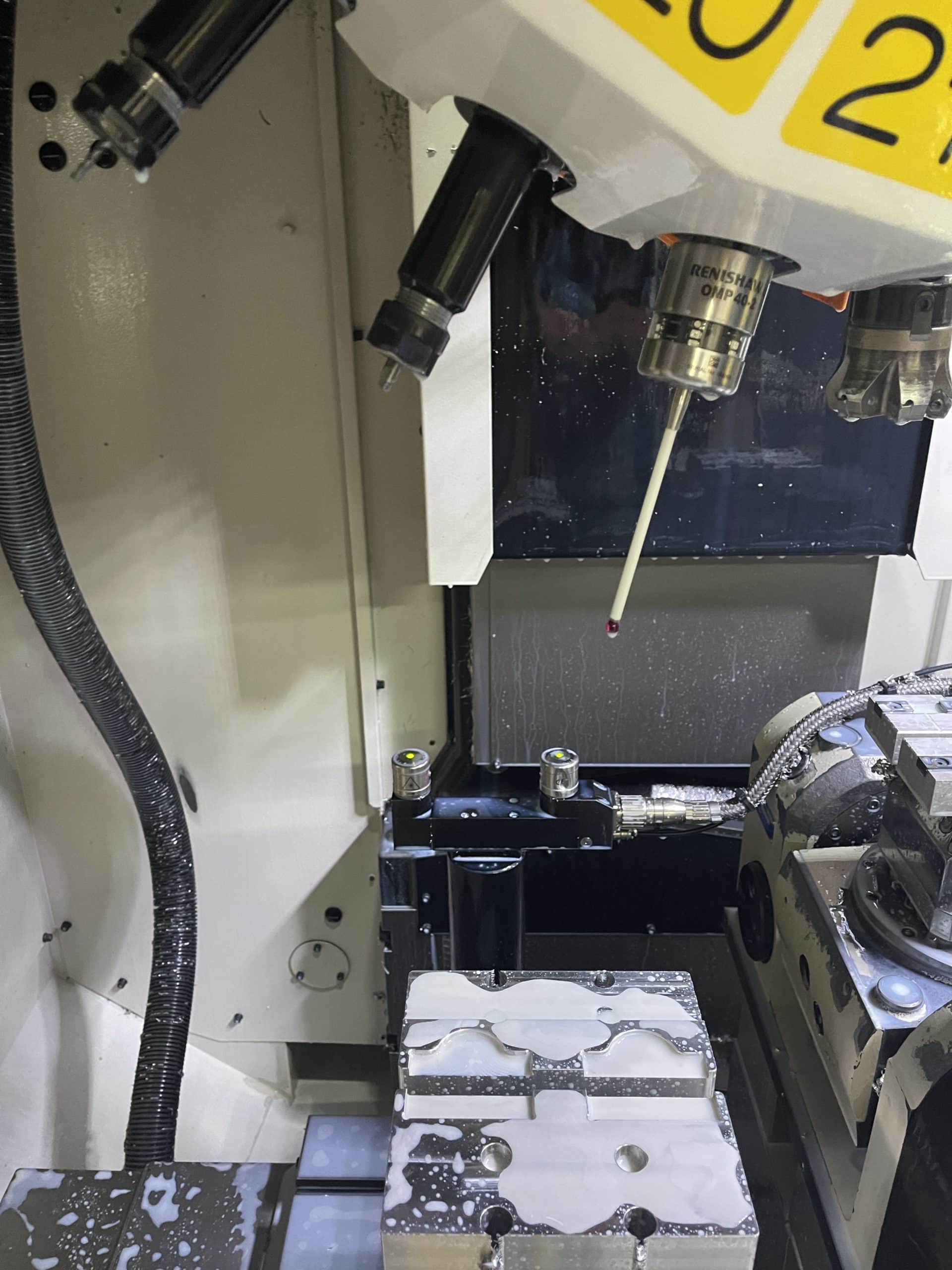

Renishaw OMP 40 In Process Measurement Optical Probe

Renishaw NC4 Laser Tool Setter & Broken Tool Detection.

Standard Features

Axis Travel of 19.68″ (X Axis), 15.74″ (Y Axis), and 12.9″ (Z Axis)

25.6” X 15.74” Table Area With A 660 Lbs Load Capacity

200-24,000 RPM Direct Drive High Torque Spindle

200L Coolant Tank

Optional Fully Integrated 4th Axis and 5th Axis

BT-30 Spindle Taper with “Big Plus” Dual Contact Spindle (four bearing design)

21 Position, Bi-Directional Tool Changer (New Design)

“Quick” ATC Recovery System

1.6 Second Tool Change Time (Chip to Chip)

0.9 Second Tool Change Time (Tool to Tool)

5,000,000 Duty Cycle Time

Rigid Tapping up to 8,000 RPM

“Quick” Tap Recovery System

High Speed Reverse Tapping

Thread Milling

Helical and Linear Interpolation

1 Millisecond Servo Response Time

Custom PMC

Simultaneous ATC / Table Positioning

2125 IPM Rapid Rate – X, Y, Z Axis

Feed Rates to 1181 IPM X, Y, Z

Multi Step Skip

AI Contour Control I

Nano CNC System

Ultra Precise 32,000,000 Pulses/Rev encoders

1.5 G Acceleration

Thermal Growth Compensation

2 MB Memory

1,000 Registerable Programs

Smart Backlash Compensation

HRV3 Plus

Tool Compensation Memory C

Tool Offset Pairs 200 Pairs

Part Program Storage 2 MB

6 + 48 Work Offsets

Coordinate System Rotation (G68.G69)

Coordinate System Setting (G92)

Custom Macro B

Canned cycles for drilling (G73, G74, G81~G89/G80)

Manual Handle Feed

Coolant System- 200 liter coolant tank and Spindle Coolant Nozzle

Coolant & Chip Splash Guard

Skip Function (G31)

Background Editing

Dynamic Graphic Display

On Screen Display of Spindle ‘ RPM’ and ‘Load’ Meters including cutting time

count down

Basic Metal Top Cover

Leveling Bolts and Pads

Alpha Numeric Keyboard

Automatic Lubrication System

NEW! Perodic Maintenance Management

Quick Side (Operator Interface)