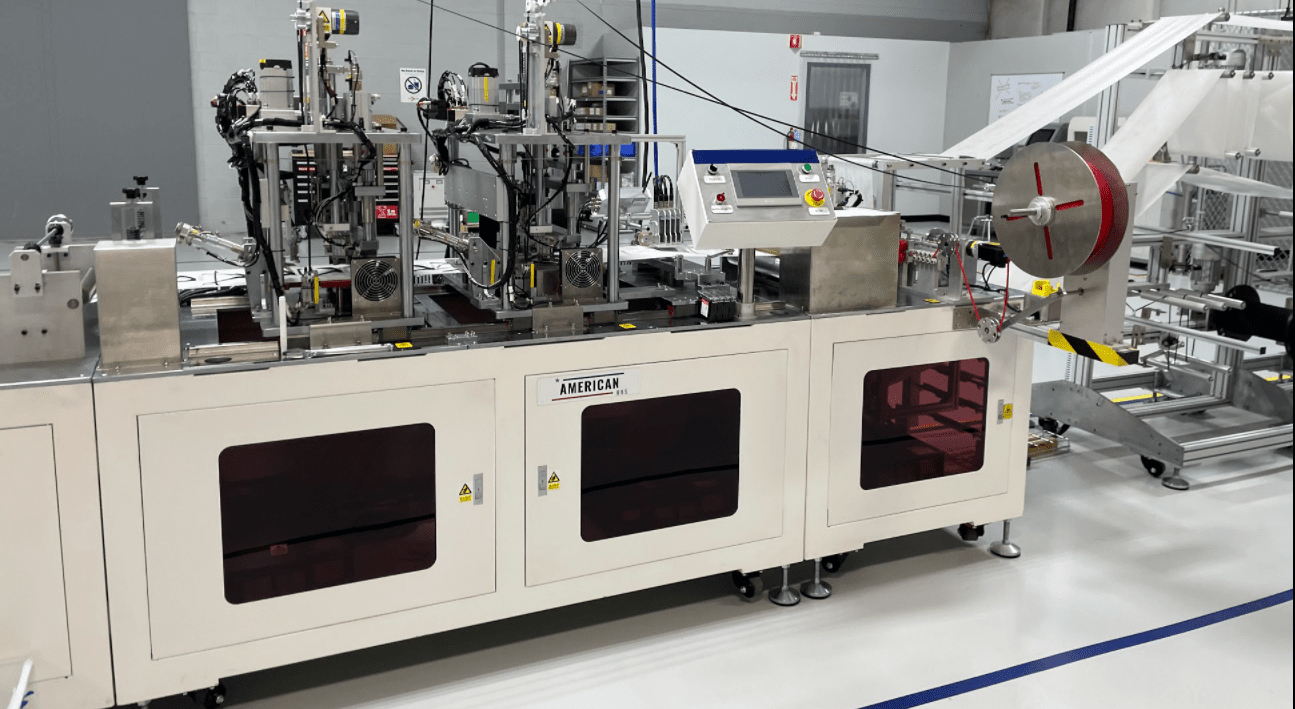

Full KN95 Mask Line, 2020- Comes with 200k mask worth of material, $80k in Spare Parts, Bagger Machine, Website, Packaging Logo/Design, BFE & PFE Certifications, Pass N95 requirements, Plug & Play Mask business

$127,500.00

This product is no longer available. For additional information, please fill out the form below.

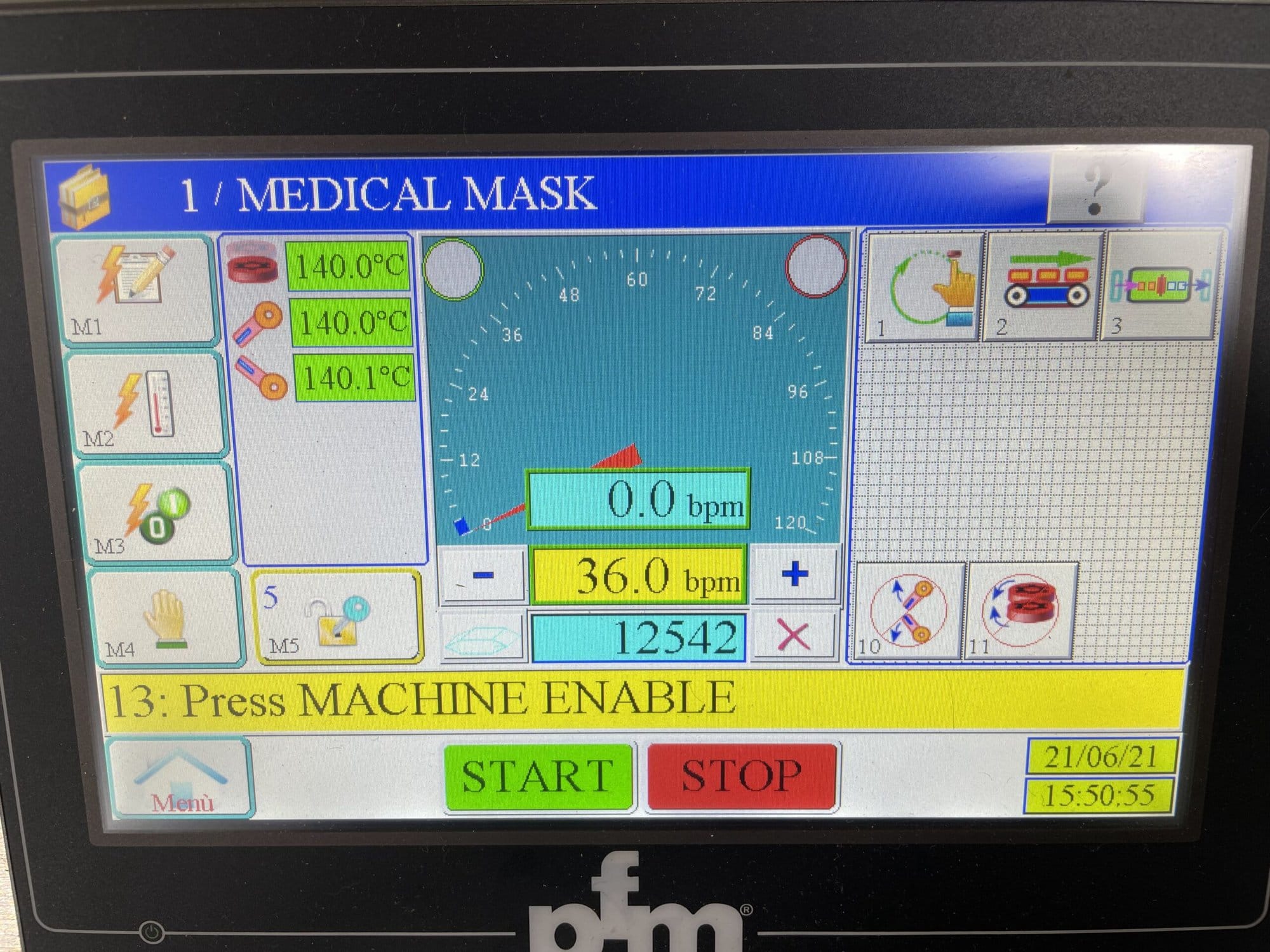

KN95 Flat Fold Mask Machine

-Extra Heavy Nose Bridge

-21 Masks a minute (1260/hr 10,000/shift)

-3-6 Filtration Layers

-24 Hour Customer Support

-Headbands (required for N95 Certification)

Includes;

-Mask Machine ($254K New)

-Materials (for up to 200,000 masks worth $30k)

-Spare Parts (worth over $80K)

-Website Domain

-Packaging Design

-BFE & PFE Certification Reports

-Bagger (55k New)

-Printer (ink for 1M mask, prints logos on mask)

-Omron Controls/PLC, Laptop and software license

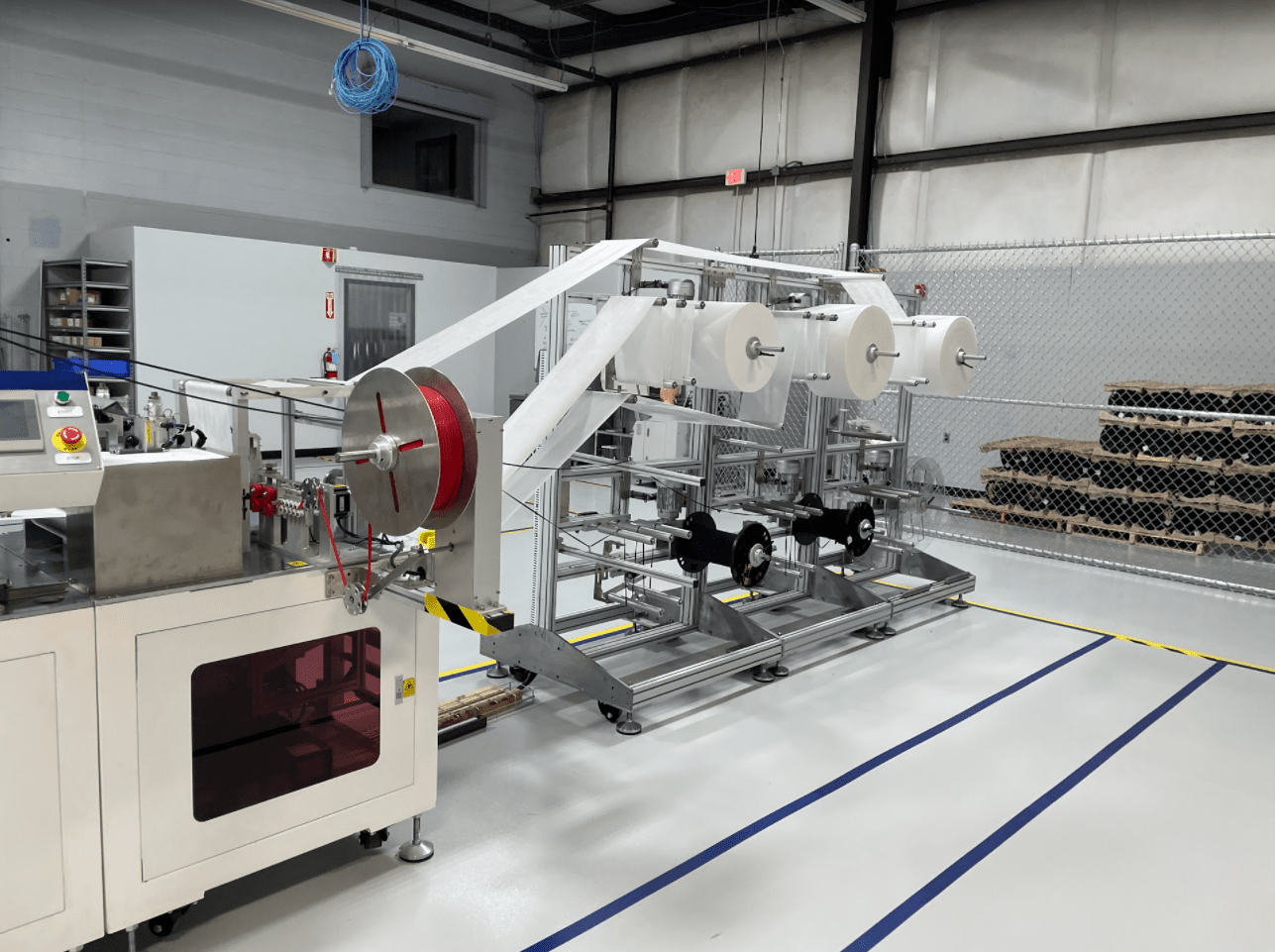

Station #1 Rollers-

up To Six Layers of Filtration Medium. We Used Three Layers and Used Two of The Automatic Reels for The Headband Material.

Station #2 Alignment-

Aligns up To 6 Layers of Filtration Material.

Station #3 Nose Bridge-

Feed, Cut, and Insert Nose Bridge

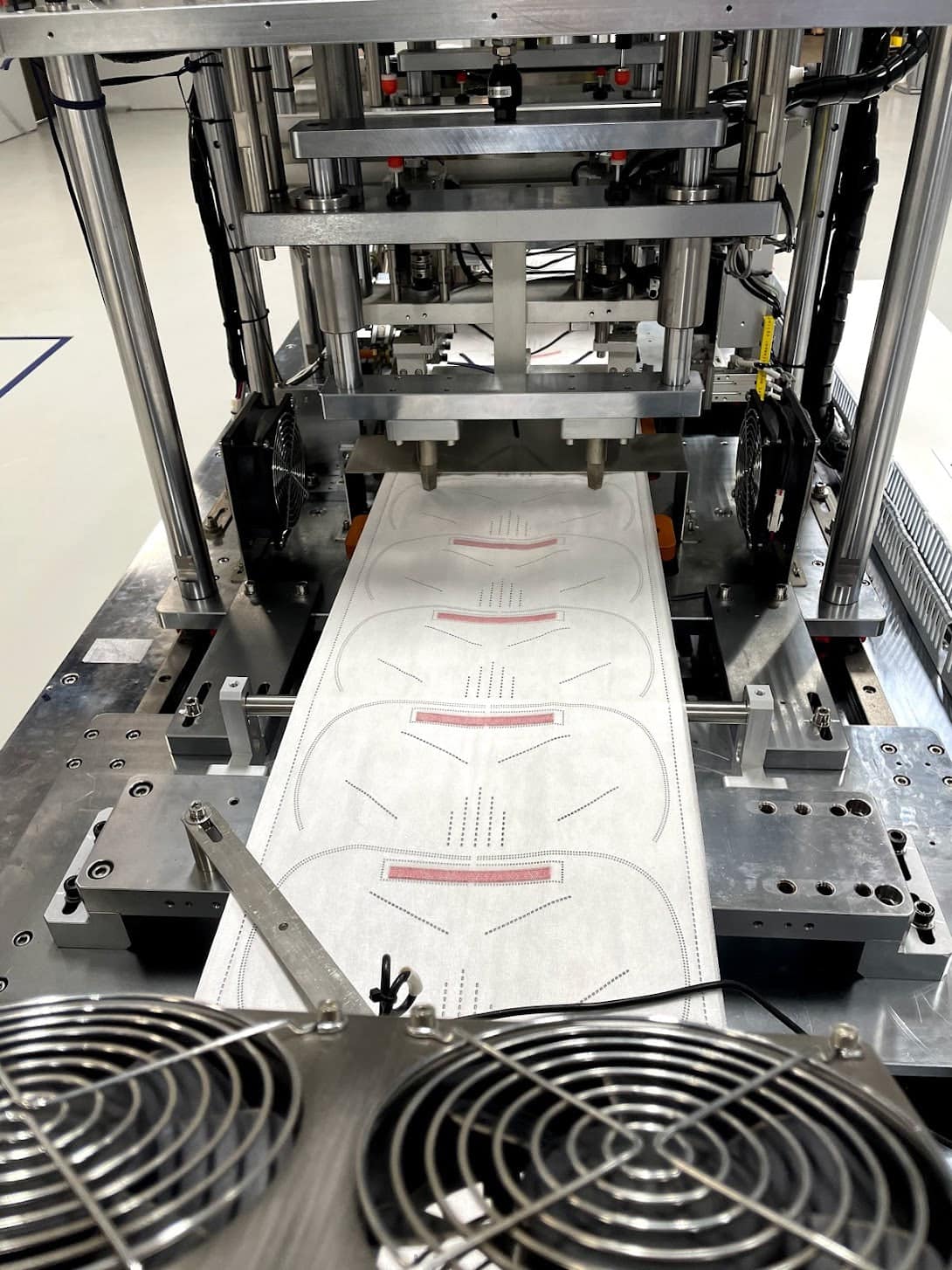

Station #4 Sonic Welding Roller-

This Station Welds up To 6 Filtration Layers Together with The Nose Bridge Between Layers 1 and 2.

Station #5 Printer-

4 Print Heads.

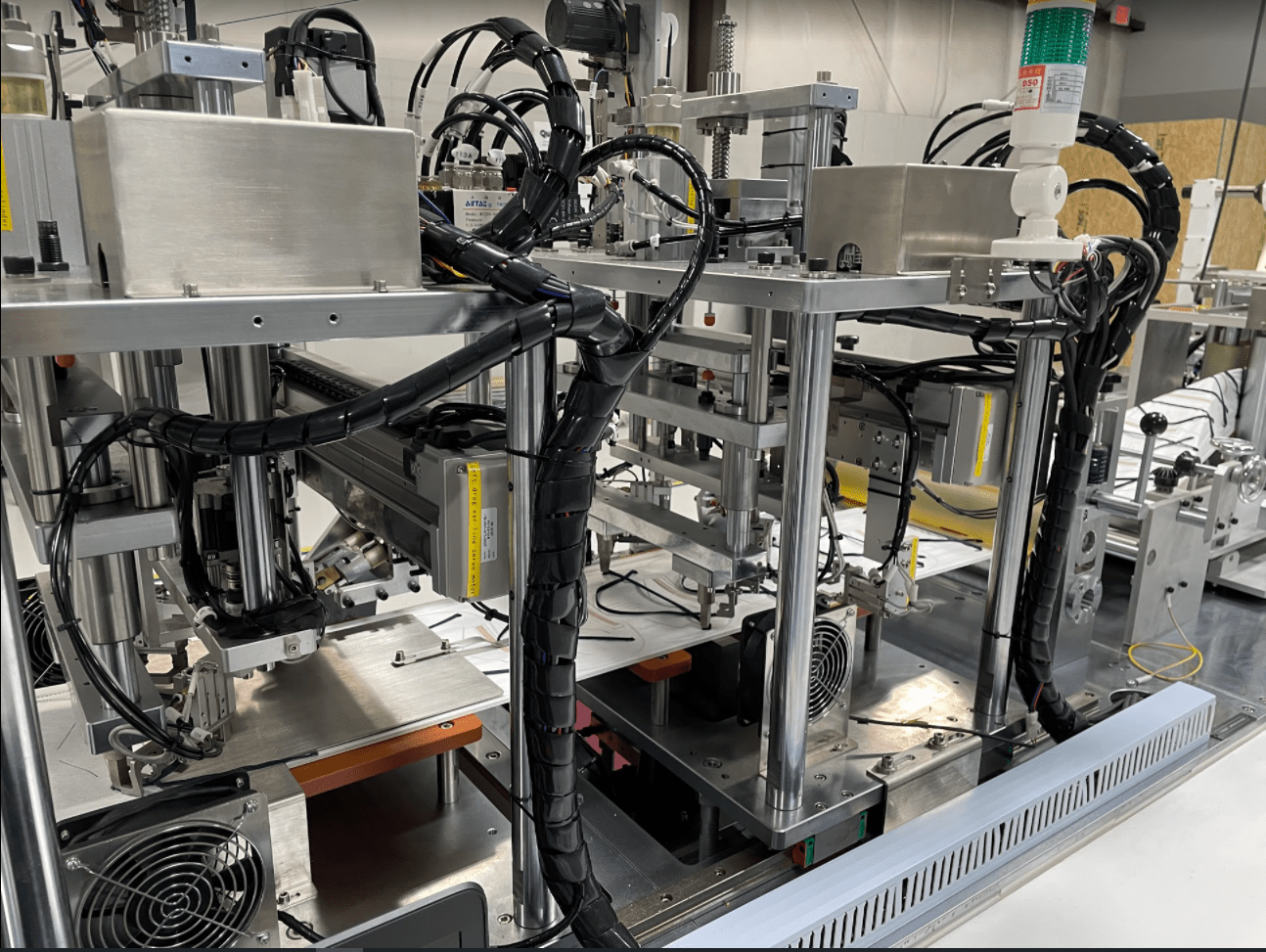

Station #6 Upper Head Band Installation-

Headband Material Is Fed Into the Machine, a Precise Linear Slide Pulls the Headband Material, Cutters

Cut the Headband to Length, Rotating Smc Grippers Place the Headbands Then Sonic Welders Lower and Weld the Headbands.

Station #7 Lower Headband Installation-

Same as Upper Headband

Station #8 Tensioner-

Sets the Alignment and Tension of The Mask Before Mask Folding.

Station #9 Mask Fold-

Rollers Fold the Mask in Half.

Station #10 Edge Seal-

Sonic Welding of The Front and Bottom of The Mask Edges.

Station #11 Head Band Lift-

Lifts the Headband so That It Is out Of the Way for The Cut-Out Station.

Station #12 Cut-Out-

Two Rollers Cut Around the Weld Lines of The Mask.

Station #13 Scrap Removal-

Separates the Mask from The Scrap.

Station #14 Bagger-

Bags Each Mask Individually.

Reported that the Manufacturer fully supports the unit.