Miller PerformArc PA-2200SS Robotic Welding Cell System, 2019

$119,900.00

This product is no longer available. For additional information, please fill out the form below.

Cell Construction:

Fully fabricated steel tubular frame with sheet metal wall structure

Framework is unitized; the main robot/positioner/controls section can be picked up from the front or back sides for placement and relocation

All cables are run in discrete paths or under deck plates or above entrance/exit points to prevent premature wear from welding spatter or contact with personnel

All lower cableways are covered with deckling to eliminate tripping hazards and protect the cables from the welding environment

One maintenance access door is included for easy robot maintenance

Robot riser with robot pre-assembled, dressed and mounted

Robot controller, welder and heavy power connections including transformers (if needed) are pre-wired and pre-assembled to run to a provided single electrical disconnect box at the rear of the work cell

System paint color of standard black

Fork lift access for easy transport

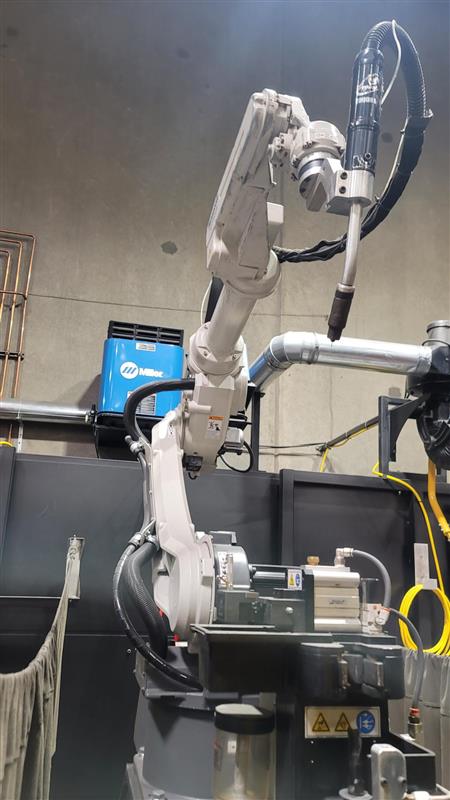

Robot: Panasonic TM-2000

Payload: 6kg

Inch reach to Point P : 79.2”

Controller: Panasonic G3

Panasonic G3 Teach Pendant (Windows CE 7″ Color GUI)

Automatic Program Backup – Standard

SD/USB ports – Standard

Collision Detection – Standard

Brake releases on arm – Standard

Second and Third Axis over travel switches, limiters, and electrical circuits – Standard

Servo Power On Lamps – Standard

TM can use a thru arm torch or a conventional over the arm torch design

Control: Panasonic G3 Series 64 bit RISC Windows CE Robot Controller

40,000 Point memory, virtually unlimited expansion with SD card

User I/O: 40 Inputs, 40 Outputs with optional expansion to 2,048 points

Single side access, low and high power available from front side

Faster and powerful CPU with half a minute boot-up time (50% faster than former model)

Ethernet LAN connection standard

Teach Pendant with 7-inch-wide TFT color LCD, Windows CE operation system

Three-position live-man switches

Jog-Dial for robot movement

+/- keys for absolute robot movement

Split screen windows, view program language and status window simultaneously

1 built-in SD card slot

LED back-light for rugged operation

Auto recognize TP software mismatch and download function

Lightweight, less than 1kg (2.2lbs)

Increased function keys from 4 to 5

Increased axis selection keys from 3 to 6

Cable connector at TP and Robot Controller

Customizable function keys

Standard Software features:

Choose your own program names

Tool Center Point Calibration Function

Cartesian, Articulated, Tool, Cylindrical, User and Tool Projection Coordinates

PTP, Linear, Circular, Weaving, Linear Weaving and Circular Weaving Interpolation

Parallel, RT Rotation, External Axis, Mirror, tool Pose Shift Functions

Resume Function for Power Interruption

Copy, Divide, Merge, Delete, Add, and Change Editing Function

Local and Global variables, including position variables

Automatic program backup software to supplied SD card

Password protection

Robot calibration function (software and hardware zero pins in robot arm)

Advanced error handling and recovery function

Off-line edit of running programs

Standard Welding Software Features:

Change-on-the-Fly Parameters through Teach Pendant

6 Weaving Patterns, Including Wrist Weave

Independent parameter control (per point basis)

Automatic Arc Re-try

Automatic Arc Overlap

Automatic Wire Stick Release

Automatic Wire Retract

Contact Tip Monitor via Arc-On Time or Running Time

Torch Angle Monitor

Weld Section Shifting

Optimum Kinematic calculation reducing air cut times by 10%

Cell Controls:

Heavy electrical power pre-wired and assembled, including common electrical disconnect

Light curtains in L-shape configuration at the front of the work cell

External axis brake release circuit and enabling box

Standard Panasonic cell controls

Start strip is mounted to the vertical tube to minimize opportunity to be damaged during production

Power Source:Auto Continuum 350 AMP Inverter Welder

350-Amp, 100% Duty-Cycle, Digital Welder

Inverter based Pulse Welding and CV Welding

80-Volt Touch Sensing Technology

Fan-on-Demand for lower power consumption and less shop noise

Auto Line Input = works on any voltage, any frequency

Miller Robotic Wire Feeder

Includes: Mounting bracket, wire drive, drive rolls, and digital interface

Torch: Tregaskiss Air Cooled Torch – Clamping Type

500 Amp Air cooled torch

Accurate and Durable gooseneck maintains a repeatable tool center point

The thick-walled aluminum gooseneck resists bending during collisions.

The sleek design improves accessibility into tight work zones

The hand nut makes maintenance easy -no tools required for neck replacement

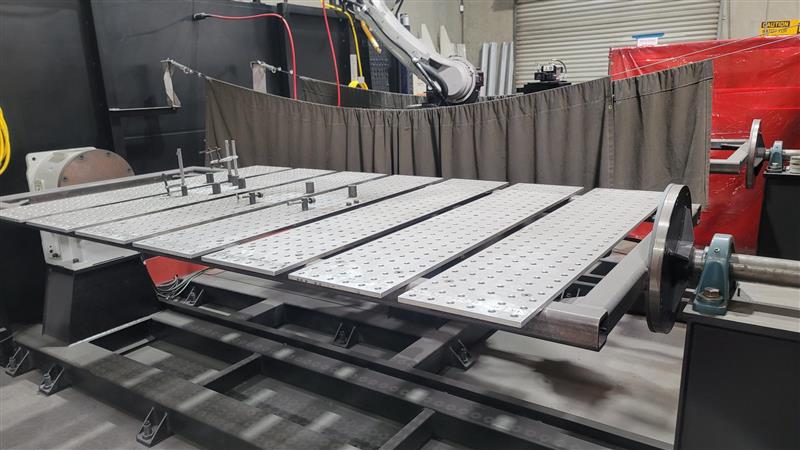

Positioners : 2 Stations, 1 Axis Per Station

Panasonic Servo Positioners (one per station)

2200-lb capacity per side

55mm through hole on outboard positioners for utilities passage

Headstock to tailstock length of ~120″

Rotation diameter of ~70″

All axis fully servo driven, not limited to indexed positions

Servo-disconnect technology to comply with latest safety standards. Removes power too outboard (operator side) servo when the light curtains are breached

Remote Jog Option Included

Equipped:

Panasonic G3 Series 64 bit RISC Windows CE Robot Controller

Auto Continous 350AMP Inverter Welder