Napasol Steam Pasteurization System, 2015

$1,700,000.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: Process Equipment

Make: Napasol

Model: Steam Pasteurization System

Year: 2015

Machine Location: Upon Request

Stock #: 769855

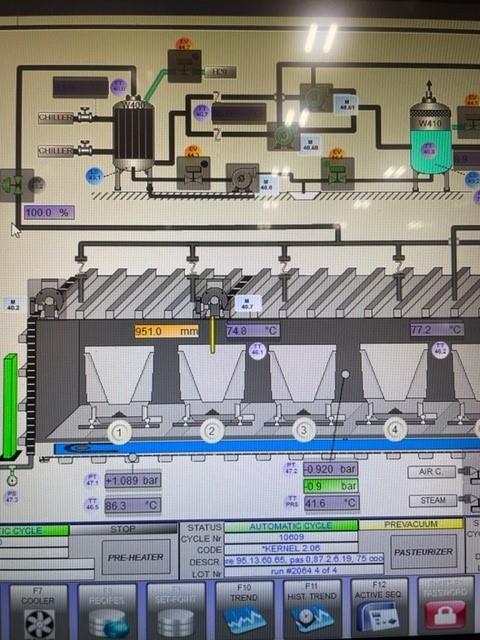

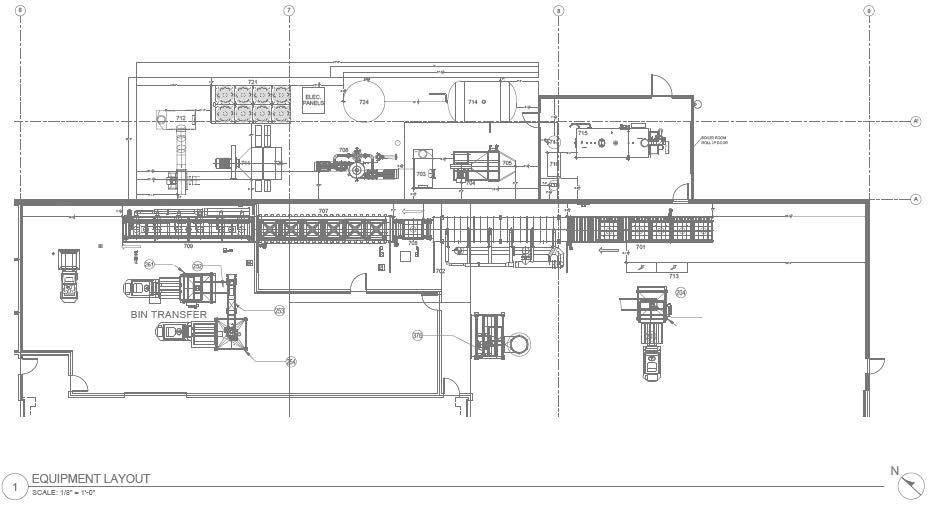

Napasol Steam Pasteurization system is a batch system manufactured by Napasol in 2015. It utilizes steam-heated hot air for preheating and a steam, pressure, and time pasteurization cycle in the autoclave chamber. The suggested configuration can be referred to in the drawing I’ve included. The control panel and distribution cabinet consist of a Rittal enclosure with four doors, high voltage distribution for motor drives, low voltage distribution, and a computerized automation HMI system. The automated process control software monitors the active process in all system areas, with the application displayed on the HMI display in the enclosure door. It offers various user login levels and supports both manual and automatic operation. The preheat stage chamber facilitates the hot air preheating of the product and has a capacity of 6 bins. It features an automatic vertical indexing temperature probe for process control and includes necessary hot air ducting, valves, and other components. Additionally, there is a steam heat exchanger and corresponding ducting and valves to conduct hot air into the preheat stage. The system also includes an infeed roller conveyor with both manual and automatic modes, equipped with light curtains used to count totes into the preheat stage. The conveyor is 20 feet long and 5 feet wide overall. The autoclave stage chamber, with a capacity of 6 bins, incorporates an automatic vertical indexing temperature probe for process control. It includes a steam valve, manifold, vacuum valve, and piping for steam removal. Roller conveyor decks are utilized to transport the product between stages. The cooling stage comprises a hood, roller conveyor deck, cooling air ducting, distribution valving, cooling fan, and drive motor. A cooling stage HEPA filter and cooling air supply fan are also included. The system incorporates a WAMGroup Filter of Type FPHTU54VS199600, manufactured in 2014, and a fan of Type GF900/4 with RPM 1765, KW 30, and operating at 460 VAC, 3 Ph. A cold water storage tank manufactured by Midwest Tank CO with Serial #20929 and ID #A68354A, built in 2014, is also part of the system. The chiller is a York model #YLAA0155SE46XTX with S/N 11531G42788289,manufactured on July 24, 2014. It operates at 115 V control voltage and 460 V, 3 Ph power, using refrigerant 410A in a 4-stage system. The chiller has an operating weight of 7267 lbs. The system also includes cold water pumps and piping. System has 24 bins.

All specifications are assumed to be correct but must be confirmed by the purchasing entity.