Okuma Multus B550-W CNC Lathe, 2016 – Big Bore, Installed 2018, Renishaw Probing

$689,900.00

This specific product is no longer available, however we may have other similar or identical products in stock. Please utilize our search function at the top of the page to check and confirm, or fill out the form below:

Control: Osp-P300s-H Cnc Control

Max Machining Diameter: 32.68″

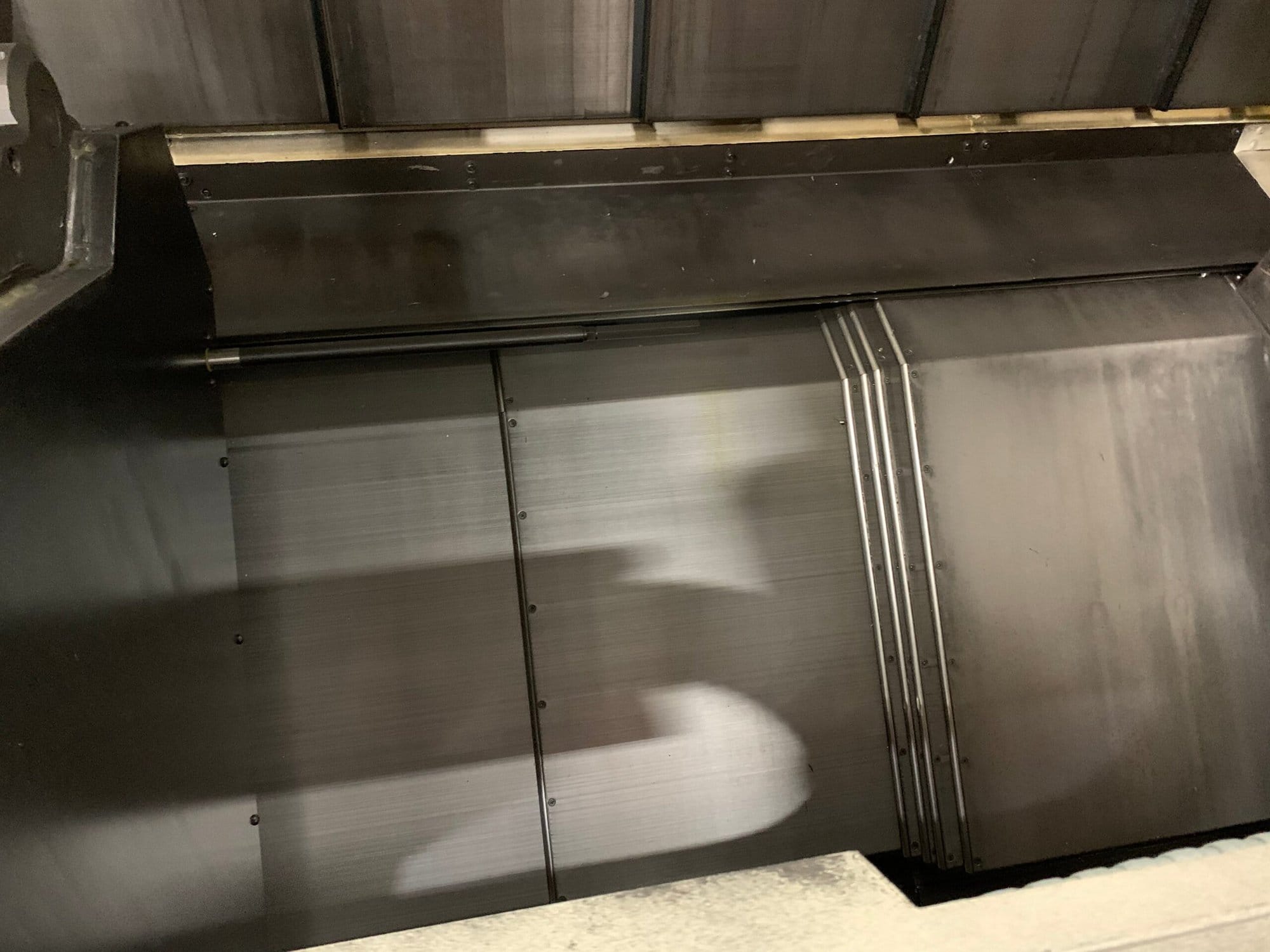

Max Center Distance: 118.11″ (3000mm)

X-Axis Travel: 36.42″

Z-Axis Travel: 126.57″

Y-Axis Travel: 20.47″

W-Axis Travel (sub Spindle): 122.05″

B-Axis Head Swivel: -30° / +210°

B-Axis Tilt Resolution: 0.001° Resolution

Full C-Axis Programmable Main And Sub Spindle

Live Milling Spindle Speeds: 40-10,000 Rpm

Tool Changer Capacity: 80 Stations

Milling Tool Holder: Capto-C8

Live Milling Drive: 50/40/30 Hp

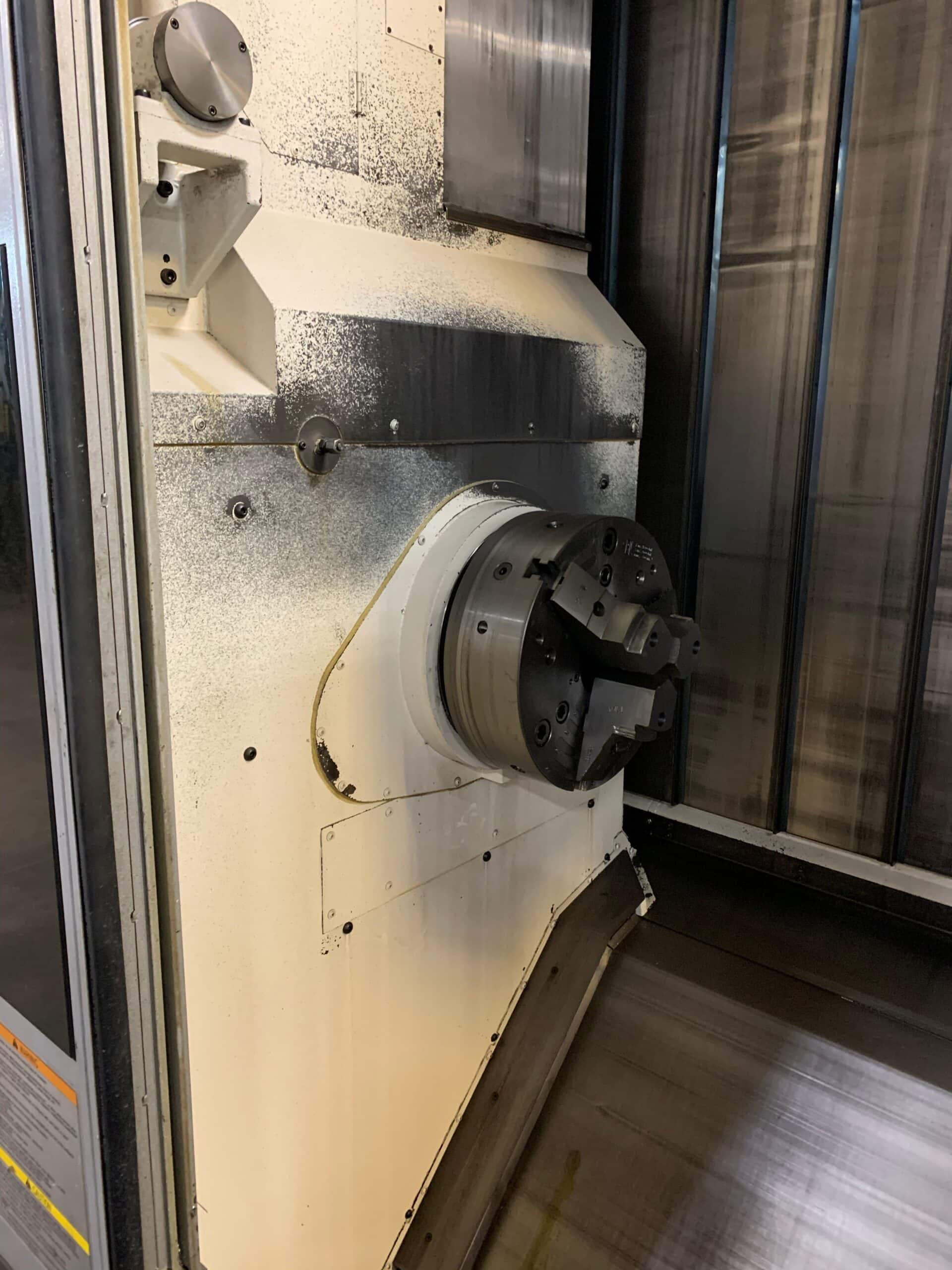

Workholding (left & Right Spindles): Schunk Rota Thw 400-120 15″ 3-Jaw Chucks With 4.72″ Spindle Hole

Turning Spindle Speeds: 24-2400 Rpm

Turning Spindle Nose: Jis A2-11

Turning Spindle Drive: 50/40 Hp

Turning Spindle Bar Capacity Left Spindle Only: Kitagawa F2511h 4.625″ Inner Diameter

Left And Right Spindle Inner Diamter: 5.12″ Spindle Id

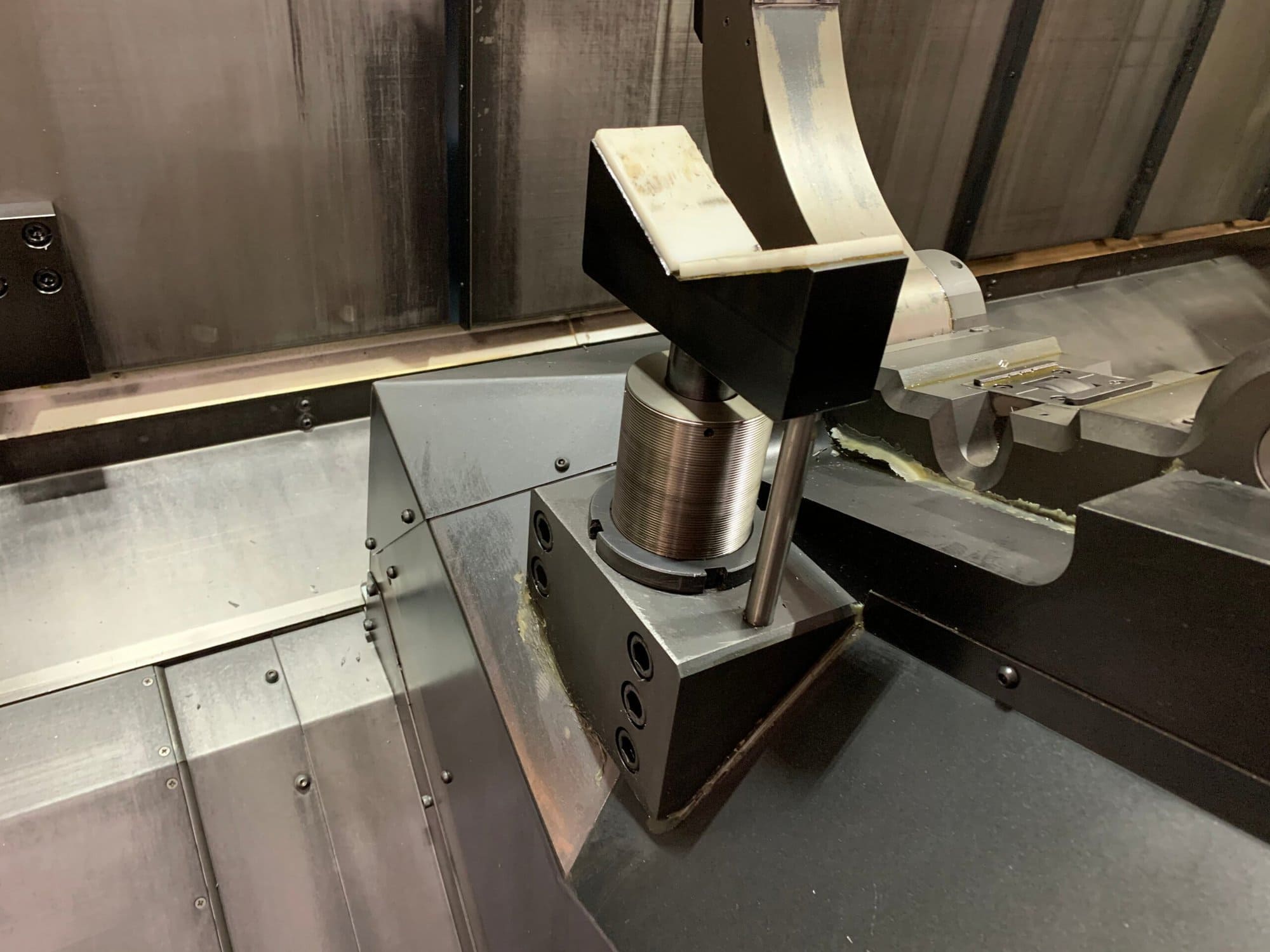

Programmable Steady Rest: Lns Model Slux-Z-5.1 3.35″ To 13.78″ Capacity

Rapid Traverse Rates: (x, Y, Z) – 1574.8 Ipm (w ) – 590.5 Ipm (c) 200 Rev/min (b) 30 Rev/min

Equipped With:

Okuma Osp-P300s-H Cnc Control

3000mm Between Centers Option

Dual Big Bore

50hp

2400rpm Left And Right Spindles With Full C-Axis And Sub Micron Control,

Dual Schunk Rota Thw (15″) 400-120 3-Jaw Chucks

10,000 Rpm

50hp Capto-C8 B-Axis Milling Head With 80 Station Tool Changer Option

Renishaw Auto Gauging Rmp 60 Parts Probing Kit

Automatic Tool Touchsetter

Smw Slux-Z-5.1 Programmable Steady Rest

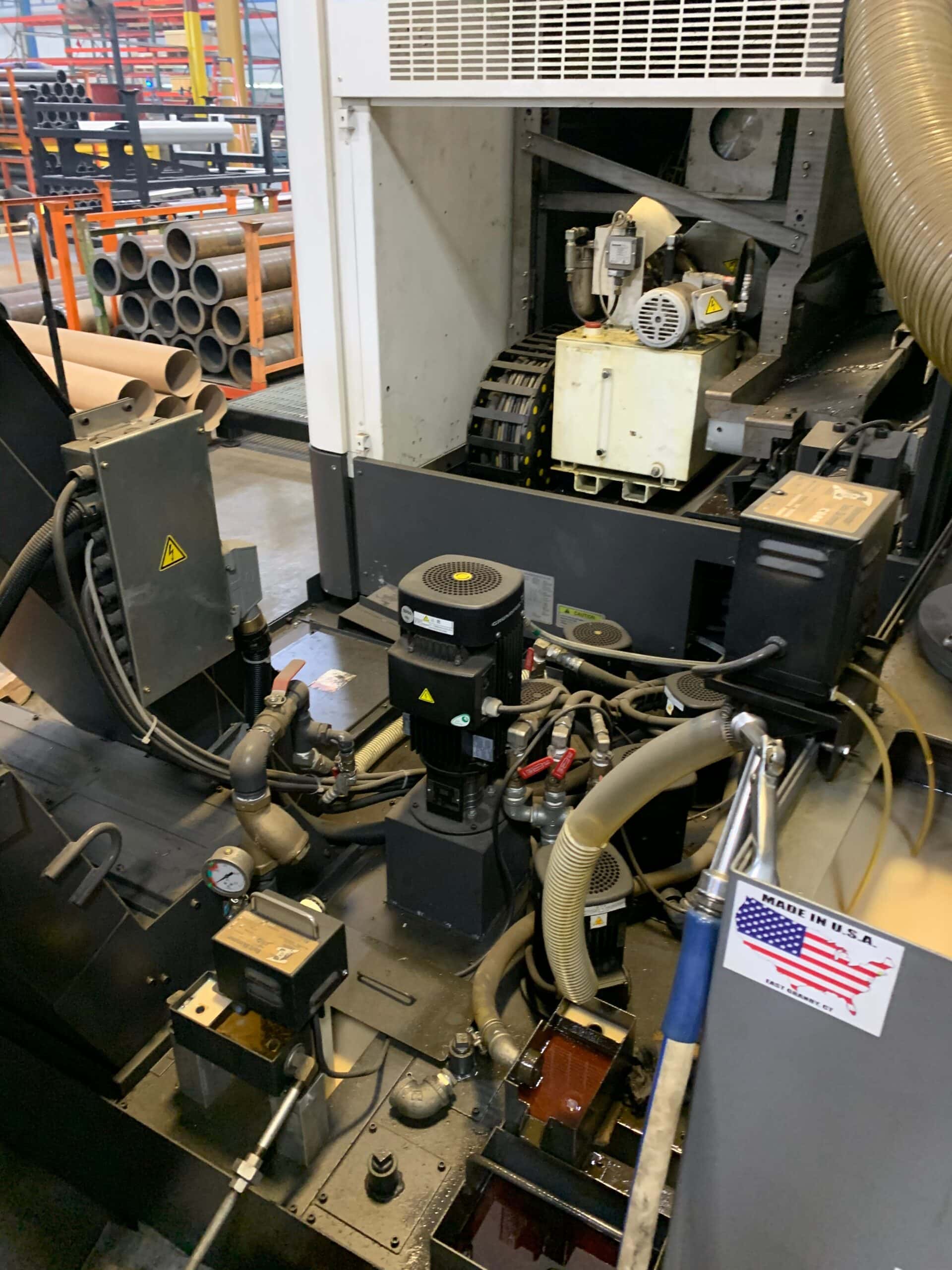

Mp Systems Vr8 1000 Psi High Pressure Coolant System

Mp1200 Mist Collector

Drum Filter Chip Conveyor System

Multiple Daikin Inverter Chillers

Control Options:

Gear Cutting Software Package

Okuma Osp-Suite

Tas-C Thermo Active Construction Stabilization

Tas-S Thermo Active Spindle Stabilization

Slope Machining B-Axis Function

Okuma Collision Avoidance System

Torque Skip Load Sensing Function

Pitch Error Compensation X+z Axis

Machine Manuals