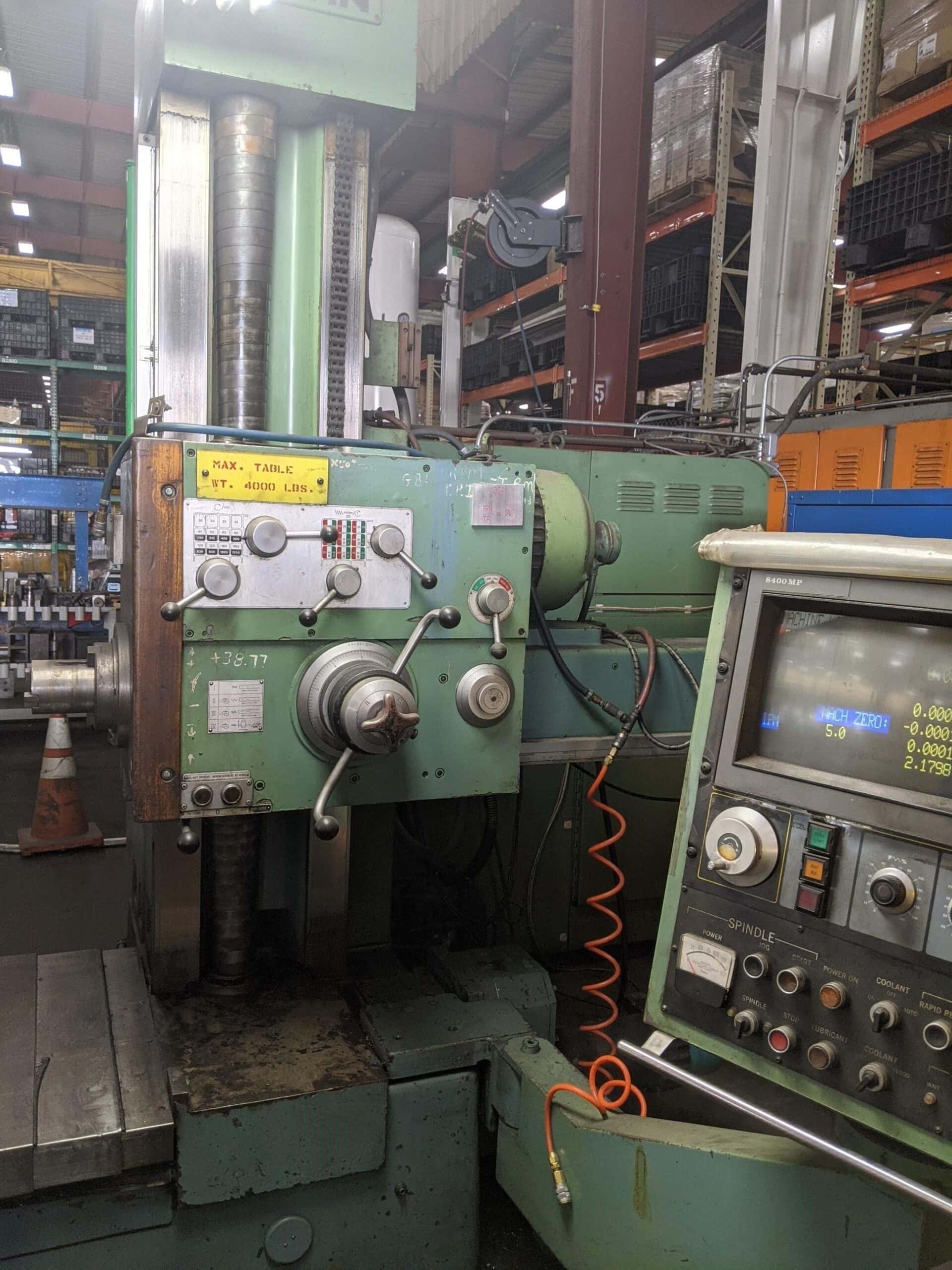

Wotan B75/105MNC NC Boring Mill, 1980s

$19,499.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: Boring Mills

Make: Wotan

Model: B75/105 MNC

Year: 1980

Machine Location: California

Stock #: 251996

50 taper in spindle, diameter 4”

Table size: 36” x 39”

Capacity: 4,000 pound

Allen Bradley controls, small memory, need to drip feed programs if you are doing surfacing work.

X travel: 52”

Y travel: 38”

Z travel: 31”

U travel: 360 degrees continuously

Spindle travel: 20”

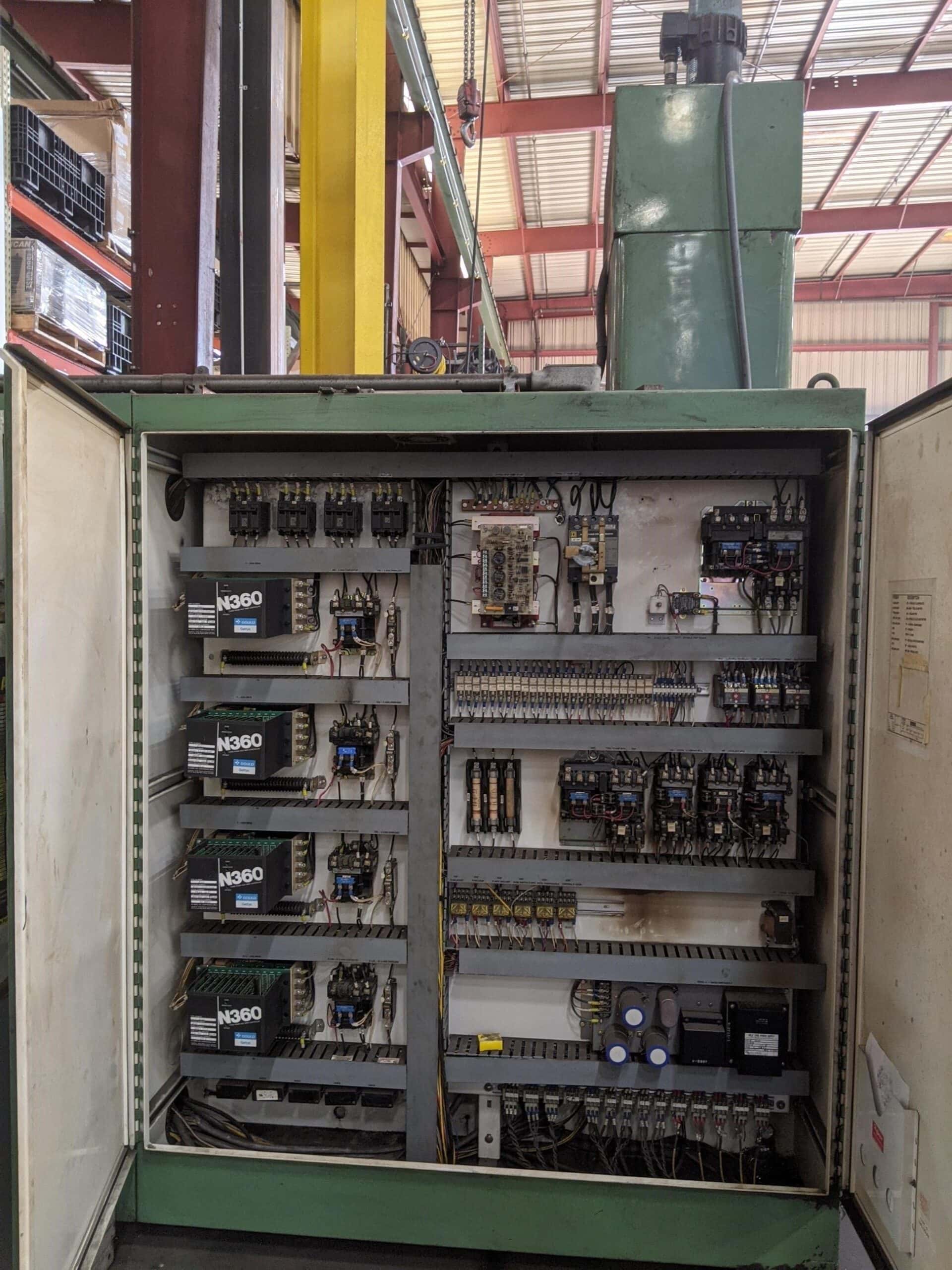

480 VAC 3 phase only

Approx Floor Space: 12′ x 9′ x 10′ tall

Approx Weight: 20,000 lbs

EQUIPPED WITH:

Allen Bradley 8400MP Control

Ball screw drives

This machine uses Heidenhain glass scales for position. Machine is accurate within a few thousands in X, Y, and Z axis. Ball screw backlash is not an issue with the machine relying on the DRO for position.

Note:

The machine has a problem with the memory- if machine is turned off completely, part program memory is not retained.

Desktop computer is used to load and save programs (RS232) for memory.

Spindle is mechanical. Currently power feed on spindle is not working. The motor is working, the problem is in the control circuit for the feed.

U axis only repeats within .015” over 36” of X axis travel. If you are running parts needing to be rotated with high precision, you need to use an indicator to “ZERO” the table each time.

Machine comes with approximately 30 to 40 tool holders, and a custom made spindle support when milling with the spindle extended. I could also include a aluminum tomb stone block if the buyer wants it.

It’s a great German engineered machine to last a long time.

All specifications are assumed to be correct but must be confirmed by the purchasing entity.