CMMs

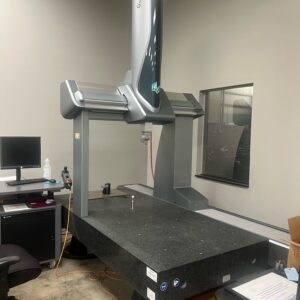

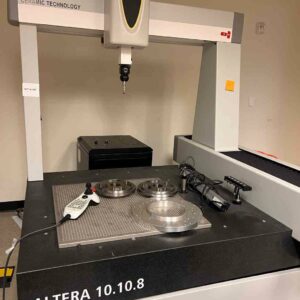

Used CMMs For Sale

Please view the regularly updated inventory of used CMMs below. Brands of used Coordinate Measuring Machines (CMMs) we sell include Brown & Sharpe, Mitutoyo, and more.

Revelation Machinery can always help you find what you need! If you have any questions about CMMs or need to find a specific brand/type, please feel free to contact us! Interested in selling your machinery? Sell your used CMM equipment to Revelation Machinery today!

Found Results

Coordinate measuring machines, also called CMMs are versatile and highly precise measurement tools used in a wide range of industries where precision and accuracy are critical including automotive, aerospace, medical devices, manufacturing, defense, electronics, and research and development. Not only are CMM machines valuable tools for ensuring the quality and reliability of parts and assemblies, but they also help to improve efficiency and productivity in manufacturing and design processes.

Some of the main uses of CMM equipment include:

- Inspection and quality control

- Reverse Engineering

- Tool and Mold Making

- Prototyping

- Research and Development

CMM Measurements

CMM equipment is capable of measuring the dimensions and geometry of objects in three-dimensional space. Using a combination of hardware and software to capture and analyze measurements, CMMs can measure a wide range of dimensions and features with high accuracy and precision. Some of the measurements CMM machinery has the capability to make include:

- Length: Measures the length of objects, including straight lines and curved surfaces.

- Width: Measures the width of objects, including flat surfaces and round objects.

- Height: Measures the height of objects, including flat and curved surfaces.

- Diameter: Measures the diameter of round objects, including cones, cylinders, and spheres.

- Depth: Measures the depth of objects, including holes and recesses.

- Angles: Measures the angles between surfaces, including acute and obtuse angles.

- Position: Measures the position of features relative to a reference point or coordinate system.

- Surface: Measures the shape and profile of surfaces, including curvatures and roughness.

CMM Machine Types

There are several different types of coordinate measuring machines, each with its own strengths and weaknesses. The choice of CMM will depend on the specific application and requirements. The main types of CMM machinery include:

- Bridge CMMs – As the most common type of coordinate measuring machine, Bridge CMMs have a bridge-like structure that spans the measuring area. The probe is attached to a moving carriage that travels along the bridge to measure the part.

- Gantry CMMs – Similar to bridge CMMs, the bridge on Gantry CMMs is supported by vertical columns that move on a fixed base, allowing for a larger measuring volume and higher accuracy.

- Portable CMMs – Smaller and more lightweight, portable CMMs can be moved around the part being measured, making them useful for measuring parts that are too large or too difficult to move to a stationary CMM.

- Horizontal Arm CMMs – With a horizontal arm that extends over the part being measured, these are useful for measuring large, heaving parts that are difficult to move.

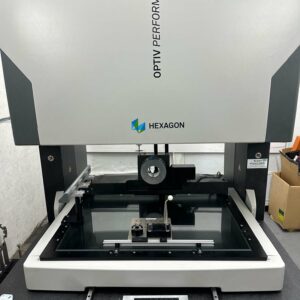

- Optical CMMs – Using optical sensors such as laser or vision systems, optical CMMs can measure parts without touching them which is ideal for delicate or complex parts.

- 3D Scanning CMMs – These use a probe with a 3D scanner to capture a point cloud of the part being measured. The point cloud can then be used to create a 3D model of the part.

- White Light CMMs – Using white light projection systems to measure parts, white light CMMs are ideal for measuring parts with complex geometries and fine details.

Just as there are different types, CMM machines are also known by various other names that reflect the diverse range of applications and technologies used in modern CMMs. Some CMMs use contact probes to measure dimensions, while others use non-contact methods such as laser scanning or vision systems. Some coordinate measuring machines are designed for portable use while others are large and stationary for use in manufacturing or research environments. Alternative names of CMMs include:

- Coordinate Measurement System or (CMS)

- Coordinate Inspection Machine or (CIM)

- Dimensional INspection Machine or (DIM)

- 3D Metrology System

- Precision Measuring Machine or (PMM)

- Inspection System

- Measuring System

- Articulated Arm CMM

- Laser Scanner CMM

- Vision Measurement System

Advantages of CMM Machines

High Precision – Provides high-accuracy measurements and can measure dimensions to a precision of a few micrometers.

Repeatable Measurements – The same part can be measured multiple times with consistent results which is important for quality control and ensures that parts are manufactured to the same specifications every time.

Speed – Multiple points on a part can be measured simultaneously which allows the data to be processed automatically, resulting in faster measurement times.

Large Measuring Range – Measures parts of various sizes and shapes, making CMMs a versatile tool in the manufacturing and design process.

Data Collection & Analysis – Can collect large amounts of data quickly, and accurately, including statistical analysis and graphical representation of measurement results, making it easier to identify trends and areas for improvement.

Non-Contact Measurement – Some coordinate measuring machines use non-contact measurement techniques, such as laser scanning, which is ideal for measuring delicate or soft parts without damaging them.

Quality Control with CMMs

Overall, CMMs are an essential tool in the manufacturing industry’s quality control process because they offer a highly accurate and precise method of measuring the dimensions and features of manufactured parts. This is critical for ensuring that the parts meet the design specifications and the required tolerances. Quality control is essential to ensure that the final product meets the customer’s requirements and expectations. Coordinate measuring machines achieve this by providing fast and accurate measurement data for each manufactured part. By using CMM equipment for quality control, manufacturers can identify any deviations from the design specifications and make the necessary adjustments to maintain product quality.

CMM machinery also offers the ability to measure a wide range of geometries, including complex shapes and contours which is essential for manufacturers that produce parts with intricate features like medical devices or aerospace components. Moreover, CMMs offer a non-destructive and non-contact method of measurement, which is extremely useful for measuring delicate or fragile parts that cannot be measured with traditional measurement tools.

Factors to Consider When Buying a Used CMM Machine

There are several important factors that should be considered when purchasing a used CMM machine to ensure it meets the specific needs and requirements of the applications. Key factors include:

- Accuracy

- Measuring Volume

- Probe Options

- Software

- Speed

- Support and Maintenance

- Budget

Revelation Machinery can always help you find what you need! If you have any questions about used CMM machines or need to find a specific brand or type, please contact us. Interested in selling your equipment? Learn how you can get cash fast when you sell your used coordinate measuring machines to Revelation Machinery.