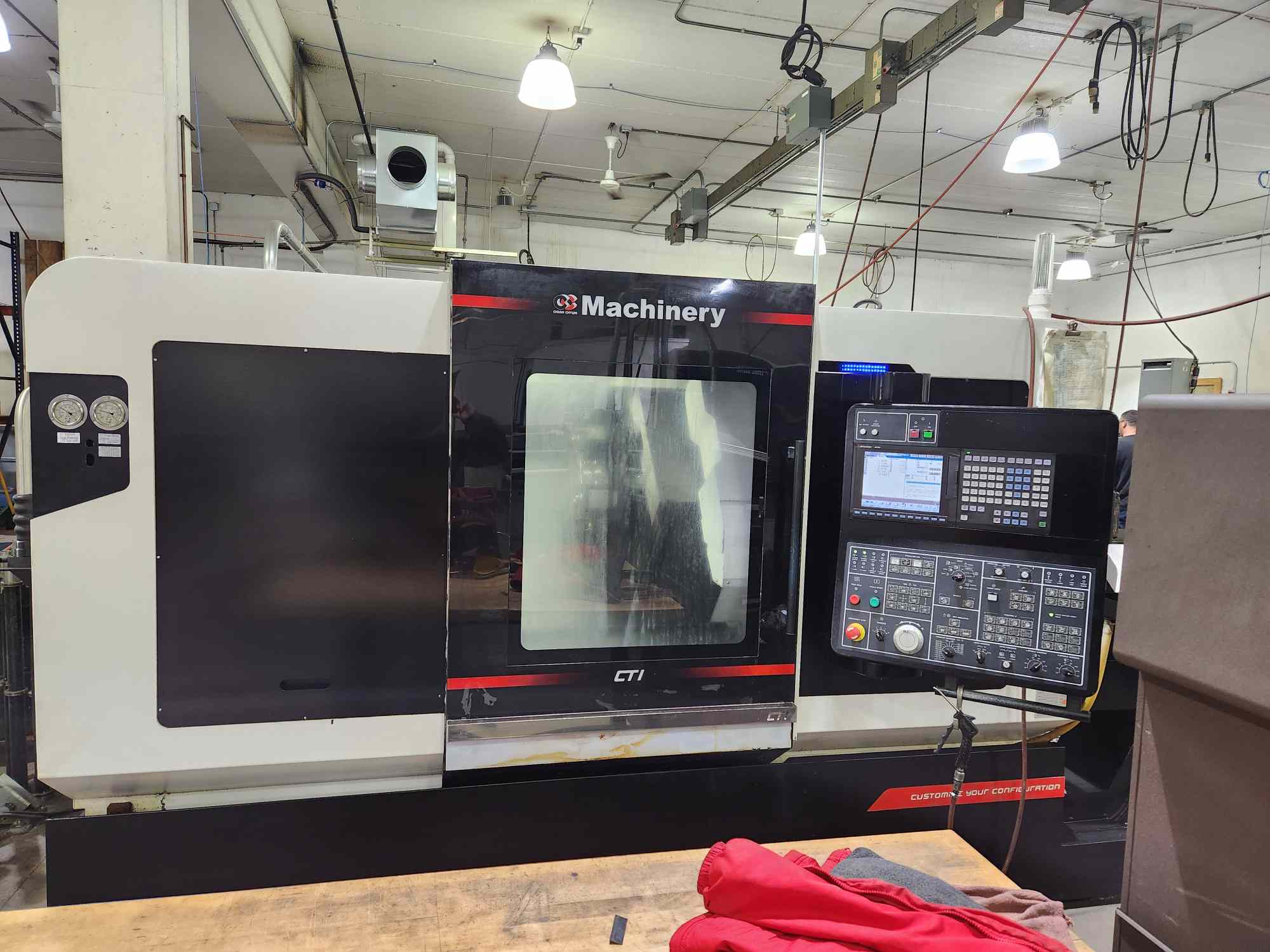

Ganesh Cyclone 78 MSY Lathe, 2015 – Edge technologies Rebel 102, Live Tool Holders, Parts Conveyor

$69,900.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: Multi Axis Lathes

Make: Ganesh

Model: 78-MSY

Year: 2015

Machine Location: Upon Request

Stock #: 441849

CAPACITY –

Turning Diameter Maximum: 12.2″ (310 mm) / O8.2″ (210 mm)

Center Distance 41.7″ (1061mm)

Turning Length 24.8″ (630mm) maximum

MAIN SPINDLE – Integral Spindle

Spindle nose / bearing diameter ASA Size A2-6 / 4.72″ (120mm)

Spindle Bar Cap: 3.070″ (78 mm drawtube I.D. /

88mm / 3.465″ spindle bore

Chuck Size 10″ (with 78mm bore)

Spindle Center Height 40″ (1,000mm)

Spindle speed 60 – 4,000 RPM

(Integral Refrigerated Spindle)

Spindle motor power 15/22Kw Hp/ 30-HP (30-minute

rating) / 20-HP (Cont)

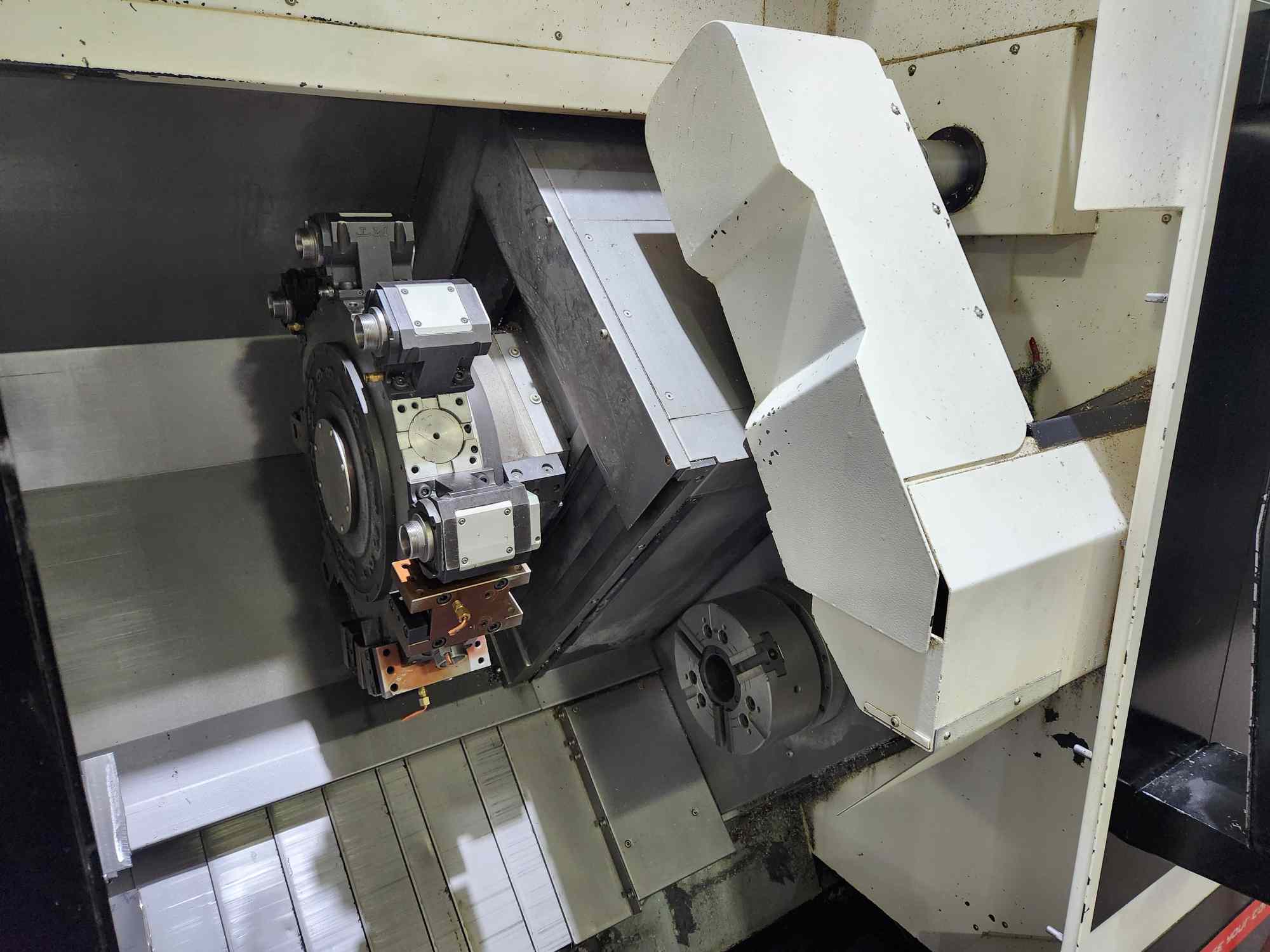

SUB SPINDLE – Integral Spindle

Spindle nose ASA Size A2-6

Spindle Bar Capacity 2.559″ (65 mm drawtube I.D. /

86mm / 3.386″ spindle bore)

Chuck Size 8″ (w/ 65mm bore) (10″ optional)

Spindle speed: 60 – 4,000 RPM (Integral Spindle)

Spindle motor power 11/15Kw Hp 15-HP (30-minute

rating / 10-HP (cont)

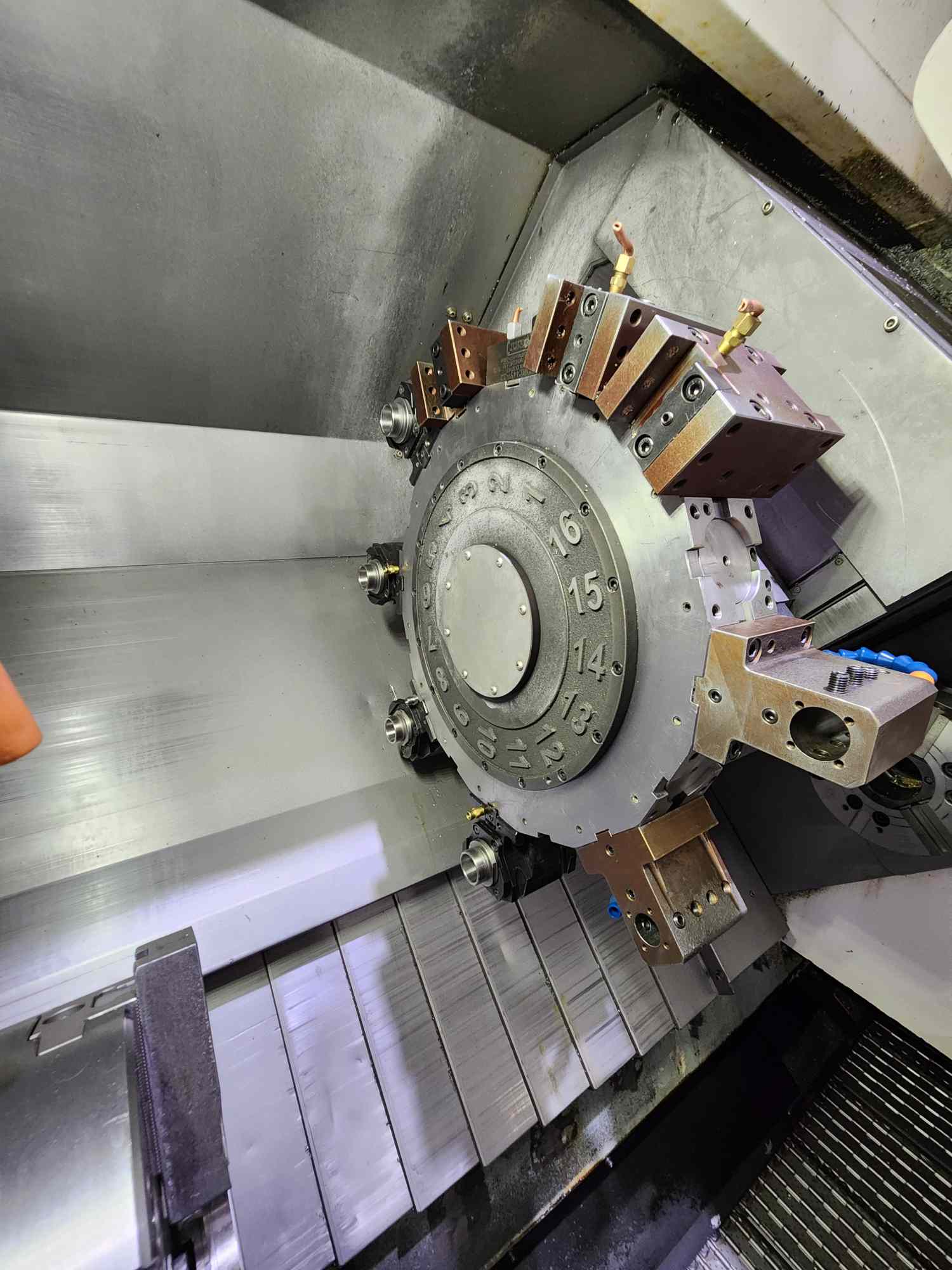

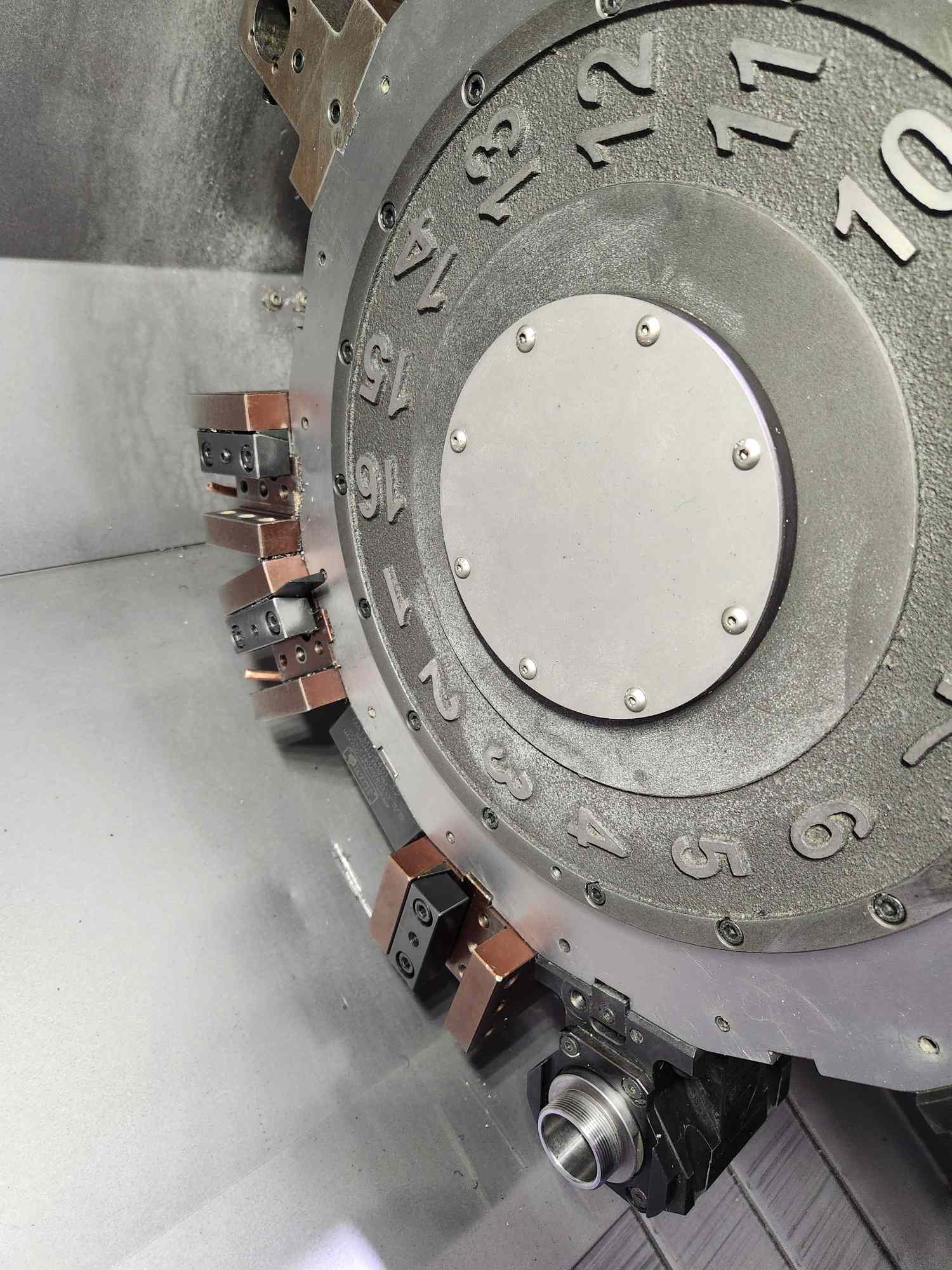

LIVE TOOL TURRET –

16-Station Servo Driven Live Tool Turrets

Number of turret stations 16

16 (Any combo of 16 ID, OD or

Live tool stations)

Index time, adj tool / 180 deg index 0.2 seconds / 1.2 seconds

High-Speed Servo Indexing

Live Tool Power / RPM: 3.7/5.5KW (7.5 HP) / 6,000 rpm

Tool Size / Collet Size 1″ (25mm) (for square tool &

32mm round tools) / ER-32 collets

Tool Holder Type & Size BMT-65 Base Mount Tooling

Turret Thru-The-Tool-Coolant Rated 1,000 PSI for High Pressure coolant

option

“C” AXIS – On both spindles

Spindle Radial Resolution / Speed 0.001; 360,000 radial positions

w/ full contouring cap / 600 RPM

“B” AXIS – (sub spindle travel)

B Axis Rapid Traverse 1,573 Inch Per Minute

(40m per minute)

B Axis Travel 29.31″ (744mm)

AXIS SPECIFICATIONS –

Axis Travel – X / Y / Z Axis X 9.05″

Y +/- 1.968″

Z 23.7″

Rapid Travers Rate – X / Y / Z Axis 630 / 236 / 1,574 ipm

(16 / 6 / 40 m/minute)

Axis Motor Power Horsepower 3-Hp in X, Y, Z axis

Axis Continuous Thrust Rating Pounds X = 2142, Y = 2924, Z = 1425 pounds

of thrust force

Minimum Programmable Input 0.0001″ (0.001mm = 40 millionths)

ANCILLARY SPECIFICATIONS-

Hydraulic System Gallons 8- gallons (30 Liters) with

5-HP (3.5kw) pump motor

Coolant Pumps – Dual Coolant Pumps 2 x 1.7 hp pumps for tooling

2 pumps for chip flushing

Coolant Tank Gallons 74-gallon (280 Liters) coolant tank

MACHINE WEIGHT 17,650lbs (8,000 kgs) –

Shipping Weight 18,680 lbs. (8472kgs)

ELECTRICAL REQUIREMENT – 56 KVA, 220vac 5%, 3-phase,

60 Hz, 130 amps

AIR REQUIREMENT – 85-psi @ 8-cfm for parts catcher

ejector, oil mist lubricator

MACHINE DIMENSIONS – 145″L / 82″D / 82″H

(Plus 44″ for chip conveyor)

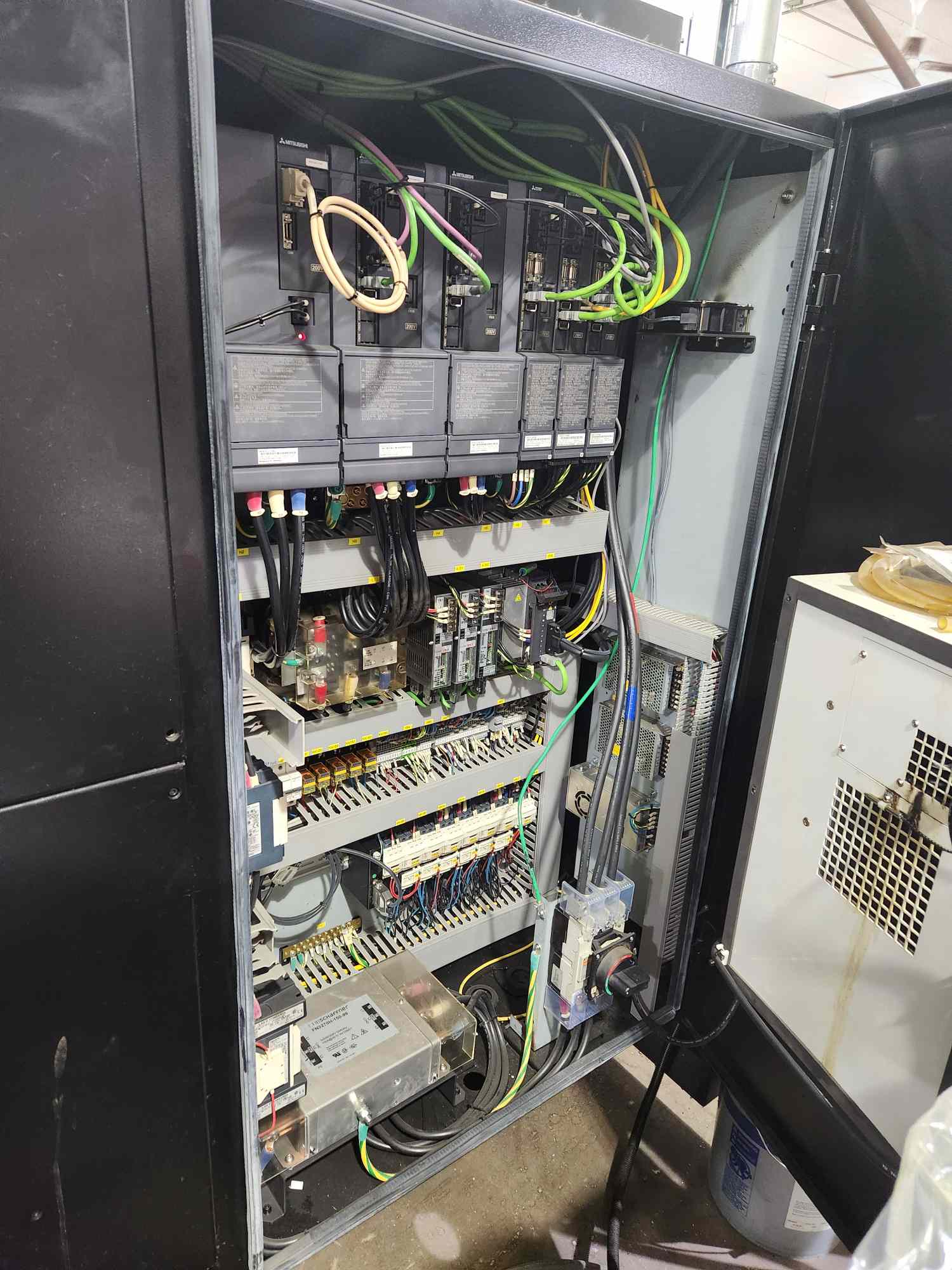

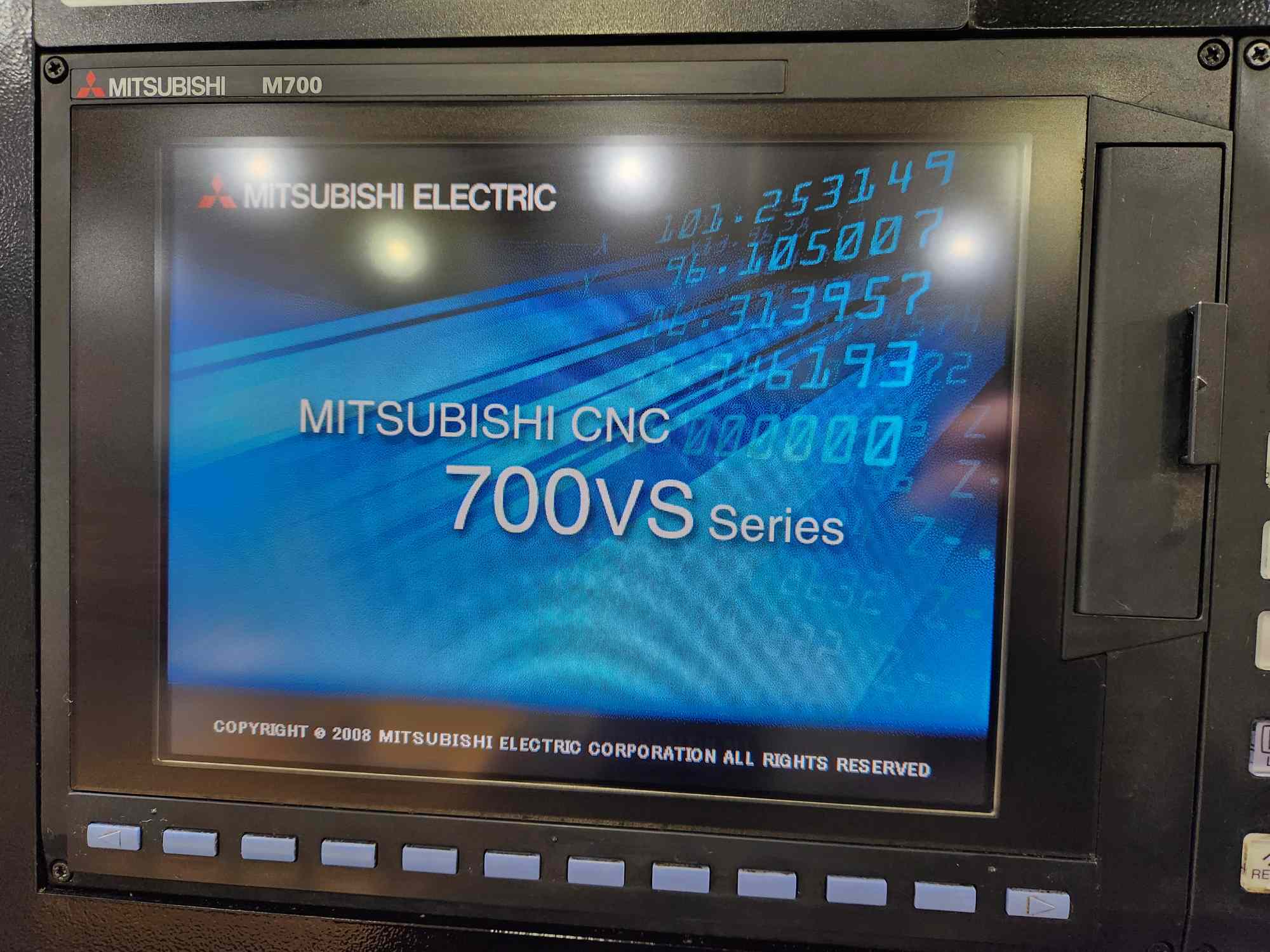

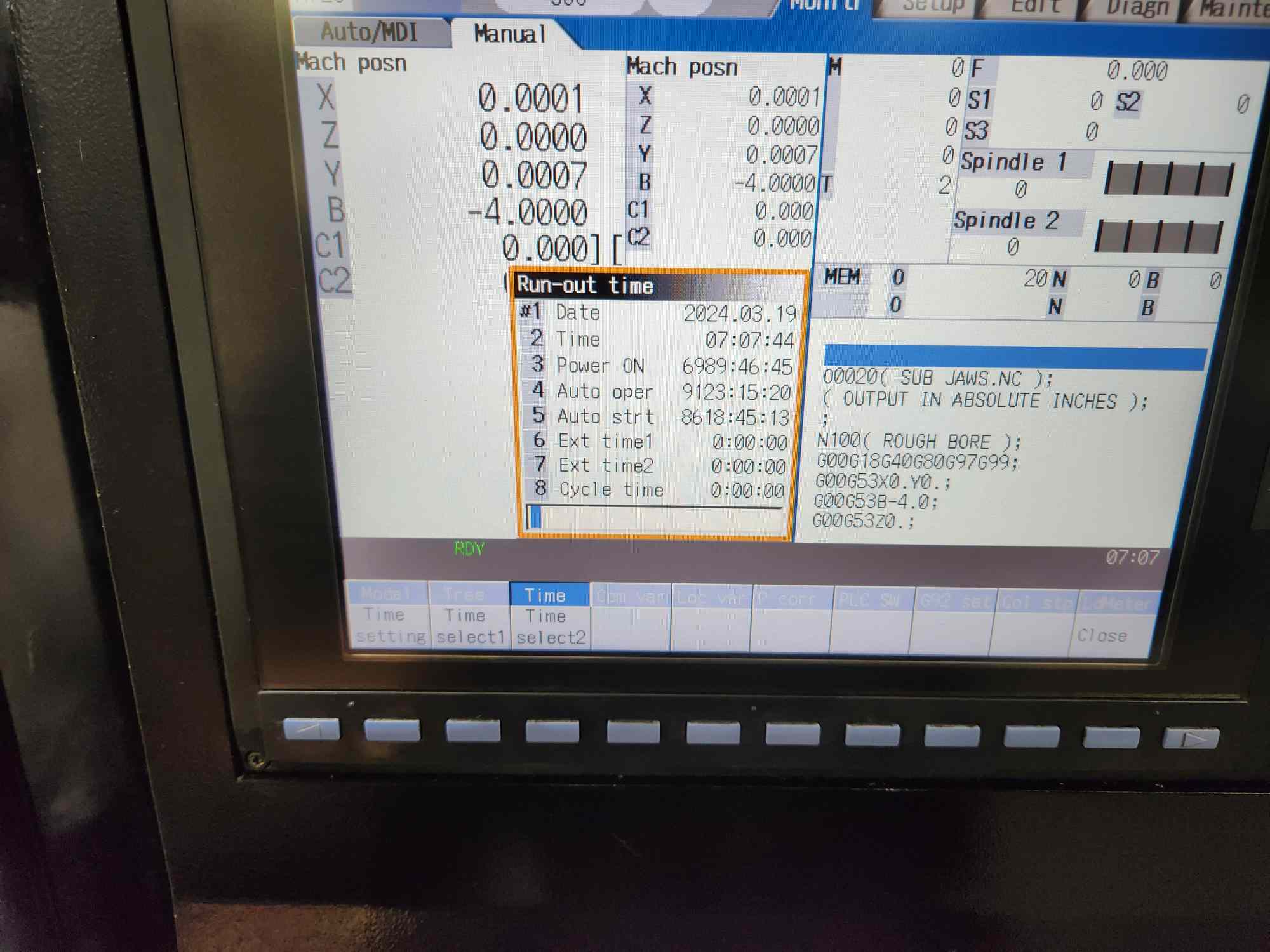

Mitsubishi M720 CNC Control

32-GB USB memory or the data server

G-Code or EIA programming

NC Monitor2 software allows any networked machines are monitored from a PC in

the office.

NC Explorer

NC Trainer Plus

Program Restart

G-code Guidance

Machining Condition Selection

Navi Lathe

MTConnect

High Speed-High Accuracy Mode G05 P10000; With one of the fastest processors

in the Industry the control can run programs up to 135,000 blocks per minute

with 680-block look-ahead

SSS (Super Smooth Surface) solves the problem of creating smooth pathes

Machine: 145″ x 80″ x 84″ 17,650 lbs

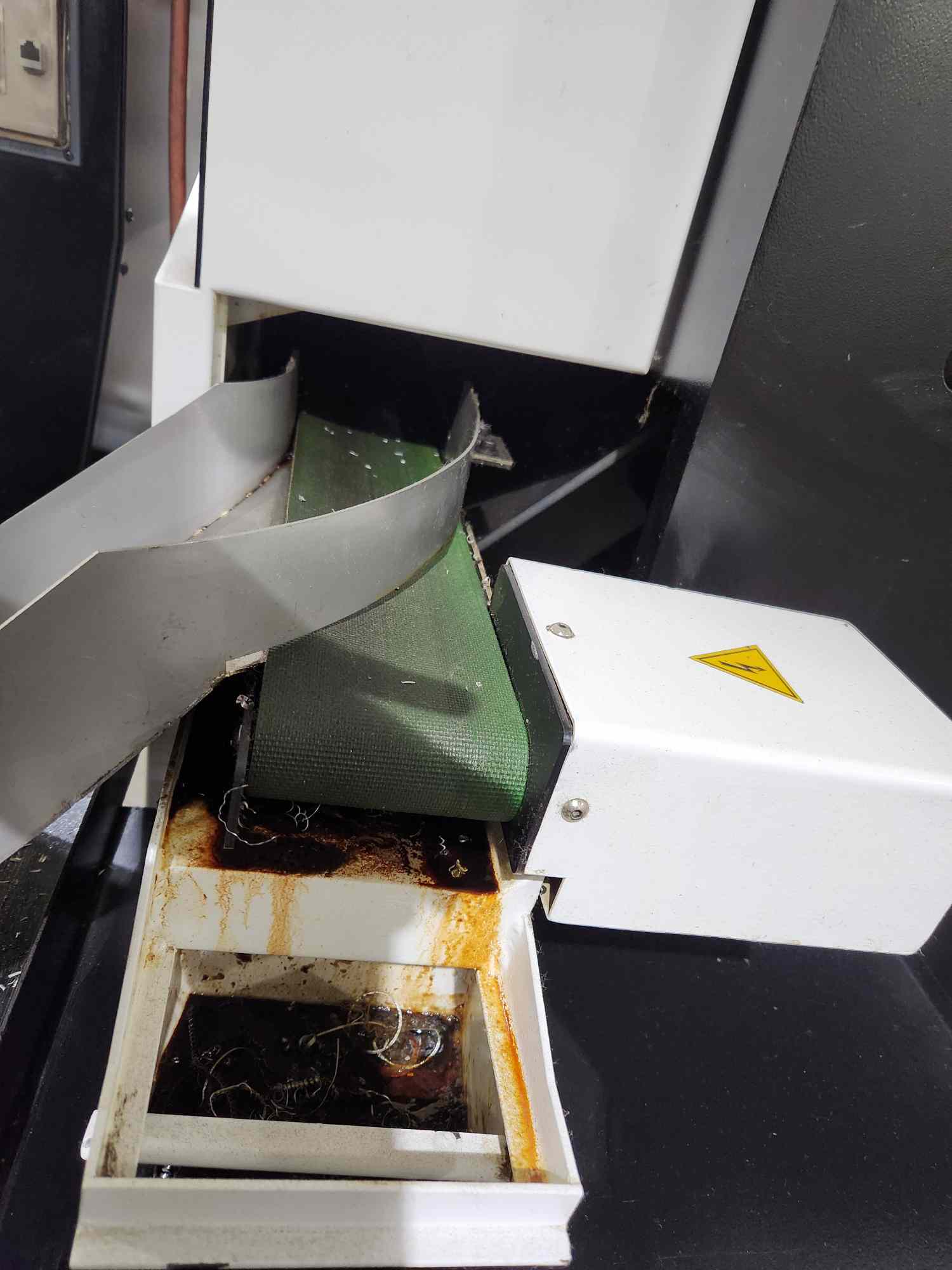

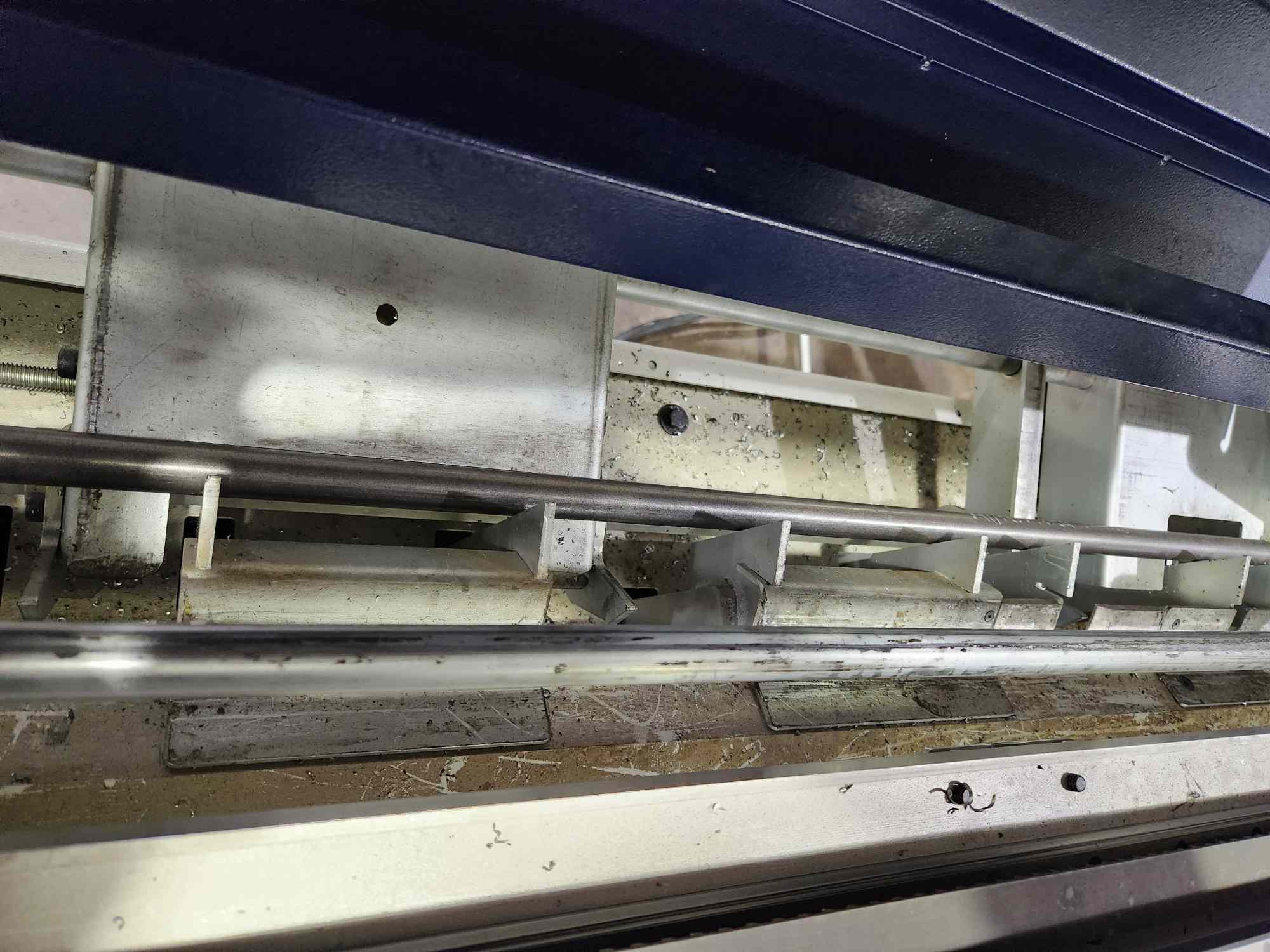

Chip Pan/Conveyor: 186″ x 67″ x 72″ 2,500 lbs

Orion Cooler Unit: 32″ x 19″ x 48″ 361 lbs

Equipped with:

Parts catcher

Chiller

Bar Feeder

Tool Setter

2 3 Jaw Chucks

2 Collet Chucks

Spindle Liners

Live tool Holders

Chip Conveyor

All specifications are assumed to be correct but must be confirmed by the purchasing entity.