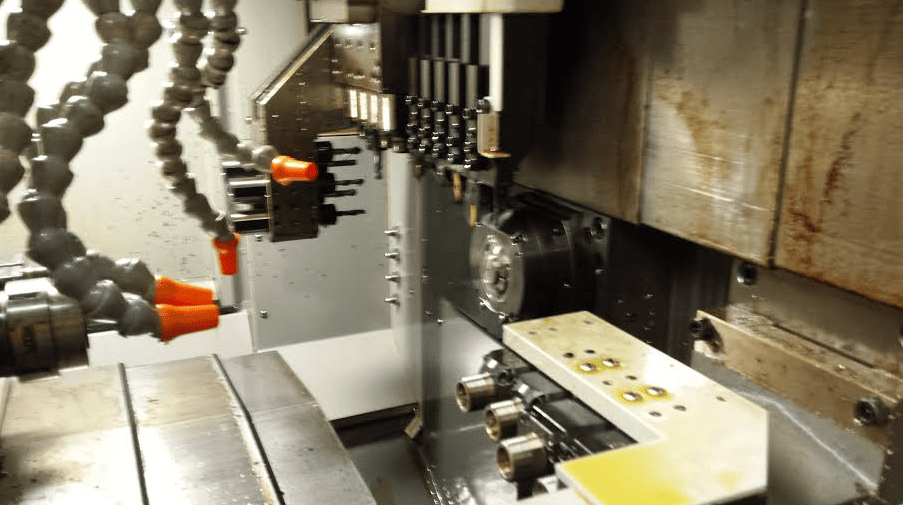

Hanwha XD32H CNC 7-Axis Swiss Lathe, 2008 – Low Hours, MTA Bar Feeder

$84,900.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: Swiss-Type Lathes

Make: Hanwha

Model: XD32H

Year: 2008

Machine Location: Upon Request

Stock #: 032787

Machining Capacity:

Maximum Bar Capacity Round: 1.250”

Maximum Bar Capacity Hex: 1.062”

Maximum Bar Capacity Sub-Spindle: 1.250”

Tapping Capacity Main Spindle: 0.312”

Front Ejection from the Sub-Spindle: 3.000”

Rear Ejection from the Sub-Spindle: 11.000”

Drilling Capacity on the Sub-Spindle: 0.393”

Tapping Capacity on the Sub-Spindle: 0.312”

Drilling Capacity on the Cross Drill: 0.275” / 0.393”

Tapping Capacity on the Cross Tap: 0.250”

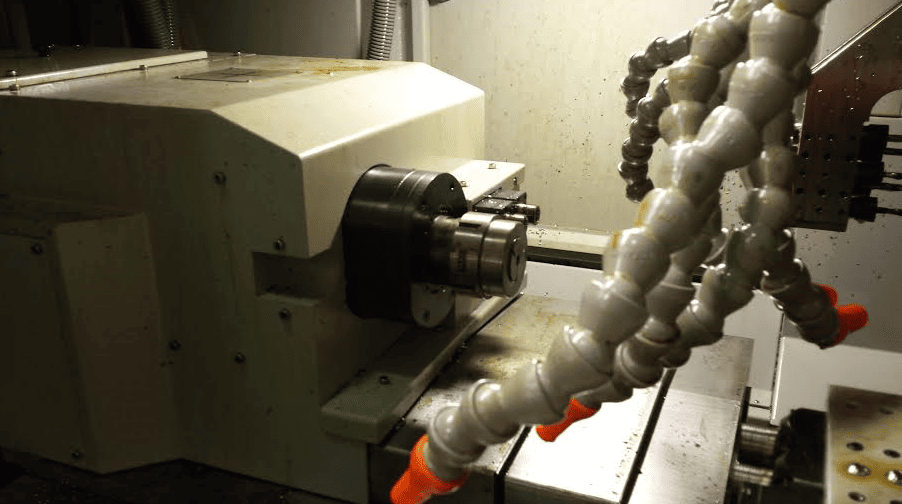

Main Spindle:

Spindle Speed: 300 to 8,000 RPM

AC Spindle Drive Core Motor (Chilled): 7.5 HP

C-Axis Control Minimum Programmable Angle: 0.001 Deg.

C-Axis Locking Gear: Every 1.0 Deg.

Z1-Axis Horsepower: 2.0 HP

Z1-Axis Stroke: 12.500”

Z1-Axis Rapid Traverse: 1,200 IPM

Sub-Spindle:

Spindle Speed: 300 to 7,000 RPM

AC Spindle Drive Core Motor: 3 HP

C-Axis Control Minimum Programmable Angle: 0.001 Deg.

C-Axis Locking Gear: Every 1.0 Deg.

Z2-Axis Stroke: 12.500”

Z2-Axis Rapid Traverse: 1,200 IPM

Z2-Axis Horsepower: 2.0 HP

Cross Working Spindles:

Spindle Speed: 200 to 6,000 RPM

AC Spindle Drive Geared: 1.7 HP

Tool Position:

O.D. Tool Positions:5

O.D. Tool Shank: 0.625” Sq

Cross Mill / Drill Stations: 4

Main Spindle I.D. Tool Positions Total (ER-16 Type): 7

-5 Stationary from the Main Tool Stand

-2 Powered Face Mill / Drill stations independent from the Main Tools

Sub-Spindle I.D. Tool Positions Total (ER-16 Type): 9

-5 Stationary from the Main Tool Stand

-2 Stationary Independent from the Main Tools

-2 Gear Driven Independent from the Main Tools to 6,000 RPM

Coolant / Lubrication Systems:

Coolant Pump Motor: 0.6 HP

Coolant Tank Capacity: 45 Gallons

Way Lube Tank Capacity: 0.48 Gallons

Machine Dimensions: 65″W x 94″L x 69″H

Weight 9,500 LBS

General Specifications:

Voltage: 3 Phase 200V-220V

Power Required: 30 KVA

Compressed Air: 80 PSI

Equipped With:

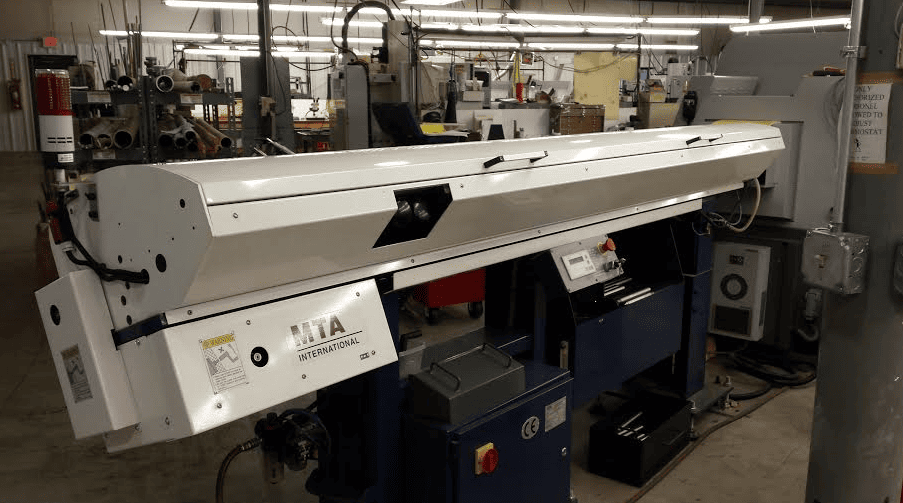

– MTA Eagle Bar Feeder

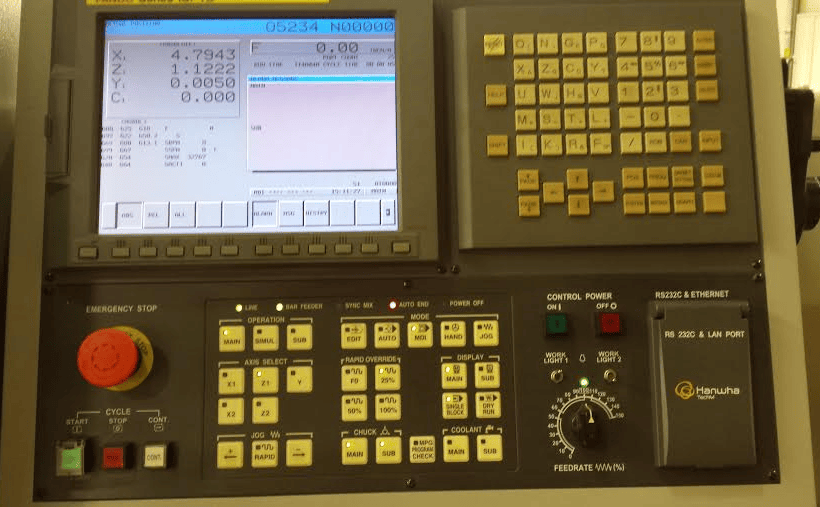

– Fanuc 18iTB System 2 Path

– Full C-Axis, Both Main and Sub Spindles

– Rigid Tapping

– Cross Drilling Unit

– Part Conveyor

– Part Separator

– Air Blow Unit

– Assorted Collets and Tooling

All specifications are assumed to be correct but must be confirmed by the purchasing entity.