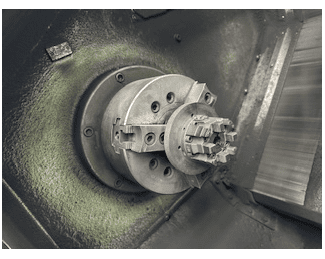

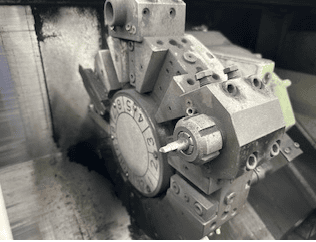

Okuma LB15C CNC Lathe, 1988 – Tailstock

$5,900.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: CNC Lathes

Make: Okuma

Model: LB15C

Year: 1988

Machine Location: Massachusetts

Stock #: 167389

MODEL: LB15C

NOMINAL SIZE: 400×500

CAPACITY

Number of controlled axes: 2

Swing over bed: 15.75 in.

Max turning diameter: 8.27(without talkstock spec: 9.84) in.

Max work length 19.69 (without tailstock spec: 9.06) in.

MAIN SPINDLE

Spindle diameter 3.94 / 2.20

Spindle nose ASA A2-6

Internal taper of spindle: MT No.6

Range of spindle speed: 70~3800 (Auto. 2 ranges x Infinitely variable) RPM

CROSS-SLIDE & CARRIAGE

Cross-slide travel (X-axis) 5.91 in

Longitudinal travel (Z-axis) 20.47 in

Cutting federate 0.0001-40.000 (both axes) HP

TURRET: Type and No. f tool stations: Auto Vert v12

HYDRAULIC TAILSTOCK:

Quill dia./stroke : 3.54/4.72 in

Center Taper : MT No.5

MAIN MOTOR: AC 10/15 (cont./30 min.) HP

FLOOR PSACE: 74×108 in

NET WEIGHT: 9900 lbs

———————————

STANDARD SPECIFICATIONS OF OSP5000L

• X, Z simultaneous 2-axis control

• Positioning, linear interpolation and circular interpolation.

• Position feedback of closed loop system by OSP absolute

position encoder (no zero return required).

• Tape format of N4 G2 X+44 Z+44 l+44 K+44 F+34 P+4 S4

• Photoelectric bi directional tape reader, 200 cps.

• Tape code of ISO (R840) or EIA (RS-244A) switchable.

• Combined use of absolute/incremental programming.

• Minimum input increment: 0.0001 in. for both X-(in dia.)

• Maximum input dimension: +9999.9999 in. (8-digit decimal

• Programmable unit: Selectable by parameter 1 or

0.0001 in. units.

• Direct feedrate programming in IPR or IPM

Feedrate override from 0 to 200% in 13 steps.

• Dwell: 0.01 to 9 9 9 9 9 . 9 9 sec.

• Tool selection: Max. 12 stations

• Tool offset selection: 32 pairs. Max. offset value: +9999.9999 in.

• Automatic tool offset calculation.

• Tool nose radius compensation.

• Direct spindle rpm command: 4-digit S command.

• Constant cutting speed control.

• Spindle speed override: In 50 to 200% range.

• Max. spindle rpm limitation: To set high rpm limit.

• Manual functions: Spindle CW/jog/CCW, turret index,

coolant ON/OFF, manual jog feed, spindle speed range

• Miscellaneous functions: Single block, machine lock, block

delete, optional stop, dry run, overtravel release, etc.

• CRT graphic/character display.

• Status indication.

• Memory mode operation.

• Multi-task functions.

• Self-diagnostic functions.

• Sidauto manual mode & auto restart.

• Darieting on flat, tol of et, travel limit, chuck

• Arc radius direct program function.

• Taper angle direct program function.

• Automatic chamfering.

• Theading lead range from 0.0001 to 40.0000 in.

• Thread cutting by fixed cycle (G33/G32) and non-fixed cycle

• Chamfering ON/OFF in thread cutting.

• Feed hold during thread cutting.

• Inch thread cutting by specifying number of threads.

• Special fixed thread cutting cycle.

• Grooving cycle program in one sequence.

• Drilling cycle program in one sequence.

• Lathe auto-programming function (LAP)

• User task 1: For GOTO and IF statements, arithmetic

operations, extensive address characters,

common variables, and local variables.

• User task 2: Subprograms (CALL, RTS, MODIN, and

MODOUT statements), trigonometric functions

(SIN, COS, TAN, square root, plus logics), and

system variables (zero offset, tool offset).

• FACIT puncher interface (for 8-bit parallel and RS232C).

• Chuck open/close by M codes.

• Tailstock quill advance/retract by M codes.

• Interactive graphic MDI function (IGF)

All specifications are assumed to be correct but must be confirmed by the purchasing entity.