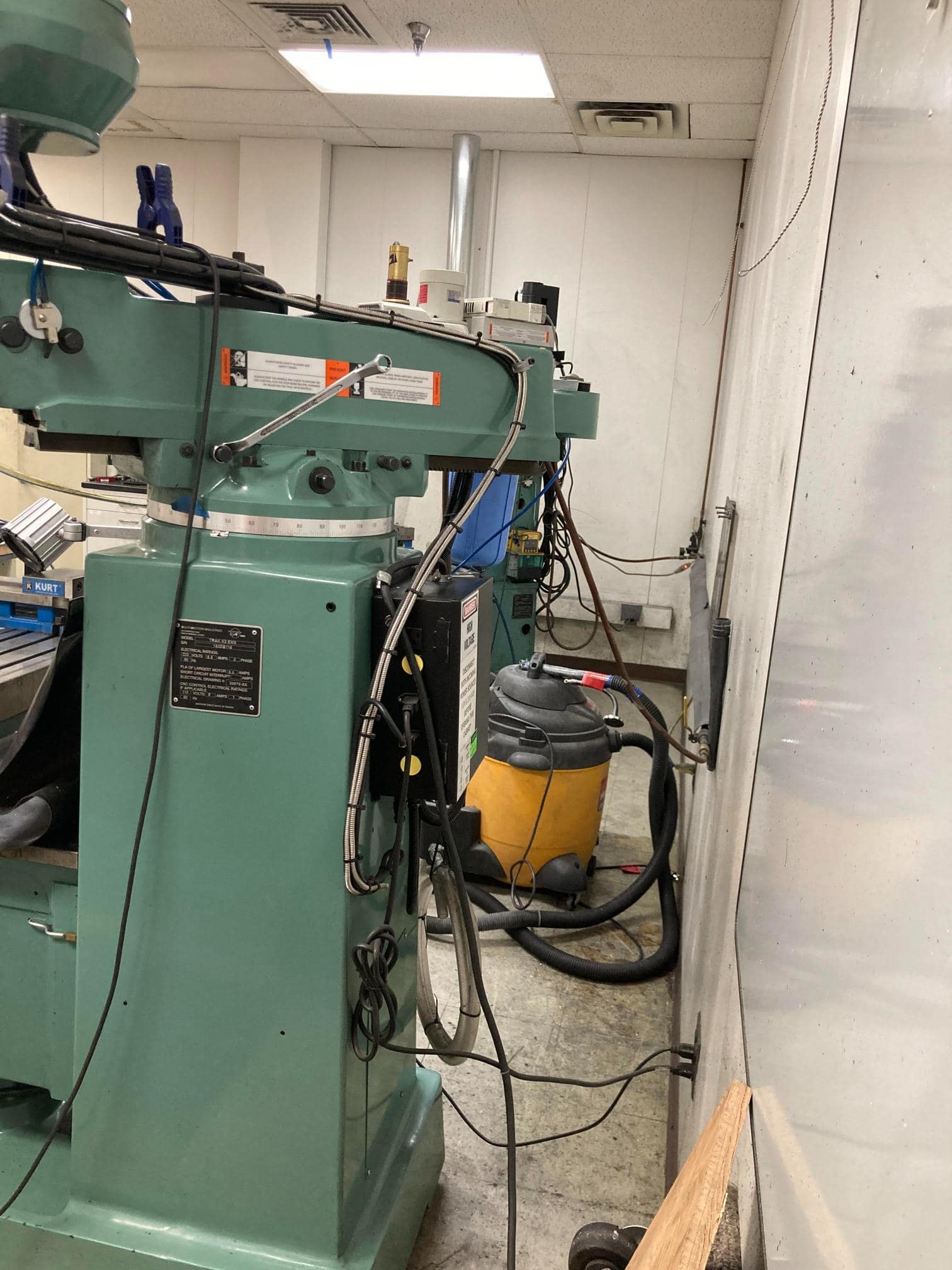

Southwestern Industries TRAK CNC Knee Mill K3EMX, 2016 – EMX CNC Control, RSG, PDB, spray/mist coolant

$12,000.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: CNC/Manual Knee Mills

Make: TRAK

Model: K3EMX

Year: 2016

Machine Location: New Jersey

Stock #: 354291

• Table Size –50” X 10”

• T-Slots – 5/8” x 3 x 2 ½”

• Table Travel – 32”

• Saddle Travel – 15.5”

• Knee Travel – 16”

• Ram Travel – 24”

• Maximum Quill Travel – 5”

• Quill Diameter – 3 3/8”

• Spindle Taper – R8

• Spindle Speed Range – 60-4200 RPM

• Head Tilt – 45 deg. forward, 45 deg. back, 90 deg. left, 90 deg. right

• Spindle Motor – 3 HP

• Power Requirement Control – 110V; 1P; 10A

• Power Requirement Machine – 220/440V; 3P; 8.5/4.25A

• Maximum Weight on Table – 750 lbs.

• Machine Weight – 2816 lbs.

• Machine dims l,w,h, – 71” x 59” x 84”

• Maximum rapid feed – 100 IPM

• Way surface type – Dovetail X, Z Square Y

• Precision 7207 CP4 spindle bearings

• Chrome hardened and ground quill

• Meehanite castings

• Slide ways are Turcite coated

• Wide way surfaces are hardened and ground

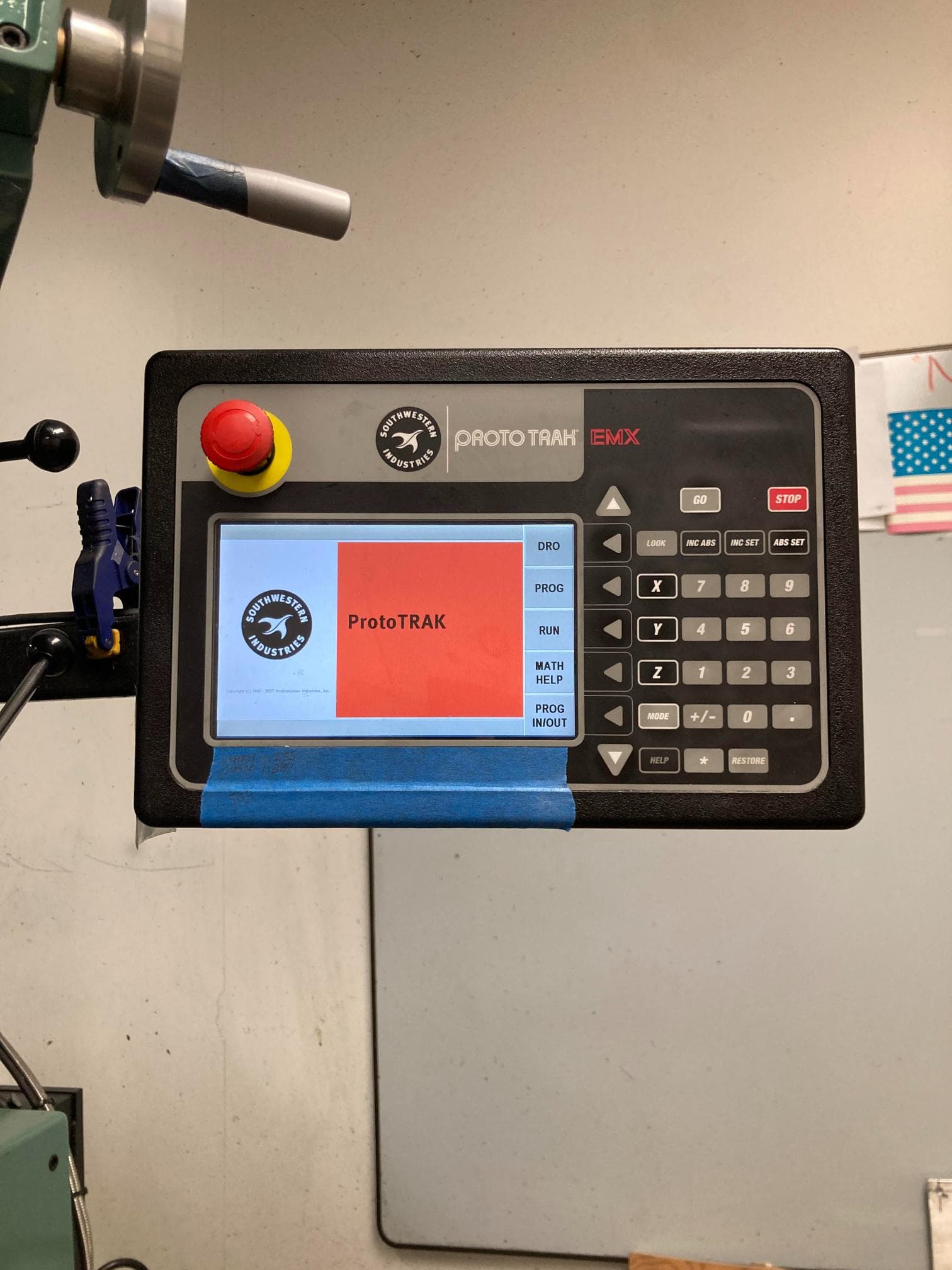

ProtoTRAK EMX CNC

Control Hardware Specifications

• Two-axis CNC, three-axis DRO

• Digital Servo Amplifiers – custom designed for ProtoTRAK operation

• D.C. Servo Motors – rated at 280 in-oz. Continuous torque are twice that required

• Precision Ground Ball Screws – in the table and saddle

• Modular Design – simplifies service and maximized uptime

• 115V/60HZ/15 amps

• Feedrate Override of programmed feedrate and rapid

• Polycarbonate Sealed Membrane Keypad and Gasket Sealed Control

• Enclosures to lock out contamination

• 2 USB ports for interface with a storage device

• 7.0” color LCD with adjustable contrast

• Rugged Industrial PC

Software

• Part geometry programming – the tool path is generated for you automatically

• Diameter Cutter Compensation – allows programming of the part rather than the center of the tool path

• Circular interpolation – makes arcs and any size hole easy to do with standard tools

• Linear Interpolation – to machine lines at any angle

• Conrad – provides automatic corner radius programming with one data input

• Incremental and Absolute – programming can even be mixed within an event

• Error Messages – to identify programming mistakes

• Fault Messages – for system self-diagnostics

• Program Downloading – from offline CAD/CAM systems via a modified FANUC 6 post-processor

• Teach – to program manual position and mill moves

• Parts Graphics display

• Look – a single button press to view graphics during programming

• Math Help – for finding points in a prompted format with graphical representation of prompts

• Machine Tool Error Compensation and Backlash Compensation custom set on mill after installation

• Selectable Inch/mm measurement readout

• Jog of X and Y from 1 to 100 inches per minute

• Continue Mill to eliminate repetitive data inputs while programming

Programmed Canned Cycles

• Posn/Drill – single point

• Bolt Hole – series of points evenly spaced around a circle

• Mill – straight line in any direction

• Arc – any portion of a circle

• Pocket – a rectangle or circle and all the material inside, includes finish cut

• Frame – a perimeter of a rectangle or circle, includes finish cut

• Repeat – of programmed events with or without offset

All specifications are assumed to be correct but must be confirmed by the purchasing entity.