Make an Informed Decision: Top Stretch Wrapper Questions

Stretch wrappers are essential tools in the world of packaging, offering efficiency and reliability in securing loads for transport or storage. If you’re considering investing in stretch wrappers for sale, whether for industrial or commercial use, you likely have some burning questions. In this article, we’ll address the top 5 questions about stretch wrappers to help you make an informed decision.

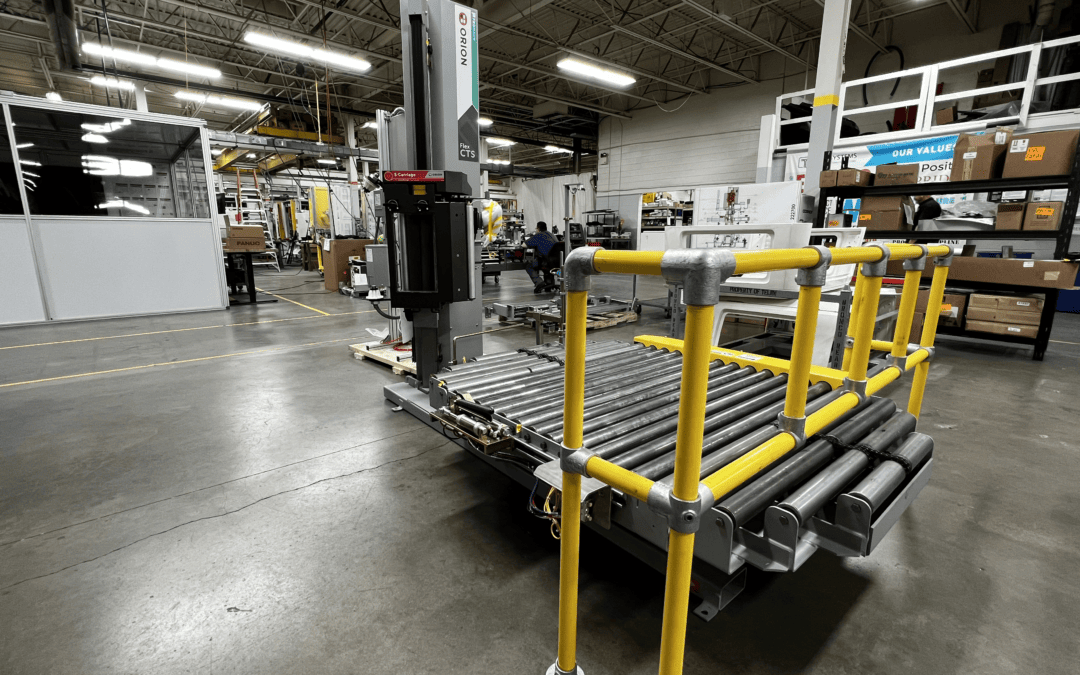

What are stretch wrappers, and how do they work?

Stretch wrappers are machines designed to wrap stretch film around items, typically palletized loads. They work by rotating the load while dispensing stretch film, ensuring even and secure wrapping. The film’s elasticity allows it to stretch, providing excellent load stability and protection against dust and moisture.

What types of stretch wrappers are available?

There are primarily two types of stretch wrappers: manual and automatic.

Manual Stretch Wrappers: These are suitable for small-scale operations. Operators manually control the wrapping process, walking around the load as they apply the film. Manual stretch wrappers are cost-effective and easy to use for light-duty applications.

Automatic Stretch Wrappers: These machines automate the entire wrapping process, offering higher efficiency and consistency. They are ideal for industrial and commercial settings with high-volume packaging needs.

What are the benefits of using industrial stretch wrappers?

Industrial stretch wrappers, designed for heavy-duty applications, offer numerous advantages:

- Time Efficiency: They can wrap large loads quickly, reducing labor costs.

- Load Security: Industrial wrappers provide superior load stability, minimizing the risk of damage during transit.

- Cost Savings: Efficient wrapping reduces film usage, saving on material costs.

- Consistency: Automated systems ensure uniform wrapping, reducing the risk of product damage.

How do commercial stretch wrappers benefit businesses?

Commercial stretch wrappers cater to a wide range of businesses, including retail stores, warehouses, and distribution centers. Here’s how they benefit businesses:

- Efficient Operations: Commercial wrappers streamline packaging processes, enhancing overall efficiency.

- Product Protection: They safeguard products from external factors such as dust and moisture.

- Professional Presentation: Neatly wrapped pallets create a professional image for customers and partners.

- Cost Reduction: By minimizing film waste and labor, commercial wrappers contribute to cost savings over time.

What factors should I consider when choosing a stretch wrapper for sale?

When shopping for a stretch wrapper, several factors should influence your decision:

- Load Size: Consider the dimensions and weight of your typical loads.

- Production Volume: Determine your daily or hourly packaging requirements.

- Space Constraints: Ensure the machine fits within your workspace.

- Budget: Set a realistic budget and compare options within your price range.

- Film Type: Select the appropriate stretch film for your specific application.

Conclusion

In conclusion, stretch wrappers play a crucial role in modern packaging, offering efficiency, load security, and cost savings. Whether you need an industrial or commercial stretch wrapper, understanding your needs and considering the factors mentioned will help you choose the right machine. Remember, investing in the right stretch wrapper can significantly impact your packaging operations’ success and efficiency.

If you’re ready to explore stretch wrappers for sale, contact reputable suppliers who can provide guidance based on your unique requirements.