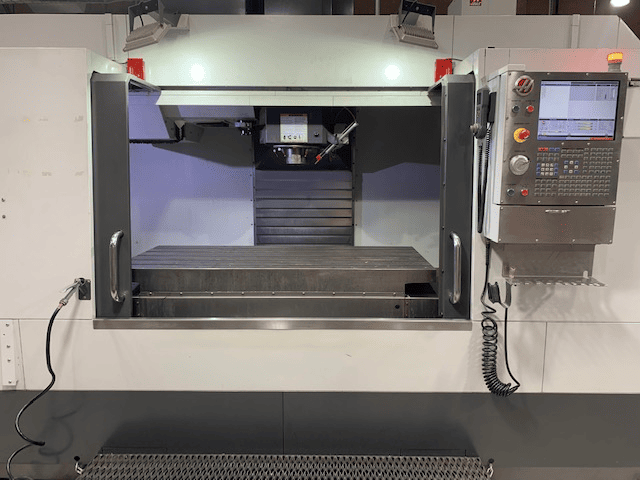

Uncompromising Value & Quality: Haas VMCs

Around 30 years ago, Haas Automation, Inc. developed their first vertical machining center in the United States. They named this machine, the VF-1, which stood for “Very First One”. This model series would eventually end up being one of the world’s most popular VMCs.

Haas Automation’s vision has always been to build high performance machines right here in the USA for a fair price. To this day, they have built over 200,000 machine tools! They sell a very large selection of lathes, rotary tables, VMCs, HMCs, as well as fully integrated automation solutions like automatic parts loaders, pallet-pool systems, and 6-axis robotic systems. Their used machines are almost just as popular as when they were new! We’re covering the top models of Haas vertical machining centers below.

Haas VMC Top Models

The VF-series is the most popular VMC model that Haas offers. They have been building the VF series since 1988 so there are many different variations of the machine. Haas categorizes their vertical machining centers by small, medium and large.

Small:

The small category includes the 40-Taper Mills (VF-1, VF-2, VF-2TR, VF-2SS, VF-2YT, VF-2SSYT), Super Speed (VF-2SS, VF-2SSYT) and a 5-Axis Mills (VF-2TR). Want to see a VF-2SS in action? Check out this video by Haas Automation that shows this machine’s cutting ability.

Medium:

The medium category includes the 40-Taper Mills (VF-3, VF-3SS, VF-3YT, VF-3SSYT, VF-4, VF-4SS, VF-5/40, VF-5/40TR, VF-5SS, VF-5/40XT, VF-3SS, VF-3YT, VF-3SSYT, VF-4, VF-4SS, VF-5/40, VF-5/40TR, VF-5SS, VF-5/40XT), Super Speed (VF-3SS, VF-3SSYT, VF-4SS, VF-5SS), 50-Taper Mills (VF-3YT/50, VF-5/50, VF-5/50TR, VF-5/50XT), and the 5-Axis Mills (VF-5/40TR, VF-5/50TR).

Large:

The large category includes the 40-Taper Mills (VF-6/40, VF-5SS, VF-6/40TR,p VF-7/40’s through VF-12/40’s and a VF-14/40), Super Speed (VF-6SS), 5-Axis Mills (VF-6/40TR, VF-6/50TR), and the 50-Taper Mills (VF-6/50’s through VF-2/50’s and a VF14/50).

Standard Options & Add-Ons

All Haas VMC’s have a flood coolant ring that comes standard on their machines and is considered the backbone of the cooling system. This provides a large amount of coolant that lubricates the cutting area as well as clearing away any debris.

They also have an optional programmable coolant nozzle called the “P-cool”. This nozzle can be programmed for each tool you use in your program, no matter the size.

There is also an optional through spindle coolant system that is available in a 300 PSI or 1000 PSI configuration. It is very effective when drilling deep holes or pockets.

Haas also offers through-tool air blast as an add-on to the TSC system. Through-tool air blast delivers high-pressure air through the tool, instead of coolant. This clears the area of debris from the cutting zone before they are cut a second time. When through-tool air blast isn’t an option, you can use the auto air gun option. This is an alternate way to move chips away from the tool or can be used in addition if you need more air to remove the debris.

Another feature you can add on is the minimum quantity lube option. This is best used when you can’t use water-based coolant but you still need to keep the tool lubricated. It will measure out a precise amount of lubricant and deliver it to the tools cutting edges.

Summary

Haas vertical machining centers are always in high demand in the used machinery industry. Here at Revelation Machinery, we always have a large selection of used Haas VMCs for sale. Connect with our CNC experts today to find the right Haas VMC machine for your shop!

Have used Haas vertical machining center equipment sitting idle? Let Revelation Machinery take it off your hands. Find out how to sell used Haas VMCs for cash today!