Miller PerformArc PA550HW Robotic Welding Cell, 2013

$79,900.00

This specific product is no longer available, however we may have other similar or identical products in stock. Please utilize our search function at the top of the page to check and confirm, or fill out the form below:

Head / Tail Distance of 60″

Swing Diameter of 40″

550 Lb. Payload Per Side

Servo Indexing Table (Load / Unload)

Common Base Permits Easy Relocation

Compact Design Minimizes Floor Space

Single Source: ONE CALL: Miller Welding Automation

1.0 Standard Equipment: Fully Assembled and Wired

1.1 Cell Construction

Fully Fabricated Steel Tubular Frame with Sheet Metal Wall Structure

Framework is Unitized; the Main Robot/Positioner/Controls Section Can be Picked up From the Front or Back Sides for Placement and Relocation

All Cables are Run in Discrete Paths or Under Deck Plates or Above Entrance/Exit Points to Prevent Premature Wear From Welding Spatter or Contact with Personnel

All Lower Cableways are Covered with Deckling to Eliminate Tripping Hazards and Protect the Cables From the Welding Environment

To Prevent Tripping, the Framework is Cut out Near the Maintenance Cccess Doors

Two Sliding Maintenance Access Doors are Included for Easy Robot Maintenance and Programming Access

Robot Riser with Robot Pre-Assembled, Dressed and Mounted

Robot Controller, Welder and Heavy Power Connections Including Transformers (if needed) are Pre-Wired and Pre-Assembled to Run to a Provided Single Electrical Disconnect Box at the Rear of the Work cell

System Paint Color of standard Black

Fork Lift Access for Easy Transport

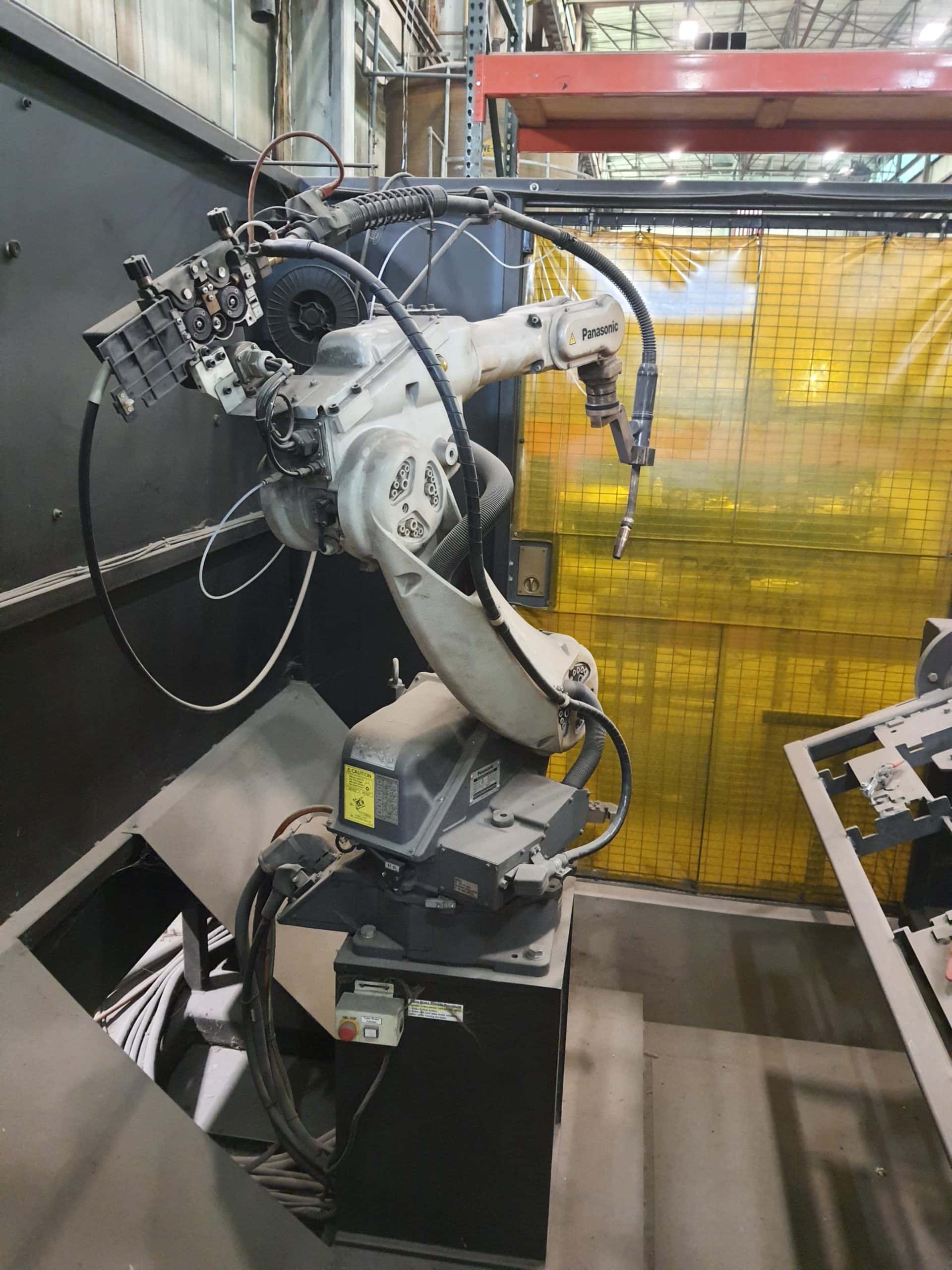

Panasonic YA-1 T AR81 UO6 Robot

8kg Payload

62.9 inch Reach to Point P

Panasonic G3 Robot Controller

Panasonic G3 Teach Pendant (Windows CE 7″ Color GUI)

Automatic Program Backup – Standard

SD/USB ports – Standard

Collision Detection – Standard

Brake Releases on Arm – Standard

Second and Third Axis Over Travel Switches, Limiters and Electrical Circuits – Standard

Servo Power on Lamps – Standard

1.3 Cell Controls

Heavy Electrical Power Pre-Wired and Assembled, Including Common Electrical Disconnect

Light Curtains in L-shape Configuration at the Front of the Work Cell

External Axis Brake Release Circuit and Enabling Box

Standard Panasonic Cell Controls

Start Strip is Mounted to the Vertical Tube to Minimize Opportunity to be Damaged During Production

1.4 TAWERS 350A 60% Duty Pulse, 80% CV

TAWERS 350 Amp welding systems come standard with Embedded Arc Control (EAC) technology which eliminates the need for three separate control systems and fuses control of the robot, welder and servo wire feeder into a single physical unit.

This new controls breakthrough is contained entirely internal to the robot controller and is monitored by the TAWERS 64-bit main CPU. EAC technology controls not only the robot motion path and sequence commands, but simultaneously synchronizes the welding power supply waveform control and servo wire feeder response accordingly, to adjust and correct for dynamic changes in the welding process.

TAWERS with EAC technology goes far beyond conventional digital communication systems, delivering the first and only generation of fully software-controlled robotic welding solutions.

SP-MAG is a new welding process developed out of industry needs for a more versatile CV welding process. Where conventional and even high-end CV processes have tried to produce low-spatter, high-speed welds, they have missed the mark ultimately demanding lower amperage levels or slower welding speeds to achieve their goals. TAWERS has successfully met these challenges by bringing together the major benefits of Pulse and CV into one process SP-MAG

Ultra-low spatter levels

Low heat input

Low susceptibility to arc blow

Wide process windows across entire amperage range

Excellent thin material and gap handling capability

Spatter is the enemy of every company, big or small. The TAWERS solution takes aim at not only the arc physics that generate spatter, but also other factors that

directly impacts spatter generation. SP-MAG combined with advances in welding arc starting and ending have led to an extreme decrease in the amount of spatter generated during the entire welding process. Extensive testing has shown that a switch from conventional CV to SP-MAG could result in a savings of 100 to 150 lbs less wire purchased per arc.

Reduced or eliminated secondary cleanup operations saving manpower, floor space and limiting total work in process

Using a 100 kHz primary side high frequency inverter, TAWERS offers an extremely fast response, providing exceptionally precise, almost real time, and control of the welding arc.

10-5 sec (10 micro second) control and correction cycle

5X faster response than conventional feedback control circuits

Electronic reactor control makes special process inductance taps a thing of the past. Optimum current control during all phases of welding is now possible.

1.5 Step-Down Transformer

The system comes pre-wired to a single disconnect box, with input power of 480 volts, 3 phase, 60 amps suggested service (single robot systems). Other input voltages can be accommodated at an additional cost.

1.6 Operator Control Center

Robot handles all safety supervision through concurrent I/O

PLC used to simplify wiring

Operator Macros for Tip Change and Tip Check

Full Safety Monitoring includes Light Curtains for Operator

1.7 Safety Equipment

Perimeter Guarding – Solid and Wire Mesh Fence Panels

Yellow Arc Curtain Included on Wire Mesh Panels

Dual Safety Sliding Gates – Interlocked

Arc Screen Provided on Turntable

Light Curtain Operator Intrusion Protection

1.8 Tregaskiss 500 Amp Air Cooled clamping Torch

500 Amp Air cooled torch

Accurate and Durable gooseneck maintains a repeatable tool center point

The thick-walled aluminum gooseneck resists bending during collisions.

The sleek design improves accessibility into tight work zones

The hand nut makes maintenance easy -no tools required for neck replacement

1.9 Turntable & Positioners – 3 Axis

A-B Station Servo Indexing Axis

Servo Positioner

Main axis 180 index time of approximately 3.2 seconds

Fully welded H-frame assembly connecting the headstock and tailstock section for rigidity and long term repeatability

120mm through hole on main axis for utilities passage

Arc screen rotates with the h-frame and tooling (user provided)

Outboard Positioners (2)

Panasonic Servo Positioners

550-lb capacity per side (see manual for loading details)

55mm through hole on outboard positioners for utilities passage

Headstock to tailstock length of ~60″

Rotation diameter of ~40″

All axis fully servo driven, not limited to indexed positions

Servo-disconnect technology to comply with latest safety standards. Removes power to outboard (operator side) servo when the light curtains are breached

Remote Jog option included

Allows the operator to safely rotate the load side fixture during normal operation

Typically needed when an operator needs to load parts in more than one load position