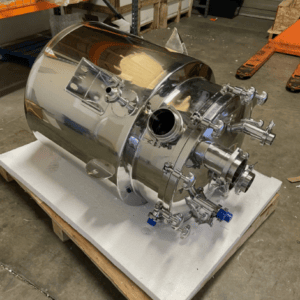

Stainless Steel Tanks

Used Stainless Steel Tanks

Revelation Machinery provides used stainless steel tanks for sale, used in the food and beverage industry, and for other process applications. Our tanks range from as low as 400 gallons up to 20,000 gallons, although we often have stainless steel tanks exceeding this range. Check back often for new arrivals, and subscribe to our mailing list for updates.

If you don’t find the tank you are looking for, please contact us, and we’ll help you find what you need. You can also sell your used steel tank quickly and easily with Revelation Machinery!

Found Results

Process Industry Essentials

Stainless steel tanks are widely used in the process industry due to their numerous benefits, such as high durability, corrosion resistance, and ease of maintenance. Common uses of these tanks in the process industry include:

- Liquid Storage

- Mixing and Blending

- Fermentation

- Processing and Production

- Transportation and Distribution

Types of SS Tanks

Several different types of SS tanks are used in the processing industry, each designed to meet specific needs and requirements. Here are some of the most common types of used stainless steel tanks for sale:

SS Storage Tanks: These tanks store liquids such as water, chemicals, oils, and beverages. They can be vertical or horizontal and insulated or non-insulated.

SS Mixing Tanks: Used to mix and blend liquids and solids in the processing industry. They often have internal agitators or mixing blades to ensure the contents are well-mixed.

SS Fermentation Tanks: These stainless steel tanks ferment beer, wine, and dairy products. They are often designed with specific features such as cooling jackets and pressure relief valves.

SS Reactors: These tanks are used in chemical reactions or processes that require heating or cooling. They are often designed with heating or cooling jackets and agitators to ensure the contents are well-mixed.

SS Pressure Tanks: Designed to withstand high pressures and are used in a wide range of applications, including water treatment, chemical processing, and the storage of compressed gases.

Stainless Steel Silos: These large stainless steel tanks are used for the storage of bulk materials such as grain, cement, or chemicals. They can be horizontal or vertical and may have multiple compartments for storing different materials.

Portable SS Tanks: These used stainless steel tanks for sale are designed for transportation and are often used in the food and beverage industry to transport liquid products such as milk and juice.

Classifications of Stainless Steel Tanks

General classifications of used SS tanks include:

Single-Walled Tanks: These tanks have only one layer of stainless steel and no additional insulation or protection. They are commonly used for storing non-hazardous liquids or materials that do not require special temperature control.

Double-Walled Tanks: Double-walled tanks have two layers of stainless steel, with an insulation layer between them. They are designed to provide an extra layer of protection against leaks or spills and help maintain the temperature of the stored material.

SS Clad Tanks: SS Clad tanks have a layer of stainless steel bonded to a layer of another material, such as carbon steel or aluminum. They are often used in applications where the stored material requires the corrosion resistance of stainless steel, but the tank itself does not need to be entirely made of stainless steel.

Jacketed Stainless Steel Tanks: An outer layer, or jacket, surrounds the tank. This jacket circulates a heating or cooling fluid to maintain the temperature of the material inside the tank. The jacket can be either single or double-walled, with the double-walled jacket providing an additional layer of insulation.

The jacketed design allows for precise temperature control and is commonly used for heating, cooling, and maintaining the temperature of liquids, semi-solids, and viscous materials. Different types of jacketed used stainless steel tanks are available for sale, including dimple jacket tanks, half-pipe jacket tanks, and conventional jacket tanks.

Stainless Steel Process Tanks: Designed for use in a specific process or application, such as mixing or blending of materials, or for holding materials temporarily before they are processed or transferred to another tank or vessel.

High-Pressure Tanks: Designed to withstand high-pressure environments, such as those found in the oil and gas industry or in chemical processing applications.

Compressed Air Tanks: They store compressed air commonly used in industrial applications to power tools and equipment. These tanks are designed to withstand high-pressure environments and are often built to meet specific safety standards.

Benefits of Used Stainless Steel Tanks

Corrosion Resistant: Highly resistant to corrosion, stainless steel is an ideal material for equipment used in the processing industry. This resistance to corrosion means tanks can last for many years without needing to be replaced.

Hygienic: SS tanks are easy to clean and maintain, which is important in the processing industry, where hygiene is critical. Stainless steel is non-porous, which means bacteria and other contaminants cannot easily penetrate the tank’s surface.

Durability: These tanks are highly durable and can withstand harsh conditions such as extreme temperatures and high pressure, making them suitable for various processing applications.

Versatile: Stainless steel tanks are highly versatile and can be used for various applications. They can be designed to meet specific requirements such as size, shape, and capacity.

Cost-Effective: While SS tanks may be more expensive than tanks made from other materials, they offer long-term cost savings due to their durability and resistance to corrosion. This means that SS tanks don’t need to be replaced as frequently as tanks made from other materials.

Recyclable: Stainless steel is a highly recyclable material, which means that at the end of its life cycle, it can be recycled and used to make new products. This makes it an environmentally friendly choice.

Factors To Consider When Purchasing a Used Stainless Steel Tank

Material Grade: SS tanks are available in various grades, each with their unique properties and characteristics. The choice of grade will depend on the specific application and the level of corrosion resistance and durability required. Grades widely used in the fabrication of SS tanks include 304/304L, 316/316L, and Duplex.

Capacity & Size: The capacity and size of the used SS tank will depend on the amount of material that needs to be stored or processed. Choosing an appropriately sized tank for the application is vital to avoid wasting resources or having insufficient capacity.

Pressure & Temperature Requirements: Some processing applications require tanks that can withstand high pressure or temperature. Choose a stainless steel tank that meets the application’s specific pressure and temperature requirements.

Agitation Requirements: Some applications require SS tanks that can agitate or mix materials. To ensure the desired mixing or blending level, choosing a tank with the appropriate mixing or agitation system is essential.

Hygiene Requirements: Hygiene is critical in industries such as food and pharmaceuticals. Choosing a tank that is easy to clean and maintain and meets the industry’s hygiene standards is important.

Installation & Maintenance Requirements: The tank should be easy to install, maintain, and repair, with readily available spare parts and knowledgeable technicians available for support.

Cost: The cost of the stainless steel tank should be considered along with its features and benefits and should be balanced with the tank’s long-term cost savings, durability, and lifespan.

Contact Us to Get Started

Please contact us if you have any questions about the used stainless steel tanks for sale here, or if you need to find a specific brand/type. Interested in selling your surplus stainless steel equipment? Let Revelation Machinery help you find the right buyer.