One of the first lathe machines with a mechanical cutting tool and set of gears dates all the way back to the 1700’s! Fast forward to almost 2021 and we have some of the most advanced CNC machinery available in the United States. Machining has evolved significantly to meet the demands of the manufacturing industry, even as recent as this past decade. The advancement of CNC programming has made owning a CNC lathe the key to a productive manufacturing facility.

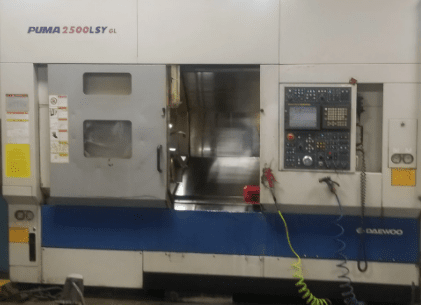

CNC Lathe machines assist in removing metals from the workpiece to make a desired part for production. These machines are used to perform various operations such as facing, cutting, knurling, reaming, boring/counter boring, grooving, forming, threading, drilling and turning. The biggest advantage to CNC machinery is the computer programming available to assist in automating the production process as much as possible.

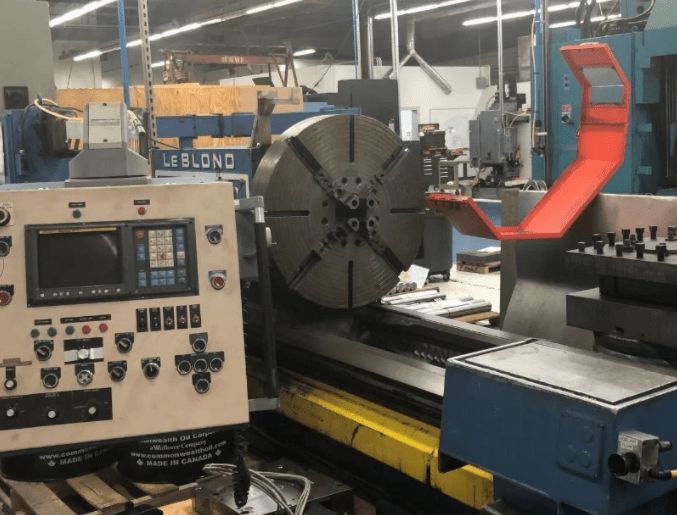

What are some of the main types of Lathes? There are many types of lathes available depending on the type of work to be performed. There are Vertical Turret Lathes, Swiss Lathes, Engine Lathes and Multi Axis Lathes. Some brands of these lathes include but are not limited to Haas, Okuma, Hyundai, Hurco, Doosan and Mazak. Below are the types of lathes you can find with a short description on each!

- Vertical

Turret Lathes- Vertical Turret Lathes are easy to use, can withstand a heavy workload and are ideal for repetitive production of identical products. These lathes are great for mass production as they can produce multiple identical pieces in a short amount of time. This lathe has a turret that can hold various tool boxes which also positions the blade against the piece at the right pressure and position to be precise. Vertical Turret lathes can have multiple tooling attached for boring, drilling, facing, or thread cutting.

Turret Lathes- Vertical Turret Lathes are easy to use, can withstand a heavy workload and are ideal for repetitive production of identical products. These lathes are great for mass production as they can produce multiple identical pieces in a short amount of time. This lathe has a turret that can hold various tool boxes which also positions the blade against the piece at the right pressure and position to be precise. Vertical Turret lathes can have multiple tooling attached for boring, drilling, facing, or thread cutting. - Swiss Lath

es– Swiss lathes are great when you need a smooth surface finish! They actually eliminate the need for multiple cuts when you are using one heavy cut. Swiss lathes can have up to four tools cutting at the same time. This lathe has a holding mechanism that is recessed behind a guide bushing. The guide busing provides additional support to the stock material while it is being turned. It also has the ability to turn small sized parts and parts that have a large length-to-diameter ratio.

es– Swiss lathes are great when you need a smooth surface finish! They actually eliminate the need for multiple cuts when you are using one heavy cut. Swiss lathes can have up to four tools cutting at the same time. This lathe has a holding mechanism that is recessed behind a guide bushing. The guide busing provides additional support to the stock material while it is being turned. It also has the ability to turn small sized parts and parts that have a large length-to-diameter ratio. - Engine Lathes– E

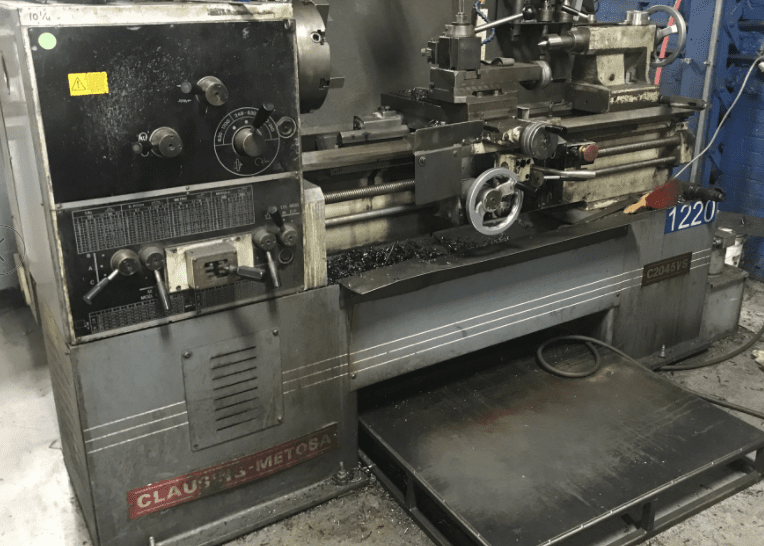

ngine Lathes are one of the oldest types of lathes and have been used since the 19th century. These lathes are best used for individual part production or parts modification. They have a gearbox which contains multiple spindle speeds and also contains a carriage that supports the cutting tools. Engine lathes have high safety standards as well as being easy to operate.

ngine Lathes are one of the oldest types of lathes and have been used since the 19th century. These lathes are best used for individual part production or parts modification. They have a gearbox which contains multiple spindle speeds and also contains a carriage that supports the cutting tools. Engine lathes have high safety standards as well as being easy to operate.

- Multi Axis La

thes– Multi Axis Lathes are faster, flexible, best for mass production and have a higher accuracy than most machines. They provide more flexibility for the spindle to move. Each axis has a motor attached that can move the spindle. An example would be a 3-axis, this allows you to move up/down, forward/backward and right/left.

We here at Revelation Machinery have a large selection of lathes available in our inventory. If you have any questions about CNC lathe machines or need to find a specific brand or type, please feel free to contact us!

thes–

thes–