Vertical Turret Lathes

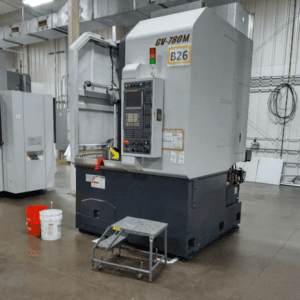

Used Vertical Turret Lathes For Sale

Please view the regularly updated inventory of used Vertical Turret Lathes below. Inventory includes a variety of brands, sizes, and capacities. Below is our up to date selection of used Vertical Turret Lathes. Our brands include but are not limited to: Hurco, Doosan, Okuma, Mazak and much more. If you don’t find the Vertical Turret Lathe you are looking for, please contact us!

Revelation Machinery can help you find what you need! If you have any questions about Vertical Turret Lathes or need to find a specific brand/type, please feel free to contact us! If you need to sell your used Vertical Turret Lathe, do so here.

Found Results

CNC lathe machines assist in removing metals from the workpiece to make a desired part for production. These machines are used to perform various operations such as facing, boring, cutting, knurling, reaming, counter boring, chamfering, parting off, grooving, forming, taper turning, threading, undercutting, eccentric turning, drilling and turning. They are used for metal spinning, metal working, wood turning, and glass working, to name a few.

The lathes are composed of a headstock, spindle, chuck, tool post, tailstock, hand wheel, bed, lead screw, chip pan, carriage, apron, saddle, cross slide, guideways, feed rod, and a leg. The headstock holds the gear train, chuck, gear speed control levers, feed controllers, and the main spindle. The lathe will spin the material in a spindle while the cutting tool works to cut the workpiece. Some benefits to using a lathe are accuracy and the ability to perform repeatable production jobs.

A Vertical Turret Lathe is also known as a vertical boring mill and is equipped with a turret. These lathes have the material held on a horizontal table that will rotate along a vertical axis. The material also will rotate around the Y-axis while the head moves linearly and a turret slide that is mounted on a cross rail that can vertically or horizontally feed non-rotating tools.

Some shops may choose a Vertical Turret Lathe over an Engine Lathe due to the Engine Lathe being heavy and harder to set up. The Vertical Turret Lathes can work on larger material as well. Vertical Turret Lathes are best for mass production jobs where repetitive production of duplicate parts is a factor. They are useful when working with large, heavy, short workpieces. The machines can be used in several different industries, such as for jobs where they must cut material into small parts for a toy making production process.

Below are some benefits of choosing a Vertical Turret Lathe:

- High Accuracy

- Ideal for repetitive production of identical products

- Smooth finishing

- Precision

- Can be used with a variety of materials

- They are fairly easy to use

- They are made to withstand a heavy workload.

Now, with all the benefits there are some disadvantages, as with most machines. A disadvantage of a CNC Vertical Turret Lathe would be that it is not able to cut metals that are round in shape. Another disadvantage is that they use a lot more electricity due to the power they have and require much more space in the shop.

Revelation Machinery can help you find what you need! If you have any questions about Vertical Turret Lathes or need to find a specific brand/type, please feel free to contact us! If you need to sell your used Vertical Turret Lathe, do so here.