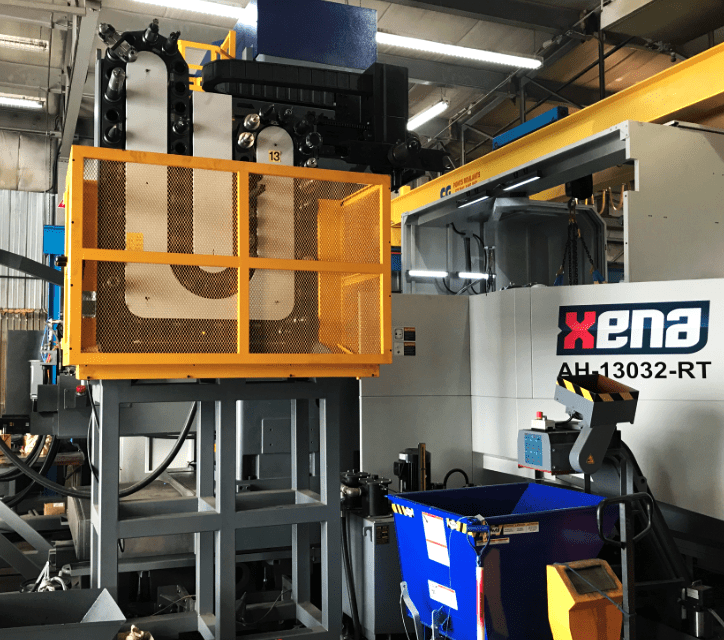

XENA 5A 5-Axis CNC Horizontal Boring Mill 130mm 3.2M, 2017

$619,900.00

Request a Quote to Instantly See Pricing

Call NowMachine Type: Boring Mills

Make: Xena

Model: 5A 130mm 3.2M

Year: 2017

Machine Location: Upon Request

Stock #: 151748

*Includes 1 Year Warranty

**Under 500 hours use

XENA TACHYON / FAGOR

3 modes on the same 15” touch screen.

– Manual mode

– Manual assisted mode TACHYON

– FAGOR 8070 “‘CNC’ ‘mode, conversational, or/and G code

– Controller: 5 simultaneous axis

Note that our TACHYON / FAGOR controller has the ” TeamViewer ” interface, by which it is possible to check and diagnose machine, remotely via the internet.

Avoiding costly, and often unnecessary technician traveling when it comes only to parameters and/or programming.

SPECIFICATIONS

Table: 72 ” x 63″

Max weight table 17,000 lbs

TRAVEL

X-axis 126″

Y-axis 78.7″

Z-axis 78.7″

W-axis 35.4″

Height of table : 56 ”

SPINDLE

Diameter 130mm (5.1)

Nose: BT-50 or CAT-50

Speed (RPM) 10 -2000

Spindle motor: (26HP @ 30 min)

Speed ratio 3 (gearbox)

FEED

Fast feed (X-Y-Z) 10M / min (472’’./min)

Fast feed (W): 6M / min (400’’/min)

Cutting feed: 5M / min (200’’/min)

Table ” B ”: 4 RPM

ATC

Number of tools: 60 tools (BT or CAT-50) ” ARM TYPE ” (currently on BT)

Max tool weight: 55 lbs

Max tool length: 15.7

Max tool diameter: 5 (10 in. Without adjacent tools)

Change time: 15 sec.

Machine weight: 118,000 lbs

Floor space: 295 x 301 ” (See attached drawing)

Height: 213.5 ”

Voltage: 440V 60Hz 3ph

Included :

Axis “B” @ 360,000 position (+/- 10 μ) with possibility of machining in 4 simultaneous axes on the table.

Spindle cooler

Automatic power off

Hydraulic unit

Coolant system

Automatic lubrication

Alarm light tower

LED full interior lighting

M.P.G. 5 axis

Linear positioning glass scale on the X, Y, Z axes

Heat exchanger

Chip conveyors

Other accessories included: (see details at the bottom of the pages)

PROBE Renishaw (RTS + RMP60 (Q) + RMI-Q) Automatic tool length & workpiece probing system

5th axis installed on table with base (see photos below)

(Central connection from the top of enclosure for full pivoting)

Possibility of (5 axis simultaneously).

Includes:

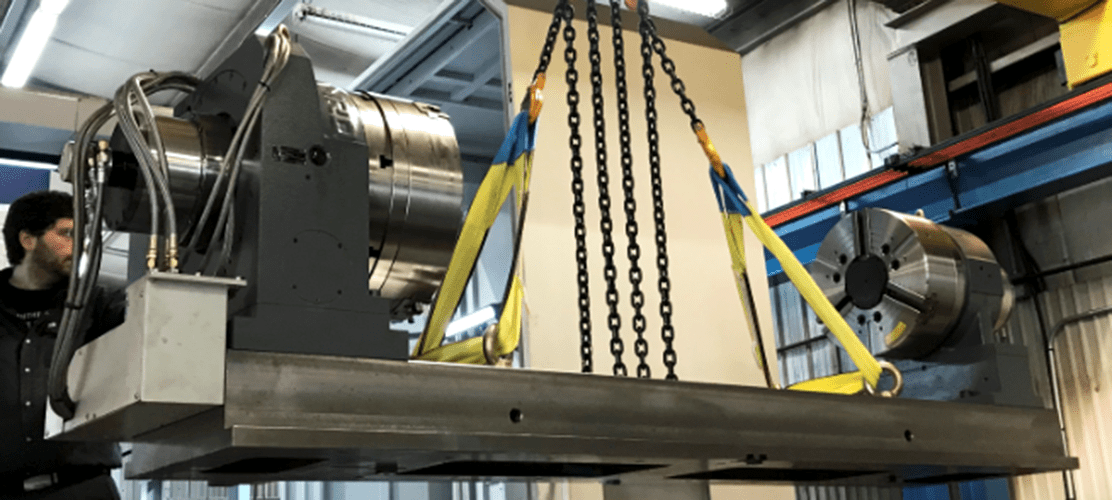

Rotary table with a 3-jaw hydraulic chuck (20 ”) with a 6 ” bore

HD rolling center with a 3-jaw hydraulic chuck (16 ”)

Hydraulic brakes on both ends

CTS “Coolant” High pressure through spindle) (15bar = 215 psi)

Full enclosure (required with CTS)

W 400mm extension support (for vibration-free power machining up to the center of the table) (See photos below)

Permanent adapter for: (combined with tool changer)

2 heads at 90 degrees: (1) mini 50/30 + (1) STD 50/50 (see photos below)

1 straight extension 50/50 (see photos below)

All specifications are assumed to be correct but must be confirmed by the purchasing entity.